Glass fiber kiln pure oxygen combustion system and control method thereof

A glass fiber and combustion system technology, applied in glass furnace equipment, glass manufacturing equipment, glass production, etc., can solve the problems of inability to solve the purpose of the invention, reduce combustion efficiency, and high operating intensity, so as to reduce heat and harmful gases and dust , reduce glass foam dust, improve the effect of glass fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

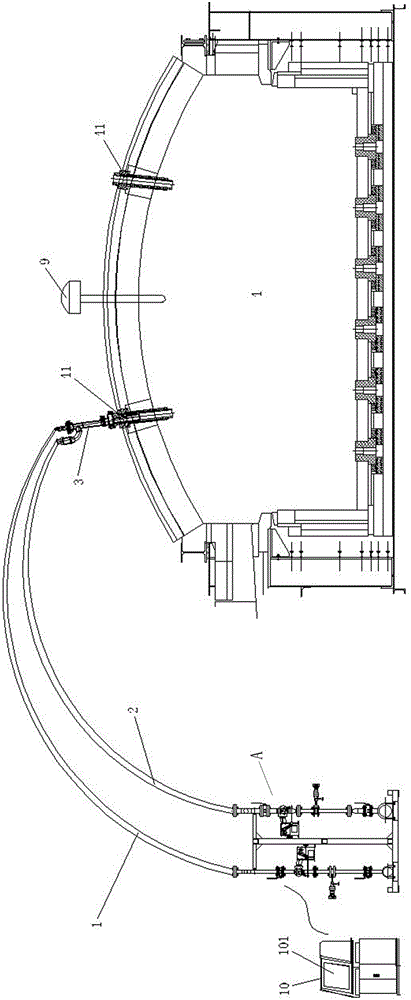

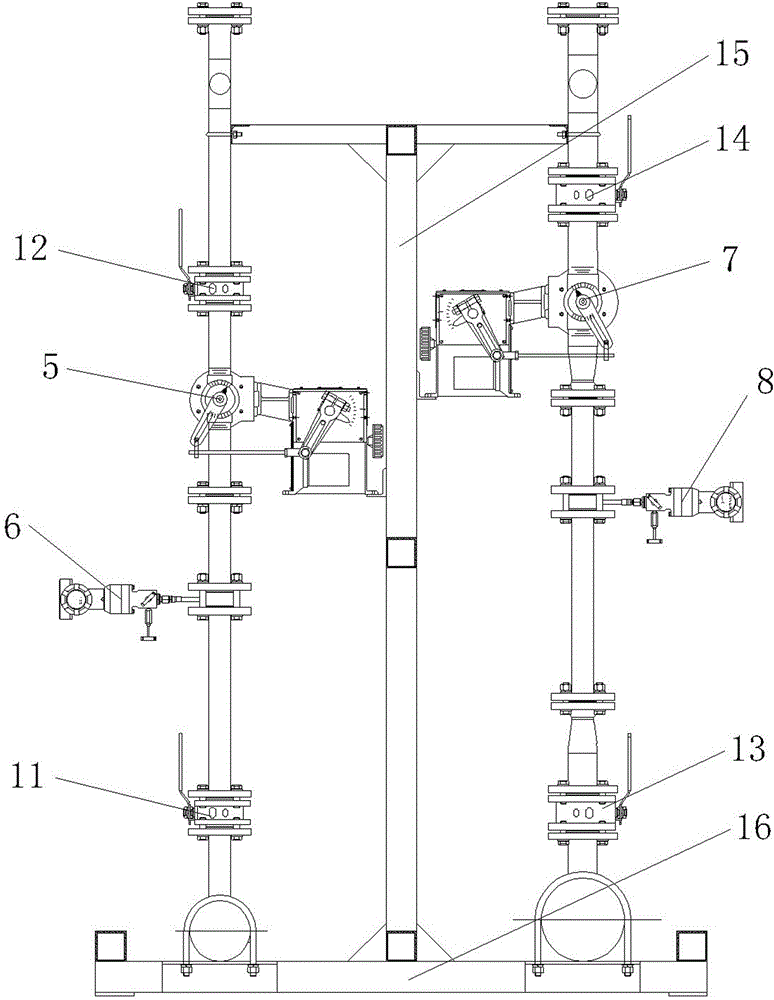

[0032] Such as Figure 1-3 As shown, the product of this embodiment includes a natural gas pipeline 1, an oxygen pipeline 2, a burner 3 and a fiberglass furnace 4, the natural gas pipeline 1 and the oxygen pipeline 2 are connected to the burner 3, and the fiberglass furnace 4 is symmetrically provided with two A burner interface 41, the burner 3 is connected to the glass fiber kiln 4 through the burner interface 41, and can be connected to two groups of pure oxygen combustion systems if necessary; this embodiment also includes a natural gas electric control valve 5, a natural gas flow meter 6, Oxygen electric control valve 7, oxygen flow meter 8, thermocouple 9 and main controller 10; natural gas electric control valve 5 and natural gas flow meter 6 are installed on natural gas pipeline 1; oxygen electric control valve 7, oxygen gas flow meter 6 are installed on oxygen pipeline 2 Flow meter 8; thermocouple 9 is installed on the fiberglass furnace 4 for temperature measurement,...

Embodiment 2

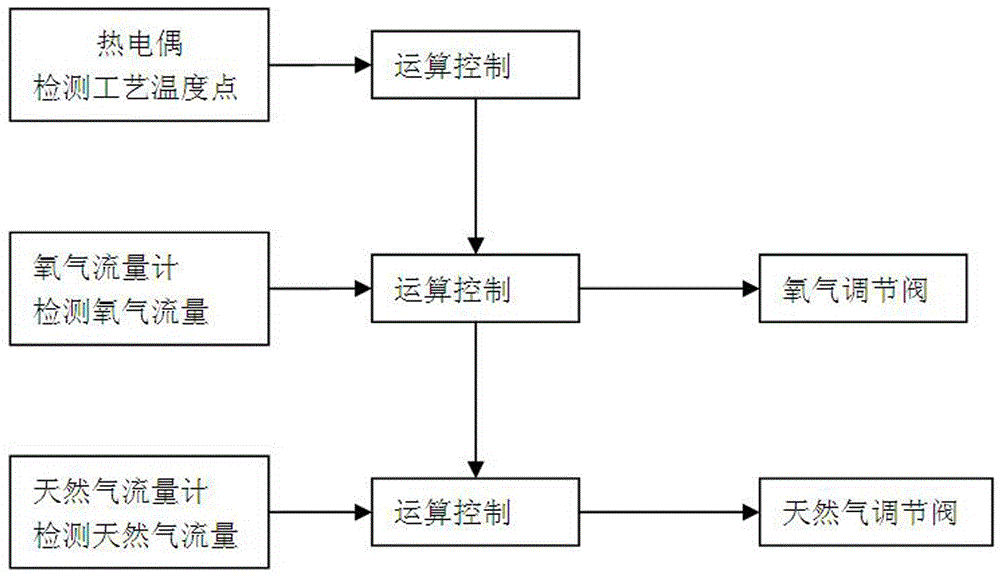

[0036] A control method based on the above-mentioned pure oxygen combustion system of a glass fiber furnace, wherein:

[0037] The thermocouple 9 is installed on the top of the kiln to detect the temperature of the space in the kiln, and as a temperature detection mechanism, the temperature value is sent to the main controller 10;

[0038] The natural gas flow meter 6 and the oxygen flow meter 8 are used as the flow detection mechanism of the system, and the flow value is sent to the main controller 10;

[0039] The natural gas electric regulating valve 5 and the oxygen electric regulating valve 7 are respectively installed on the natural gas pipeline 1 and the oxygen pipeline 2. As the actuators of the system, the main controller 10 controls the opening of the two regulating valves through analog output.

[0040]Constant flow control method: After the glass fiber kiln 4 starts to burn, the actual flow of natural gas and oxygen is displayed on the touch display 101 of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com