Preparation method of water-soluble biological organic fertilizer

A bio-organic fertilizer and water-soluble technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve problems such as shortages, and achieve the effects of increasing nutrient content, accelerating decomposition and transformation, and reducing ammonia odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

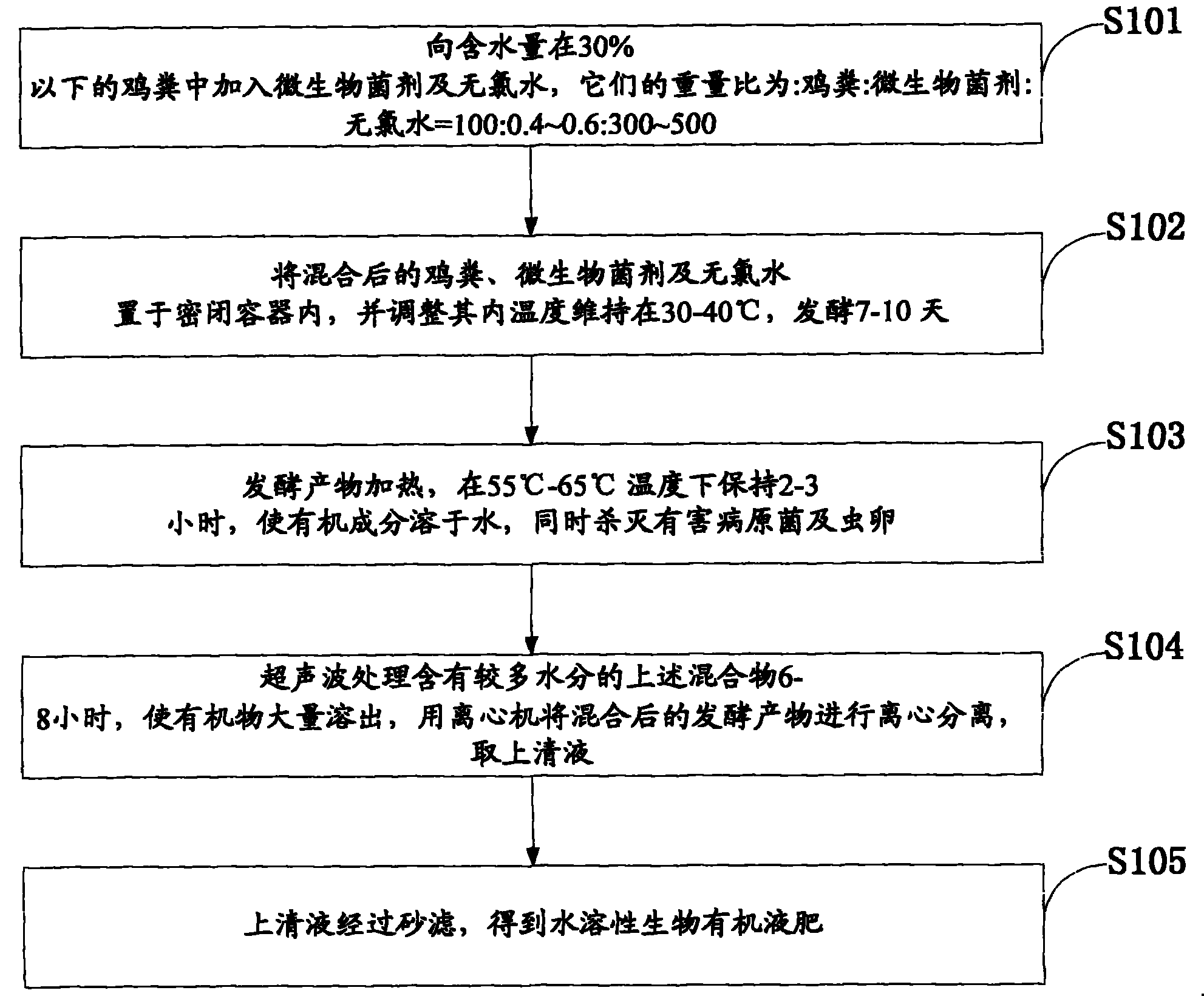

[0024] The preparation method of the water-soluble biological organic fertilizer of the embodiment of the present invention, the preparation method of this water-soluble biological organic fertilizer comprises the following steps:

[0025] Step 1, adding microbial agent and chlorine-free water to chicken manure, the weight ratio is: chicken manure: microbial agent: chlorine-free water=100:0.4~0.6:300~500;

[0026] Step 2, placing the mixed chicken manure, microbial agent and chlorine-free water in a closed container, and adjusting the internal temperature to maintain at 30-40°C, and fermenting for 7-10 days;

[0027] Step 3, heating the fermentation product to dissolve the organic components in water and kill harmful pathogenic bacteria and insect eggs at the same time;

[0028] Step 4, ultrasonically treating the mixed fermentation product for 6-8 hours to dissolve a large amount of organic matter, centrifuging the mixed fermentation product with a centrifuge, and taking the ...

Embodiment 1

[0053] Take 1000kg of fresh chicken manure with a water content less than 30% in a chicken farm in the suburbs of Nanjing City, Jiangsu Province, add 4000kg of water and 4kg of EM microbial bacterial agent produced by Aimule Environmental Biotechnology (Nanjing) Co., Ltd., stir well, and place it outside Set the jacketed storage tank, then close the opening, adjust the water temperature in the jacket, keep the temperature in the tank at 35-40°C, ferment for 7 days, heat the above fermentation product, and maintain the temperature at 60-65°C for 2 hours , ultrasonic treatment of the above mixture containing more water for 6 hours to dissolve a large amount of organic matter, centrifuge the above mixture with a centrifuge, take the supernatant, and filter the supernatant through sand to obtain 3000-3500kg of yellowish-brown liquid. bottle.

Embodiment 2

[0055] Take 1000kg of fresh chicken manure with a water content less than 30% in a chicken farm in the suburbs of Nanjing City, Jiangsu Province, add 5000kg of water and 5kg of EM microbial bacterial agent produced by Aimule Environmental Biotechnology (Nanjing) Co., Ltd., stir thoroughly, and place outside Set the jacketed storage tank, then close the opening, adjust the water temperature in the jacket, keep the temperature in the tank at 30-35°C, ferment for 10 days, heat the above-mentioned fermentation product, and maintain the temperature at 55-60°C for 3 Hours, ultrasonically treat the above-mentioned mixture containing more water for 8 hours to dissolve a large amount of organic matter, centrifuge the above-mentioned mixture with a centrifuge, take the supernatant, and filter the supernatant through sand to obtain 4000-4500kg of yellow-brown liquid , bottling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com