Quick-dry rosin-based waterborne UV-curable paper surface sizing agent with high water resistance and preparation method thereof

A surface sizing agent and rosin-based technology, which is applied in the field of preparation of water-based surface sizing agents, can solve problems such as long-time drying, and achieve the effect of broadening applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

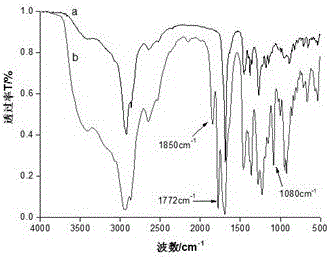

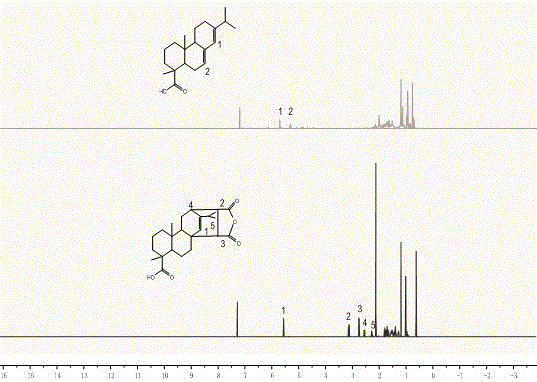

[0036] Step 1: add the maleopimaric acid of 20g in dry reactor (infrared spectrum and proton nuclear magnetic resonance spectrum are attached respectively figure 1 with 2 shown), 15mL of dichloromethane and 0.02g of N,N-dimethylformamide, at 0°C, dropwise add a mixture of 5.95g of thionyl chloride and 5mL of dichloromethane, drop it within 30 minutes, and then Heat up to 50°C and reflux for 6 hours;

[0037] Step 2: Cool down to 0°C, then slowly add 5g of polyethylene glycol to the above reactor, drop it within 30 minutes, and then quickly add 5g of acid-binding agent triethylamine. After the addition, react at 0°C for 2 hours, and react at 25°C for 4 hours, then evaporate the solvent under reduced pressure;

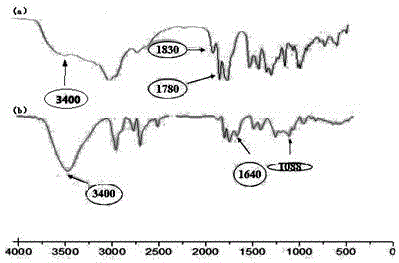

[0038] Step 3: Add 5.8g of hydroxyethyl acrylate, 0.15g of p-toluenesulfonic acid and 0.03g of hydroquinone into the above reactor, and react at 90°C for 3 hours to obtain prepolymerized rosin-based polyether acrylate Body, after infrared spectroscopy (as attached i...

Embodiment 2

[0042] Step 1: Add 20g of maleopimaric acid, 15mL of dichloromethane and 0.02g of N,N-dimethylformamide to a dry reactor, add 5.95g of thionyl chloride and 5mL of di The mixed solution of methyl chloride was dropped within 30 minutes, then heated to 50-℃ and refluxed for 6 hours;

[0043] Step 2: Cool down to 0°C, then slowly add 5g of polyethylene glycol to the above reactor, drop it within 30 minutes, and then quickly add 5g of acid-binding agent triethylamine. After the addition, react at 0°C for 2 hours, and react at 25°C for 4 hours, then evaporate the solvent under reduced pressure;

[0044] Step 3: Add 2.6015g hydroxyethyl acrylate, 0.0014g pentaerythritol tripropylene ester, 0.15g p-toluenesulfonic acid and 0.03g hydroquinone into the above reactor, blow nitrogen for 15 minutes, and then react at 90°C 3 hours, obtain rosin-based polyether acrylate prepolymer;

[0045] Step 4: cooling to 50° C., adding 6 g of neutralizing agent triethylamine to the rosin-based polyeth...

Embodiment 3

[0048] Step 1: Add 20g of maleopimaric acid, 15mL of dichloromethane and 0.02g of N,N-dimethylformamide to a dry reactor, add 5.95g of thionyl chloride and 5mL of di The mixed solution of methyl chloride was dropped within 30 minutes, then heated to 50°C and refluxed for 6 hours;

[0049] Step 2: Cool down to 0°C, then slowly add 5g of polyethylene glycol to the above reactor, drop it within 30 minutes, and then quickly add 5g of acid-binding agent triethylamine. After the addition, react at 0°C for 2 hours, and react at 25°C for 4 hours, then evaporate the solvent under reduced pressure;

[0050] Step 3: Add 0.15g p-toluenesulfonic acid and 0.03g hydroquinone into the above-mentioned reactor, ventilate nitrogen, then slowly drop the mixed solution of 2.6015g hydroxyethyl acrylate and 0.0014g pentaerythritol tripropylene into In the above reactor, the dripping is controlled within half an hour, and the reaction is carried out at 90° C. for 3 hours to obtain a rosin-based poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com