Method for removing dye in water by using sludge of water supply plant

A technology for sludge and water removal in water supply plants, which is applied in the field of environmental pollution and treatment, and achieves the effects of high adsorption efficiency, low cost, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

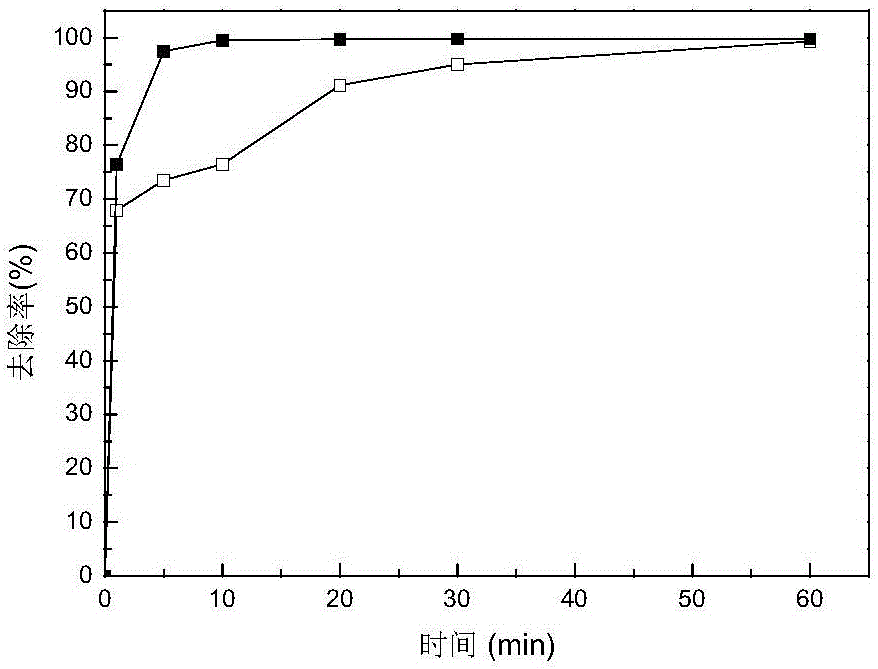

[0019] Such as figure 1 As shown, the dehydrated aluminum sludge from the water supply plant was selected, air-dried under natural conditions, and ground to obtain particles of 1-200 μm. Add 5g / L of aluminum sludge or activated aluminum sludge to 20ml of dye-containing water to be treated (congo red concentration 50mg / L), adjust the pH to 6.0, control the reaction time on a magnetic stirrer to 60min, and filter , The absorbance of the filtrate was measured with a spectrophotometer, and then the dye removal rate of the wastewater was calculated.

[0020] After testing, the dye concentration in the water before the treatment in this embodiment was 50 mg / L, and the dye concentration in the water after the treatment in this embodiment dropped to 0.5 mg / L and 0.1 mg / L respectively, and the removal rate of the dye reached 99% and 99.8 %. It can be seen that this embodiment uses aluminum sludge or activated aluminum sludge as an adsorbent to remove anionic dyes, with high removal e...

Embodiment 2

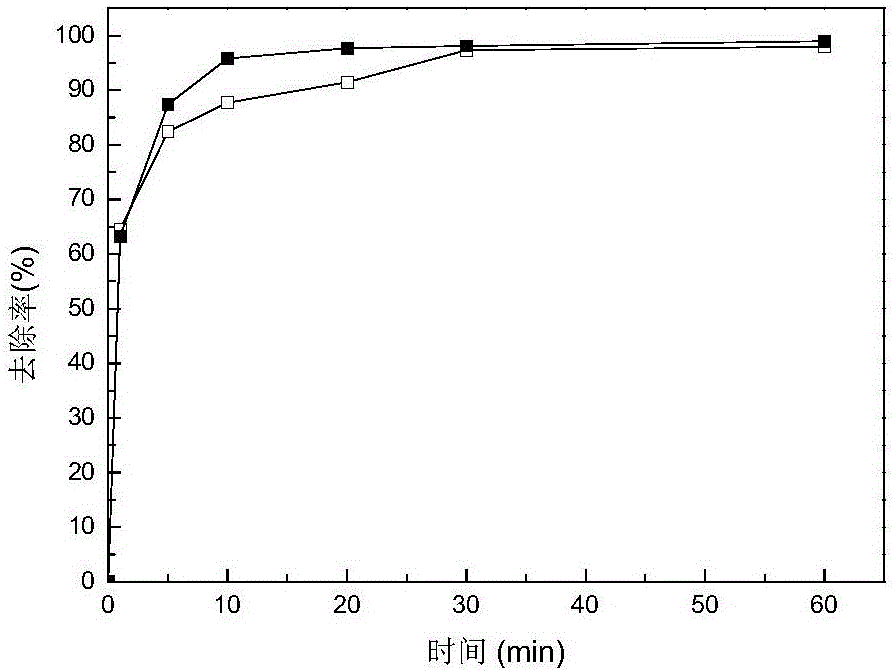

[0022] Such as figure 2 As shown, the dehydrated aluminum sludge from the water supply plant was selected, air-dried under natural conditions, and ground to obtain particles of 1-200 μm. Calcined in a muffle furnace at 300°C for 2h to obtain activated aluminum sludge. Add 5g / L of aluminum sludge or activated aluminum sludge to 20ml of dye-containing water to be treated (methylene blue concentration 50mg / L), adjust the pH to 8.0, control the reaction time on a magnetic stirrer to 60min, and filter the filtrate with The absorbance is measured by the spectrophotometer, and then the dye removal rate of the wastewater is calculated.

[0023] After testing, the dye concentration in the water before the treatment of this embodiment was 50 mg / L, and the dye concentration in the water after the treatment of this embodiment dropped to 1.0 mg / L and 0.5 mg / L respectively, and the removal rate of the dye reached 98% and 99%. %. It can be seen that this embodiment uses aluminum sludge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com