P-channel schottky gate silicon carbide electrostatic induction thyristor and manufacturing method thereof

A technology of Schottky gate and electrostatic induction, which is applied in the direction of thyristor, semiconductor/solid-state device manufacturing, circuit, etc., can solve the problems of increasing the complexity of the driving circuit, limited application value, increasing the driving power, etc., and achieves the reduction of gate switching characteristics , reduce impedance, reduce the effect of process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

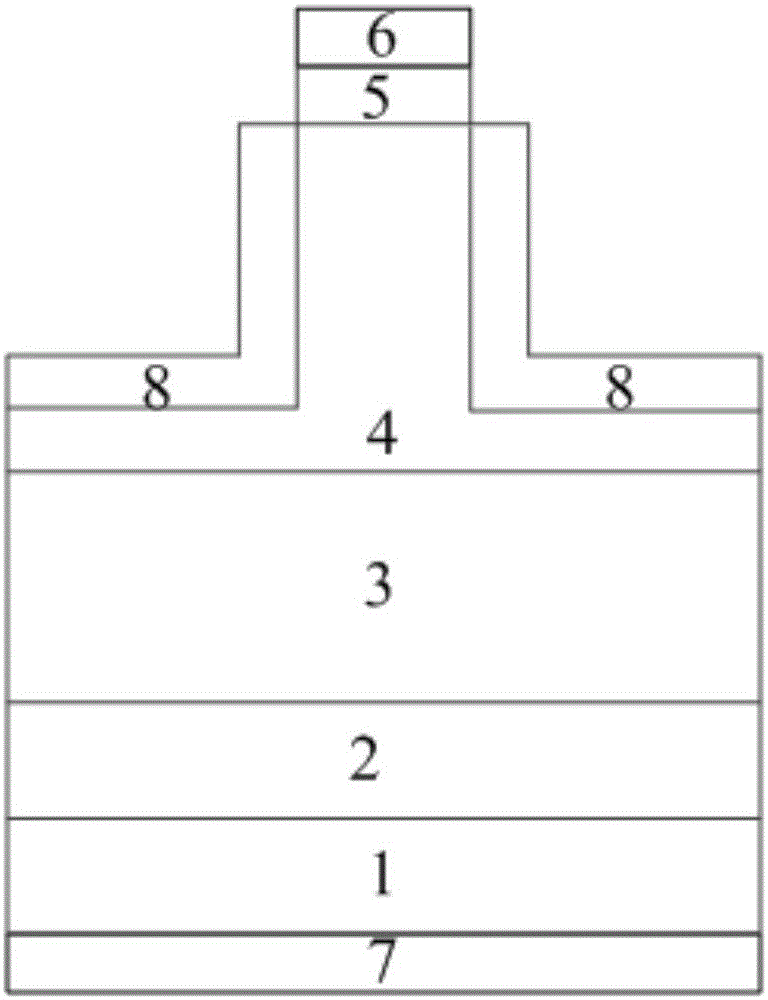

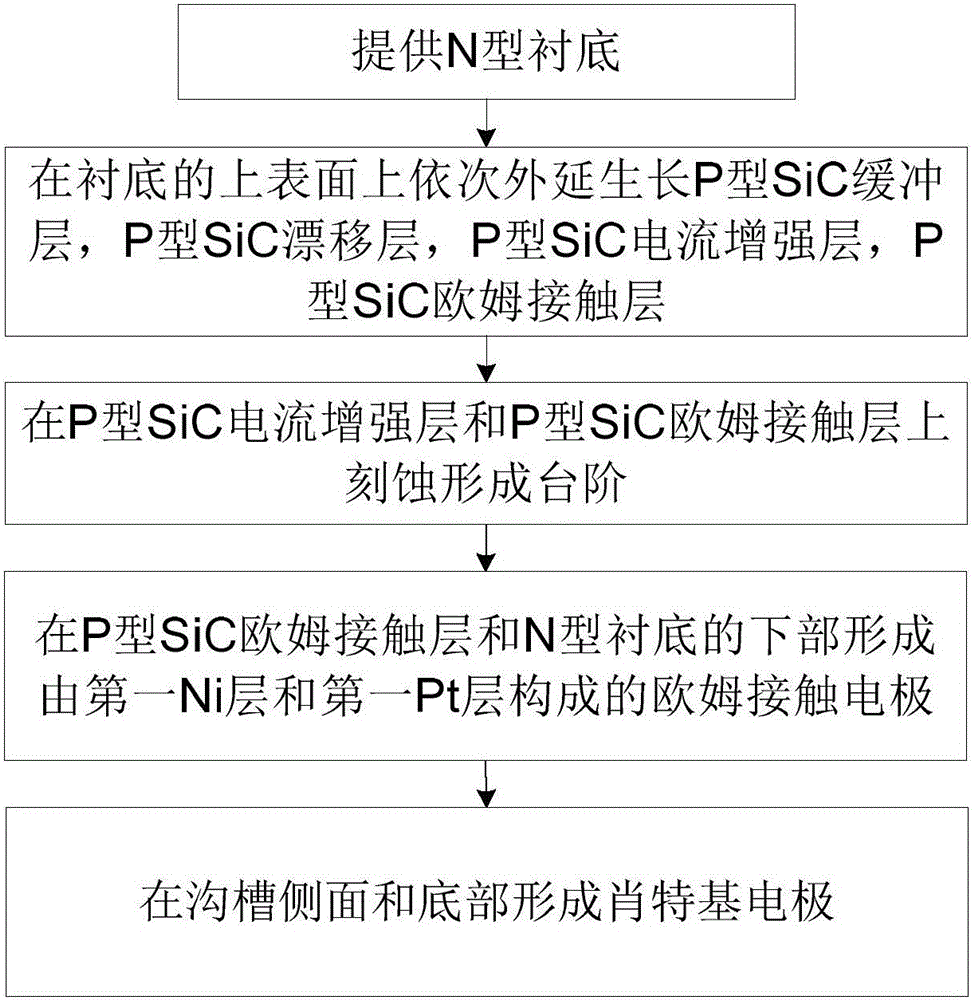

[0037] see figure 1 , the structure of the present invention comprises an N-type SiC substrate 1 and a P-type SiC buffer layer 2 arranged on the top of the N-type SiC substrate, a P-type SiC drift layer 3 is arranged on the P-type SiC buffer layer 2, and the P-type SiC drift layer 3 is provided with a P-type SiC current enhancement layer 4, a P-type SiC ohmic contact layer 5 is provided on the P-type SiC current enhancement layer 4, and a plurality of steps are formed by etching on the P-type current enhancement layer 4 and the P-type SiC ohmic contact layer 5, Grooves are arranged between adjacent steps, Schottky electrodes 8 are arranged on the sides of the steps and at the bottom of the grooves, and a P-type electrode having the same shape as the P-type SiC ohmic contact layer 5 is arranged on the upper part of the P-type SiC ohmic contact layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com