A kind of vancomycin culture medium and the method for preparing vancomycin

A technology of vancomycin and culture medium, applied in the field of drug production, can solve problems such as changing yield and quality, and achieve the effects of enhancing safety and effectiveness, increasing yield, improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

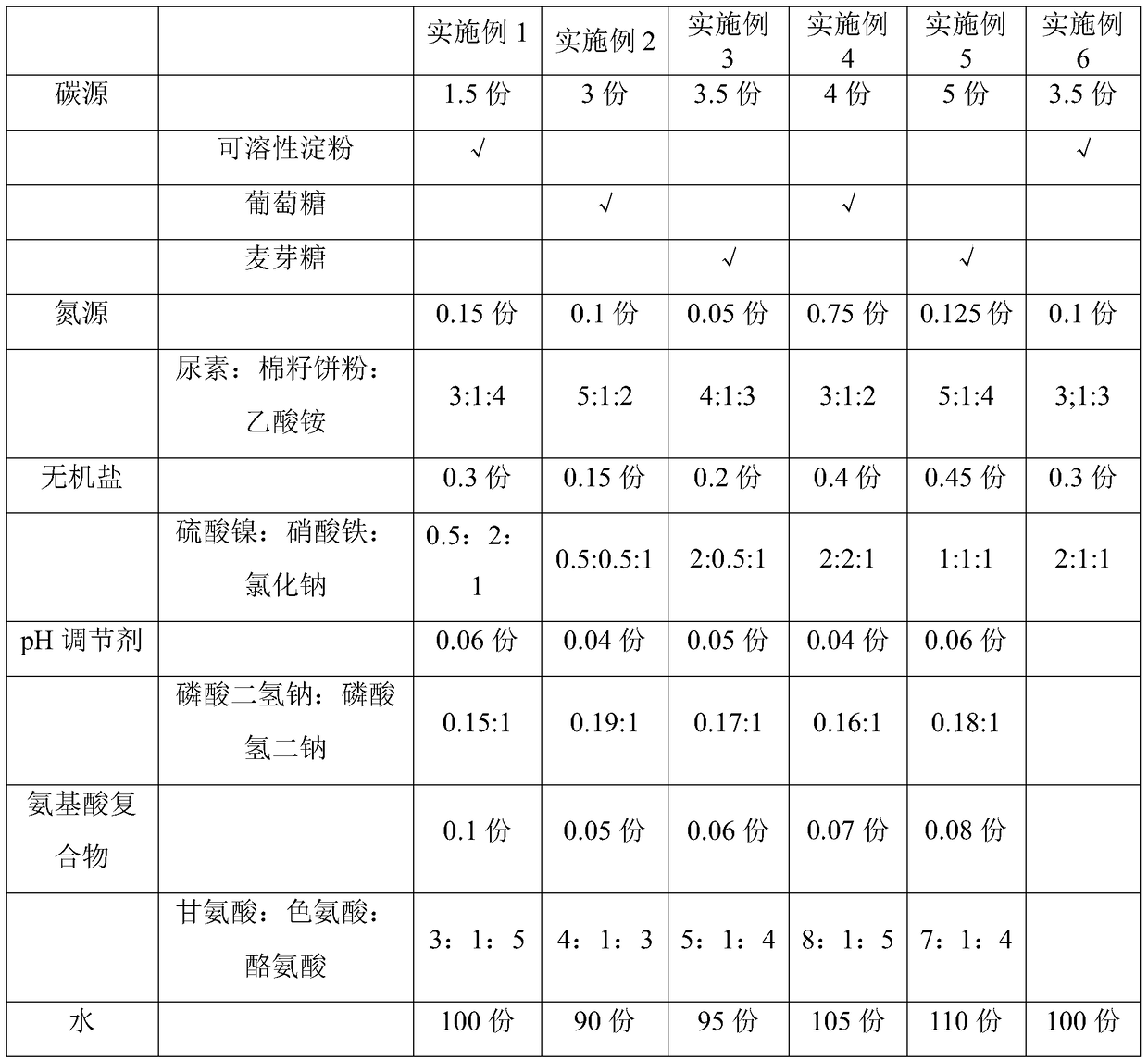

Examples

Embodiment 6

[0039] The difference between the preparation method of the medium in Example 6 and the medium in Examples 1-5 is that no amino acid complex is added in step 2, and no pH regulator is added in step 3 to adjust the pH.

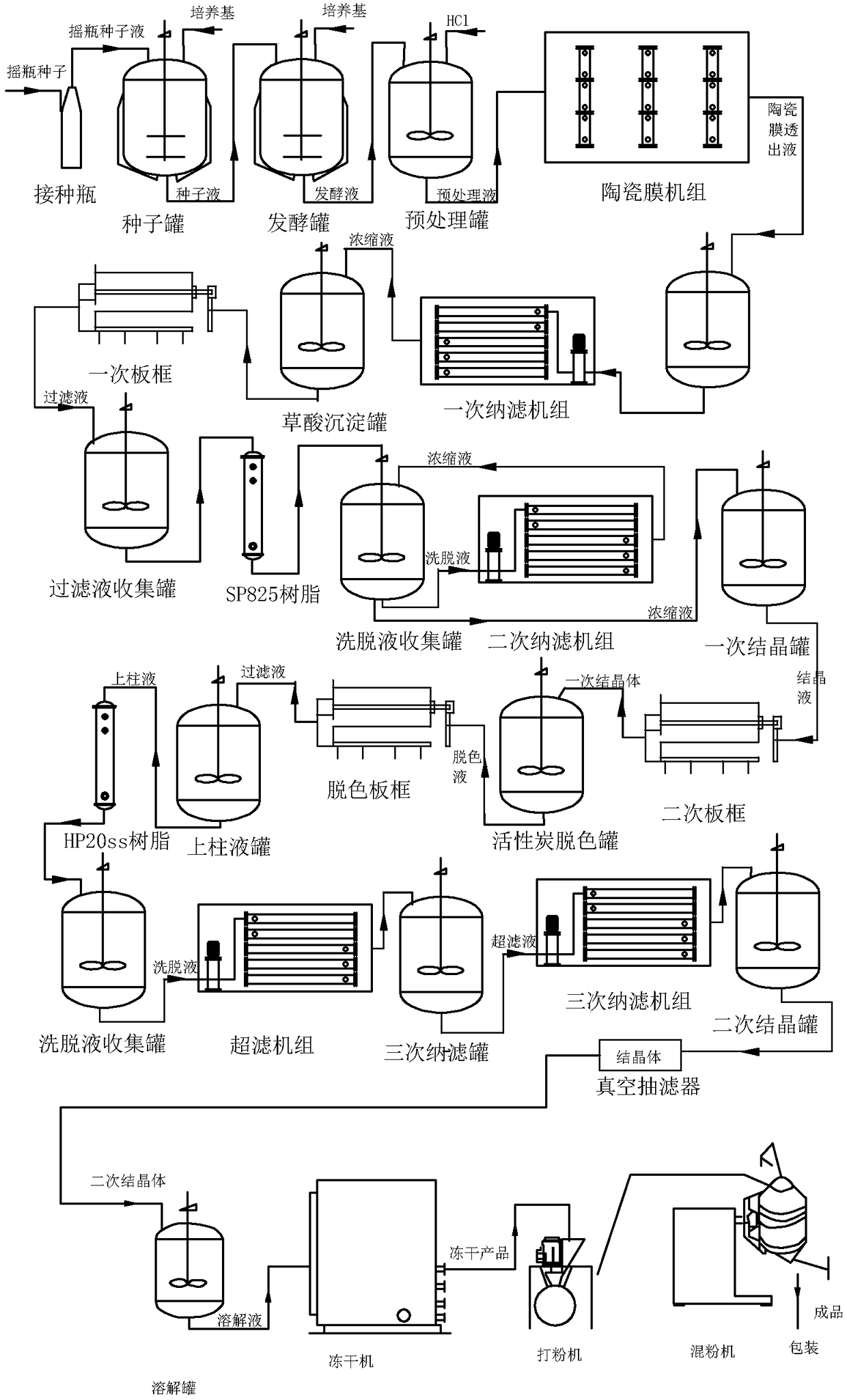

[0040] refer to figure 1 , embodiment 7-9 is the preparation of vancomycin

Embodiment 7

[0042] The medium prepared according to Example 1 was selected for use.

[0043] Step 1: seed inoculation in shake flasks, culture in vancomycin medium in seed tanks, culture in vancomycin medium in fermenters to obtain vancomycin fermentation broth. Place the vancomycin fermentation broth in a pretreatment tank, control the rotation speed to 80 rad / min, and the temperature is 25°C, add 0.1% of the volume of the fermentation broth with hydrochloric acid with a mass fraction of 10% to form a salt, and stir for 30 minutes to obtain a pretreatment liquid .

[0044] Step 2: Filtration with a ceramic membrane. A multi-channel ceramic membrane is selected, the number of channels is 10, the membrane material is silicon dioxide, and the pore size is 0.2 μm. The cross-flow mode is used for circulating filtration, and the pressure is controlled at 0.1MPa.

[0045] Step 3: After filtering through the ceramic membrane, enter the primary nanofiltration unit. The nanofiltration uses an ar...

Embodiment 8

[0064] The difference between embodiment 8 and embodiment 7 is:

[0065] The medium prepared according to Example 2 was selected for use.

[0066] In step 1, hydrochloric acid with a mass fraction of 12% of 0.5% of the volume of the fermented liquid is added for salification; in step 2, ceramic membranes are used for filtration, and multi-channel ceramic membranes are selected, and the number of channels is 8; in steps 3, 7 and 14, The pressure is controlled at 2MPa, the temperature of the filtrate is controlled at 21°C, the flow rate of the nanofiltration is controlled at 320L / h, and the concentration volume multiple of the nanofiltration is 4 times. After the nanofiltration is completed, use purified water for top washing for 8 minutes; After filtration, enter the oxalic acid precipitation tank, and then add 0.002% solid sodium oxalate of the concentrated solution obtained by nanofiltration once, and let it stand after stirring for 30 minutes; in steps 8 and 15, enter the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com