Polymer alkali-resisting mortar and production method thereof

A polymer and high molecular polymer technology, applied in the field of building materials, can solve the problems of low base adhesion, low impermeability, poor construction performance, etc., and achieve high adhesion, high impermeability and construction performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

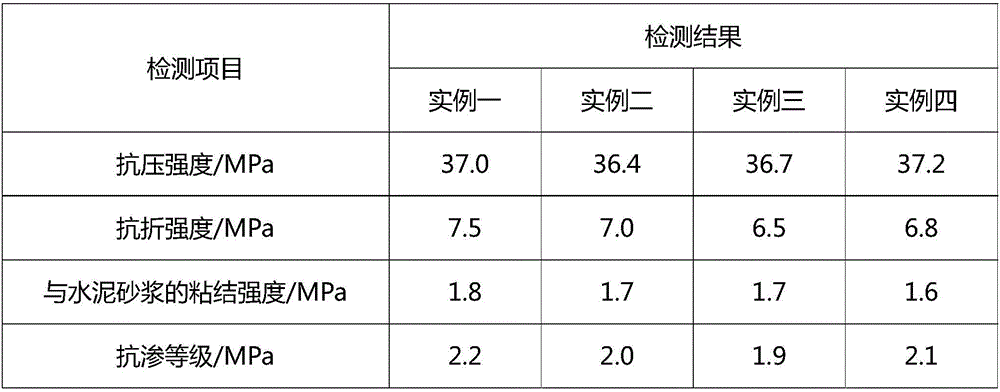

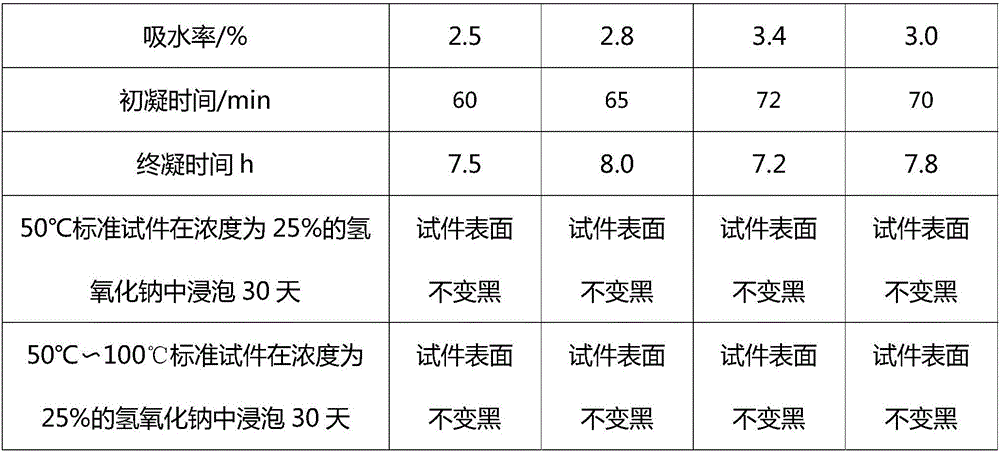

Examples

example 1

[0032] A polymer alkali-resistant mortar and its manufacturing technology. The components and mass parts of this polymer alkali-resistant mortar are as follows: 300 parts of cement, 600 parts of alkali-resistant fine aggregate, 30 parts of compound alkali-resistant compacting agent, 1250 mesh 40 parts of heavy calcium, 15 parts of anti-saponification polymer, 3 parts of high molecular polymer, 5 parts of water reducer, 2 parts of early strength agent, and 2 parts of thixotropic agent. The cement is 52.5-grade Portland cement, the alkali-resistant fine aggregate is limestone or dolomite mechanism sand, the saponification-resistant polymer is imported saponification-resistant redispersible latex powder, and the high molecular polymer It is hydroxypropyl methylcellulose (HPMC), the water reducer is calcium lignosulfonate, the early strength agent is calcium formate, and the thixotropic agent is a special thixotropic agent for imported 602 dry-mixed mortar.

[0033] The manufactur...

example 2

[0042] A polymer alkali-resistant mortar and its manufacturing technology. The components and mass parts of this polymer alkali-resistant mortar are as follows: 290 parts of cement, 610 parts of alkali-resistant fine aggregate, 25 parts of compound alkali-resistant compacting agent, 1250 parts 45 parts of heavy calcium, 15 parts of anti-saponification polymer, 3 parts of high molecular polymer, 5 parts of water reducer, 2 parts of early strength agent, and 2 parts of thixotropic agent. The cement is 52.5-grade Portland cement, the alkali-resistant fine aggregate is limestone or dolomite mechanism sand, the saponification-resistant polymer is imported saponification-resistant redispersible latex powder, and the high molecular polymer It is hydroxypropyl methylcellulose (HPMC), the water reducer is calcium lignosulfonate, the early strength agent is calcium formate, and the thixotropic agent is a special thixotropic agent for imported 602 dry-mixed mortar.

[0043] The manufactu...

example 3

[0046]A polymer alkali-resistant mortar and its manufacturing technology. The components and mass parts of this polymer alkali-resistant mortar are as follows: 310 parts of cement, 590 parts of alkali-resistant fine aggregate, 25 parts of compound alkali-resistant compacting agent, 1250 parts 45 parts of heavy calcium, 15 parts of anti-saponification polymer, 3 parts of high molecular polymer, 5 parts of water reducer, 2 parts of early strength agent, and 2 parts of thixotropic agent. The cement is 52.5 grade Portland cement, the alkali-resistant fine aggregate is limestone or dolomite mechanism sand, the saponification-resistant polymer is imported saponification-resistant redispersible latex powder, and the high molecular polymer It is hydroxypropyl methylcellulose (HPMC), the water reducer is calcium lignosulfonate, the early strength agent is calcium formate, and the thixotropic agent is a special thixotropic agent for imported 602 dry-mixed mortar.

[0047] The manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com