Dynamic focusing and heating system for particle suspension and heating method thereof

A dynamic focusing and heating system technology, applied in chemical instruments and methods, heating or cooling equipment, fluid dynamics tests, etc., can solve the problems of difficult laser penetration, insufficient energy transmission to specific areas, etc., to achieve application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

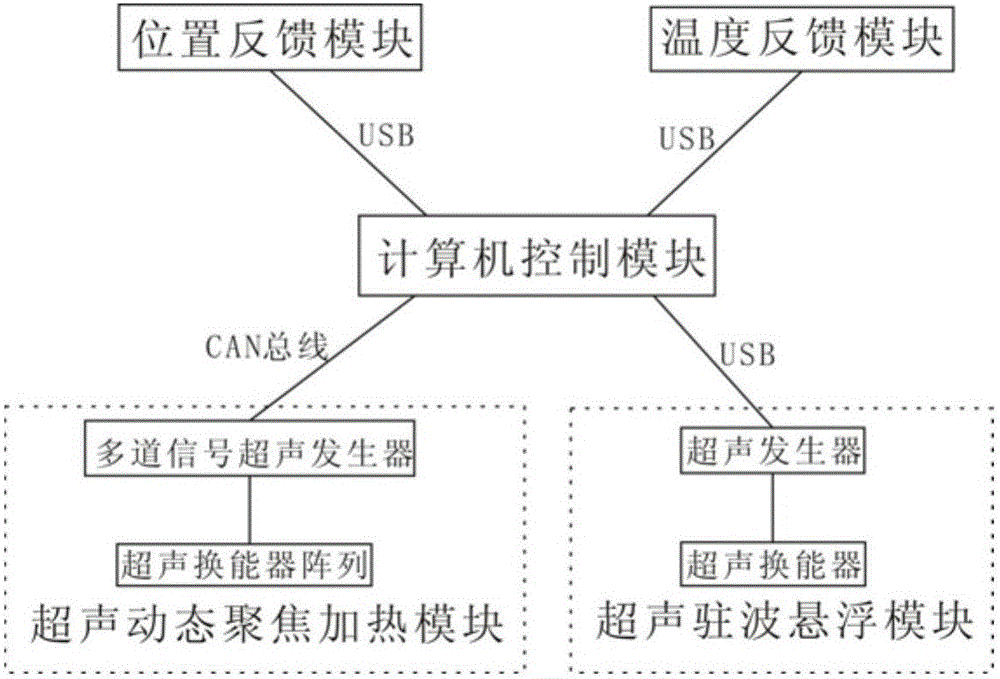

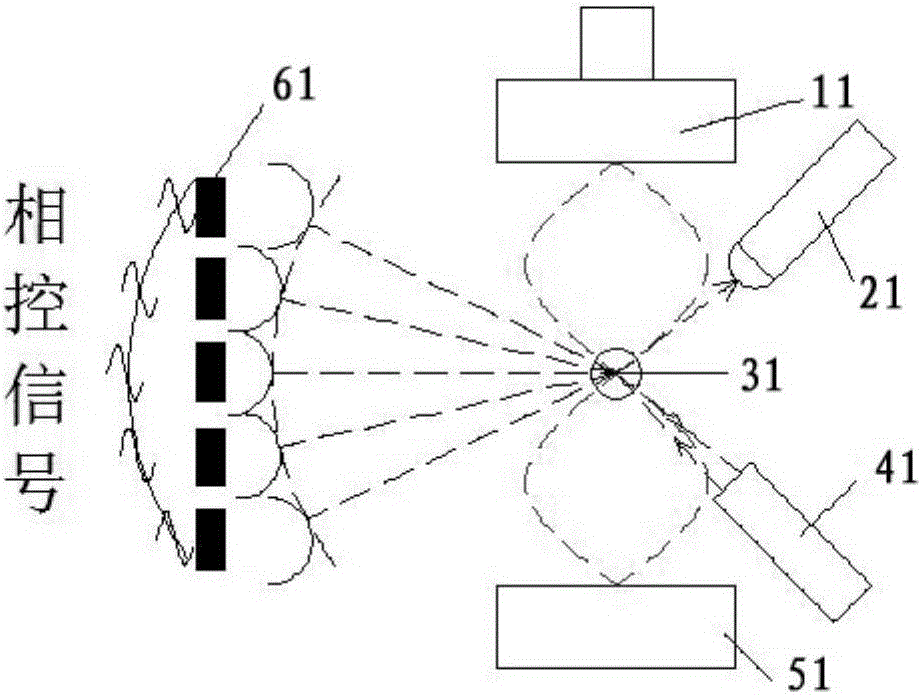

[0031] Such as Figure 1-3 As shown, the particle suspension dynamic focusing heating system of this embodiment includes a computer control module, a position feedback module, a temperature feedback module, an ultrasonic standing wave suspension module and an ultrasonic dynamic focusing heating module.

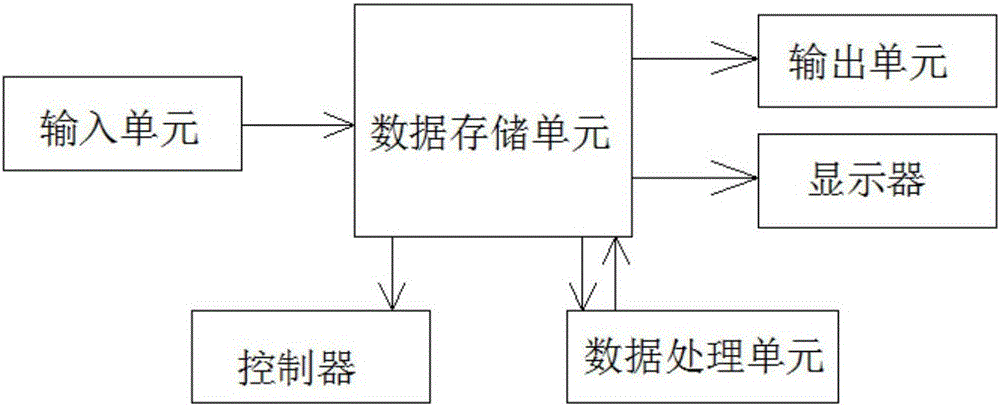

[0032] The computer control module includes an input unit, a data storage unit, a data processing unit, an output unit, a controller and a display. The input unit and the data storage unit are connected by an interface. The input unit completes the input of signals and stores them in the data storage unit. The data storage unit It is connected with the controller, data processing unit, output unit, and display through interfaces. The controller controls the data storage unit to complete the signal transmission to the output unit, display, and data processing unit. The data storage unit and the data processing unit complete the two-way transmission of signals. The storage unit ...

Embodiment 2

[0042] Such as Figure 4 As shown, the particle suspension dynamic focusing heating system of this embodiment is different from Embodiment 1 in that: the radiation end 12 of the transducer is a plane, and the reflection end 52 is a concave spherical surface, and the distance between the radiation end surface 12 and the reflection end surface 52 increases. Large; the distribution of the piezoelectric array elements of the multi-channel signal ultrasonic transducer array 62 is a 32×32 planar rectangular distribution, and a single array element is a rectangle with a size of 3×3mm, the distance between the array elements is 2mm, the power of a single array element is 2W, and the frequency is 1.5MHz For other structures, refer to Embodiment 1.

[0043] Based on the heating method of the particle suspension dynamic focusing heating system of the present embodiment, the two heating particles 32 are room temperature solid tin-bismuth alloys with a spherical diameter of 3 mm and a melt...

Embodiment 3

[0048] Such as Figure 5 As shown, the particle suspension dynamic focusing heating system of this embodiment is different from Embodiment 1 in that: the power of the ultrasonic generator is 2000W, the frequency is 45KHz, the radiation end 13 and the reflection end 53 of the transducer are both planes; The piezoelectric array elements of the signal ultrasonic transducer array 63 are distributed in a 64×64 planar rectangle, a single array element is a rectangle with a size of 3×3mm, the distance between the array elements is 2mm, the power of a single array element is 3W, and the frequency is 5MHz. Other structures refer to the implementation example one.

[0049] Based on the heating method of the particle suspension dynamic focusing heating system of this embodiment, the heating particle 32 is a normal temperature solid tin-bismuth alloy with a spherical diameter of 8 mm and a melting point of 58 degrees. The specific steps are as follows:

[0050] (1) The computer control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com