Preparation method of super-strong high-conductivity copper alloy serving as contact line material of high-speed railway with speed per hour being above 400 kilometers

A technology of copper alloy and master alloy, which is applied in the field of Cu alloy preparation, can solve the problems of not being able to meet the minimum requirements of the contact wire material performance, and achieve the effect of preventing the spheroidization trend, reducing the scattering effect, and improving the overall strength level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

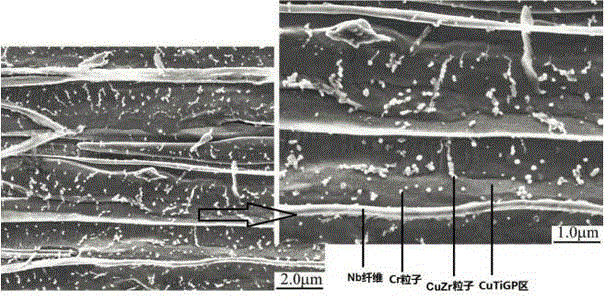

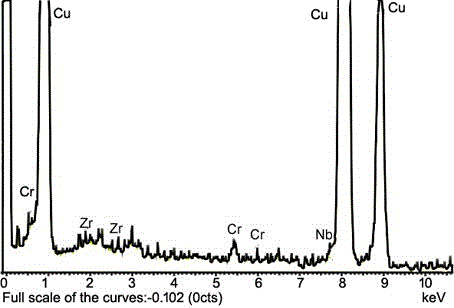

[0032] Using pure copper, Cu-25%Nb master alloy, Cu-13%Cr master alloy, Cu-7%Zr master alloy and Cu-10%Ti master alloy as raw materials, it is melted in a vacuum induction melting furnace and quickly cast on water-cooled copper In the mold, the cooling rate is 30°C / s to obtain a Cu-3%Nb-1%Cr-0.5%Zr-0.2%Ti ingot. The ingot was drawn for multiple passes at room temperature, with a single drawing deformation of 0.15, and finally reached a drawing deformation of 5.5. The drawn and deformed copper alloy rod or wire was annealed at 375 °C for 100 h. The annealed copper alloy was drawn again at room temperature, and the drawing deformation was 0.5. The above copper alloy was frozen in liquid nitrogen for 72 h, and then slowly warmed to room temperature at a rate of 5 °C / min. The standard tensile test was used to test the tensile strength of the alloy, and the standard four-point method was used to test the room temperature conductivity of the alloy. The alloy was softened by anneal...

Embodiment 2

[0034] Using pure copper, Cu-10%Nb master alloy, Cu-5%Cr master alloy, Cu-5%Zr master alloy and Cu-3%Ti master alloy as raw materials, it is melted in a vacuum induction melting furnace and quickly cast on water-cooled copper In the mold, the cooling rate was 50°C / s to obtain a Cu-10%Nb-0.5%Cr-0.3%Zr-0.1%Ti ingot. The ingot was drawn for multiple passes at room temperature, with a single drawing deformation of 0.1 and a final drawing deformation of 6.0. Anneal the drawn and deformed copper alloy rod or wire at 450°C for 10 h. The annealed copper alloy was drawn again at room temperature, and the drawing deformation was 0.5. The above copper alloy was frozen in liquid nitrogen for 48 h, and then slowly warmed up to room temperature at a rate of 2 °C / min. The standard tensile test was used to test the tensile strength of the alloy, and the standard four-point method was used to test the room temperature conductivity of the alloy. The alloy was softened by annealing at 400 °C f...

Embodiment 3

[0036]Using pure copper, Cu-20%Nb master alloy, Cu-10%Cr master alloy, Cu-6%Zr master alloy and Cu-5%Ti master alloy as raw materials, it is melted in a vacuum induction melting furnace and quickly cast on water-cooled copper In the mold, the cooling rate was 100°C / s to obtain a Cu-20%Nb-0.1%Cr-0.1%Zr-0.05%Ti ingot. The ingot was drawn for multiple passes at room temperature, with a single drawing deformation of 0.2, and finally reached 4 drawing deformations. Anneal the drawn and deformed copper alloy rod or wire at 575°C for 1 h. The annealed copper alloy was drawn again at room temperature, and the drawing deformation was 0.5. The above copper alloy was frozen in liquid nitrogen for 12 h, and then slowly warmed to room temperature at a rate of 8 °C / min. The standard tensile test was used to test the tensile strength of the alloy, and the standard four-point method was used to test the room temperature conductivity of the alloy. The alloy was softened by annealing at 400 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com