Soil fertilization method by directly returning straw to filed

A technology of straw and soil, which is applied in the direction of soil preparation, organic fertilizer, agricultural machinery and implements, etc., can solve problems such as aggravation of diseases and insect pests, difficulty in sowing, weak growth of seedlings, etc., to increase soil organic matter content, improve land production capacity, and accelerate decomposition conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

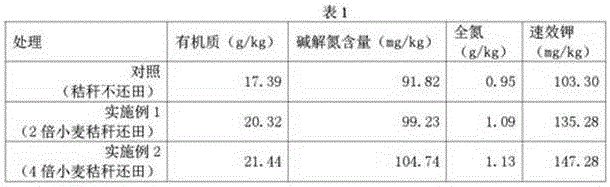

Examples

Embodiment 1

[0026] A specific operation step for directly returning straw to the field to fertilize the soil is as follows:

[0027] (1) During the wheat harvest season, use a harvester to harvest wheat, leave low stubble, and collect wheat straw;

[0028] (2) The amount of wheat straw returned to the field is 1000 kg / mu, and the wheat straw is disposed of on 1 / 2 mu of cultivated land, that is, the wheat straw is evenly spread on 1 / 2 mu of cultivated land, and the Lovol 1204 tractor with a rotary tiller is used Carry out rotary tillage, and perform the rotary tillage operation twice, and the rotary tillage time is June 10, 2015, so that the wheat straw can be fully mixed with the soil;

[0029] (3) One month later, the second rotary tillage will be carried out on July 10, 2015;

[0030] (4) Let the arable land fallow after the second rotary tillage go through a corn growing season, that is, from June 10, 2015 to October 8, 2015, the straw will be fully decomposed in the soil and transfor...

Embodiment 2

[0033] Location: Madian Experimental Station of Provincial Academy of Agricultural Sciences, Mengcheng County, Anhui Province. Soil for test: Shajiang black soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com