Well completion method with reservoir protection and packing functions

A reservoir and functional technology, applied in the field of completion methods with the function of protecting reservoir isolation, can solve problems such as pressure penetration, exceeding the reservoir, and many processes, so as to improve the absorption capacity and seepage capacity, and protect the isolation function , high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

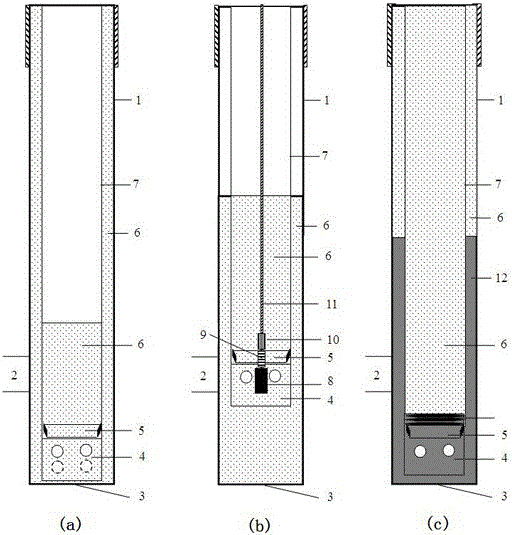

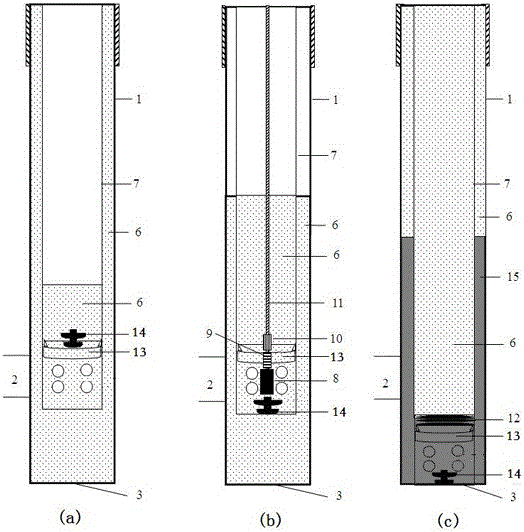

Embodiment 1

[0044] A well completion method with the function of protecting reservoir isolation. When the reservoir 2 is in an open-hole state, at least one high-energy gas fracturing is performed on at least one layer of the reservoir 2 until the reservoir is cemented. 2 Formation of artificial fractures near the wellbore, including the following steps:

[0045] Step 1: Drilling: drilling through layer reservoir 2 to the full drilling depth;

[0046] Step 2: Perforating: establish a tunnel at a predetermined depth in the near-wellbore zone of reservoir 2;

[0047] Step 3: Block building: establish the design liquid block in the wellbore 1, calculate and determine the high-energy gas fracturing parameters according to the liquid block involved;

[0048] Step 4: high-energy gas fracturing: perform at least one high-energy gas fracturing on at least one layer of reservoir 2, and form artificial fractures in the zone near the wellbore 2;

[0049] Step 5: Cementing: Forming a cement sheath ...

Embodiment 2

[0055] A well completion method with the function of protecting the reservoir isolation, drilling through the reservoir 2 without drilling to the completion depth, when the reservoir 2 is in an open hole state, performing at least one high-energy gas fracturing on at least one layer of the reservoir 2, Forming artificial fractures in the zone near the wellbore of reservoir 2 includes the following steps:

[0056] Step 1: drilling: drilling through the reservoir 2 without drilling to the full drilling depth;

[0057] Step 2: Perforating: establish a certain-depth tunnel in the near-wellbore area of reservoir 2;

[0058] Step 3: Block building: establish the design liquid block in the wellbore 1, calculate and determine the high-energy gas fracturing parameters according to the liquid block involved;

[0059] Step 4: high-energy gas fracturing: perform at least one high-energy gas fracturing on at least one layer of reservoir 2, and form artificial fractures in the zone near ...

Embodiment 3

[0067] A well completion method with the function of protecting the reservoir isolation. The reservoir 2 is drilled but not penetrated. At least one high-energy gas fracturing to form artificial fractures in the zone near the wellbore of reservoir 2, including the following steps:

[0068] Step 1: drilling: drilling the reservoir 2 without drilling through the reservoir 2;

[0069] Step 2: Perforating: establish a tunnel at a predetermined depth in the near-wellbore zone of reservoir 2;

[0070] Step 3: Block building: establish the design liquid block in the wellbore 1, calculate and determine the high-energy gas fracturing parameters according to the liquid block involved;

[0071] Step 4: high-energy gas fracturing: perform at least one high-energy gas fracturing on the drilled but not penetrated reservoir 2, and form artificial fractures in the zone near the wellbore of the reservoir 2;

[0072] Step 5: Continue drilling to the full drilling depth;

[0073] Step 6: ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com