L-tryptophane fermentation process

A fermentation process and tryptophan technology, which is applied in the field of L-tryptophan fermentation process, can solve the problems of excessive accumulation of acetic acid and inhibit fermentation acid production, so as to prolong the acid production cycle, improve the sugar-acid conversion rate and the filtration rate. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A fermentation process for L-tryptophan, the specific steps are as follows:

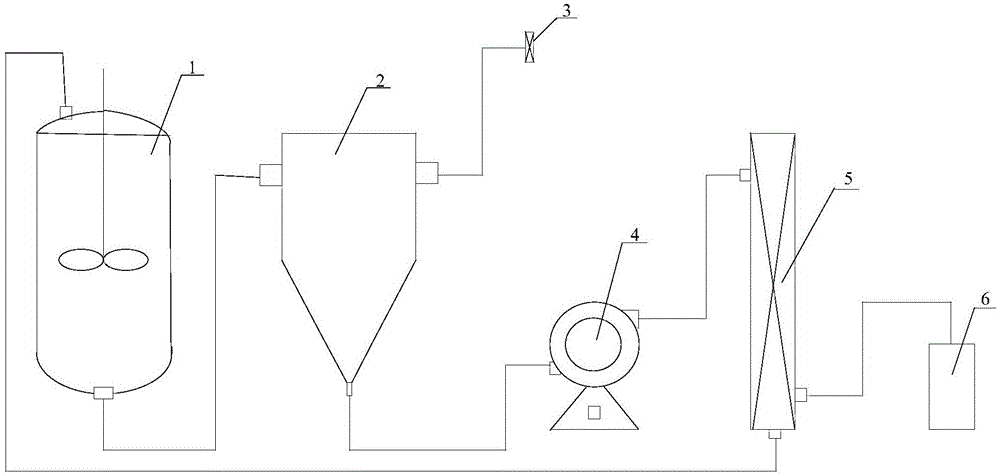

[0034] (1) such as figure 1 As shown, the filter device is assembled. The filter device includes a 30L fermentation tank 1, a gas-liquid separator 2, a variable-speed regulating pump 4, a membrane separation device 5, and a storage tank 6, and the fermentation tank outlet and the gas-liquid separator ( The material inlet of the cyclone gas-liquid separator can be connected, the gas outlet of the gas-liquid separator is connected to the high-temperature air filter membrane 3 through a long pipe, and the bottom of the gas-liquid separator is at an angle of 60° with the horizontal plane. The liquid outlet is located at the bottom of the cone, and the liquid outlet is connected to the membrane separation device through a variable speed regulating pump. The membrane separation device is respectively connected to the storage tank and the fermentation tank, and the membrane separation device is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com