Easy decontamination finishing agent and its preparation method and application

A technology for easy decontamination finishing and dispersing agent, which can be used in the processing of textile material equipment configuration, fiber processing, textiles and papermaking, etc., can solve the problems of high extraction cost, increased greasiness of rags, and large amount of cellulase used. The effect of improving the performance of easy decontamination, improving the viscosity, and improving the bacteria resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

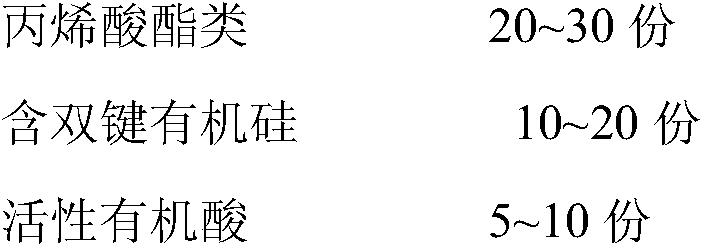

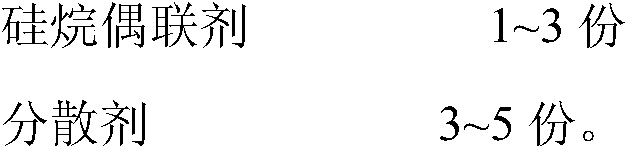

Method used

Image

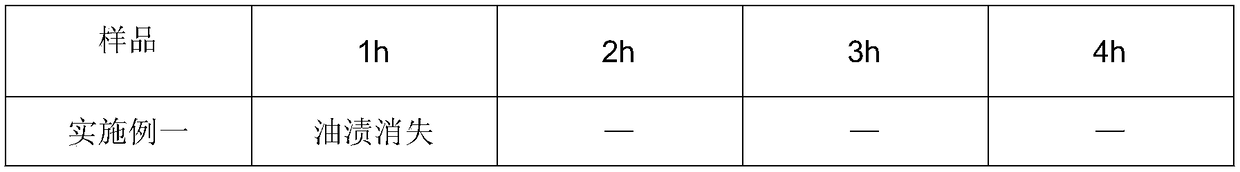

Examples

Embodiment 1

[0041] (1) Add 2 parts of malic acid, 3 parts of caffeic acid and 20 parts of methyl acrylate to the three-necked flask in turn, heat to 60°C in an oil bath while stirring, and the stirring speed is 70r / min;

[0042] (2) Add 10 parts of vinyltrimethoxysilane into the three-necked flask, the stirring speed is 100r / min, and the stirring time is 30min;

[0043] (3) Add 0.5 parts of γ-aminopropyltriethoxysilane and 0.5 parts of aminotrimethoxysilane to the three-necked flask;

[0044] (4) Slowly add 3 parts of triethylhexyl phosphoric acid into the three-necked flask, control the flow rate of the separatory funnel to 1 part / min, and react for 2 hours.

Embodiment 2

[0046] (1) Add 4 parts of malic acid, 4 parts of caffeic acid and 25 parts of ethyl acrylate to the three-necked flask successively, heat to 65°C in an oil bath while stirring, and the stirring speed is 75r / min;

[0047] (2) Add 10 parts of propenyltrimethoxysilane into the three-necked flask, stir at a stirring speed of 110r / min, and stir for 30min;

[0048] (3) Add 0.6 parts of γ-aminopropyltriethoxysilane and 0.9 parts of aminotrimethoxysilane to the three-necked flask;

[0049] (4) Slowly add 4 parts of methyl pentanol into the three-necked flask, control the flow rate of the separatory funnel to 1 part / min, and react for 3 hours.

Embodiment 3

[0051] (1) Add 6 parts of malic acid, 4 parts of caffeic acid and 30 parts of hydroxyethyl methacrylate into the three-necked flask in turn, heat to 70°C in an oil bath while stirring, and the stirring speed is 80r / min;

[0052] (2) Add 20 parts of γ-methylacrylophthaleinoxytrimethoxysilane into the three-necked flask, the stirring speed is 120r / min, and the stirring time is 30min;

[0053] (3) Add 1 part of γ-aminopropyltriethoxysilane and 1 part of aminotrimethoxysilane to the three-necked flask;

[0054] (4) Slowly add 5 parts of triethylhexyl phosphoric acid into the three-necked flask, control the flow rate of the separatory funnel to 1 part / min, and react for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com