Flexible radiation protection material with functions of radiation warning and temperature adjustment and preparation method of flexible radiation protection material

A technology for temperature regulation and radiation protection, applied in protective clothing, reactors, clothing, etc., can solve the problems of airtightness, poor wearing comfort, and biological toxicity, and achieve the effects of reducing body temperature, increasing comfort, and no biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

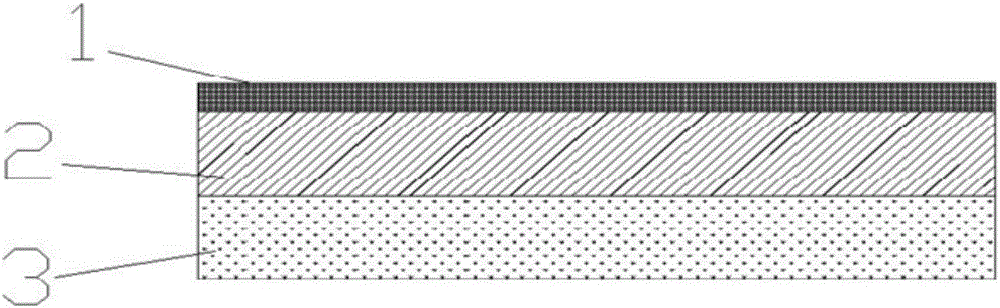

[0032] The preparation method of the flexible radiation protection material with radiation warning and temperature adjustment functions of the present invention comprises the following steps:

[0033] (1) Add room temperature vulcanized silicone liquid, additives and phase change energy storage capsule materials into a vacuum defoaming mixer and stir for 5-10 minutes, then use a silicone sprayer to evenly spray the stirred silicone mixture on the release cloth, blow 150~170℃ hot air, after 0.5~1h, curing and molding to obtain the temperature regulation layer;

[0034] (2) Add room temperature vulcanized silica gel liquid, additives and metal and oxide powder materials that absorb γ / X rays into a vacuum defoaming mixer and stir for 5-10 minutes, and then use a silica gel sprayer to evenly spray the stirred silica gel mixture on the Blow hot air at 150-170°C on the formed temperature-regulating layer, and after 0.5-1 hour, solidify and form to obtain a radiation shielding layer;...

Embodiment 1

[0039] The formula of the flexible radiation protection material with radiation warning and temperature adjustment functions is as follows: temperature adjustment layer, 60g of room temperature vulcanized silica gel, 20g of phase change energy storage capsule particle material coated with polyurethane wax, 5g of additives; radiation shielding layer, 10g of room temperature vulcanized silica gel , 25g of tungsten powder, 60g of bismuth oxide powder, 5g of additives; radiation warning layer, 35g of room temperature vulcanized silica gel, 55g of zinc sulfide mixed with silver phosphor, 5g of additives. Among them, the particle size of the polyurethane-coated paraffin phase-change energy storage capsule material is 1um, the particle size of the tungsten powder is 2um, the particle size of the bismuth oxide powder is 2um, and the particle size of the zinc sulfide mixed with silver powder is 20um.

[0040] The steps of the preparation method of the flexible radiation protection mater...

Embodiment 2

[0046] The formula of the flexible radiation protection material with radiation warning and temperature adjustment functions is: temperature adjustment layer, 70g of room temperature vulcanized silica gel, 15g of phase change energy storage capsule particle material coated with polyurethane wax, 7g of additives; shielding layer, 18g of room temperature vulcanized silica gel, Tungsten powder 10g, bismuth oxide powder 60g, additive 7g; radiation warning layer, room temperature vulcanized silica gel 50g, zinc sulfide doped with silver phosphor 40g, additive 7g. Among them, the particle size of the polyurethane-coated paraffin phase-change energy storage capsule material is 5um, the particle size of the tungsten powder is 5um, the particle size of the bismuth oxide powder is 6um, and the particle size of the zinc sulfide mixed with silver powder is 35um.

[0047] The steps of the preparation method of the flexible radiation protection material with radiation warning and temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com