Preparation process of squeezed apple juice

A preparation process and a technology for freshly squeezed juice, which are applied in the field of preparation of freshly squeezed fruit juice of apples that are prone to browning, can solve the problems of restraining the degree of browning and the limited effect, and achieve the advantages of maintaining flavor and nutrition, fast cooling speed and accelerating cooling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Choose fresh and ripe Red Fuji apples, free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 10Brix;

[0025] (2) Cleaning: put the apples in step (1) into the bubbling washing machine, and fully clean the apples by bubbling, stirring, etc.;

[0026] (3) Petal cutting: use a petal cutting machine to cut the apple into 4 petals;

[0027] (4) Coupling of crushing and killing enzymes: select the steam pressure as 0.12MPa, first pass the steam for 2 minutes to drive away the oxygen in the equipment, feed the screw quantitatively, pass the steam to heat while crushing, and the slurry will be heated to 80°C within 3 minutes. Keep for 48s and discharge;

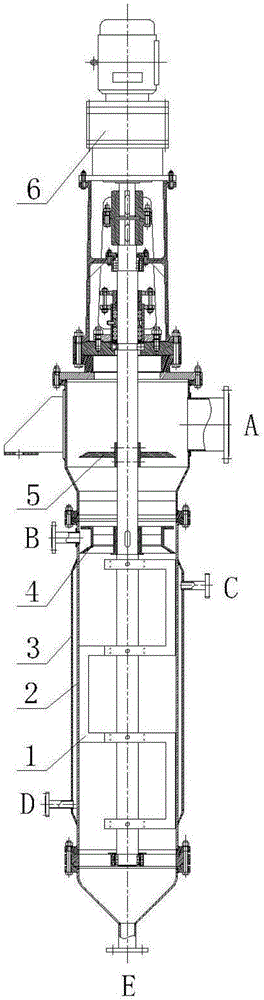

[0028] (5) ultra-fast cooling: the apple slurry described in step (4) is quickly entered in the vacuum cooler, the vacuum degree is 0.096MPa, the temperature of the frozen brine in the jacket is-6°C, and the material descends in a film shape, Part of the water evaporates, and the t...

Embodiment 2

[0034] (1) Choose fresh and ripe Red Fuji apples, free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 10Brix;

[0035] (2) Cleaning: put the apples in step (1) into the bubbling washing machine, and fully clean the apples by bubbling, stirring, etc.;

[0036] (3) Cutting the petals: use a petaling machine to cut the apples into 6 petals;

[0037] (4) Coupling of crushing and killing enzymes: select the steam pressure as 0.18MPa, first pass the steam for 3 minutes to drive away the oxygen in the equipment, feed the screw quantitatively, pass the steam to heat while crushing, and the slurry will be heated to 85°C within 2 minutes. After keeping for 33s, discharge;

[0038] (5) ultra-fast cooling: the apple slurry described in step (4) is quickly entered in the vacuum cooler, the vacuum is 0.085MPa, the temperature of the frozen brine in the jacket is-5°C, and the material descends in a film shape, Part of the water evaporates, and the t...

Embodiment 3

[0046] (1) Choose fresh and ripe Red Fuji apples, free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 10Brix;

[0047] (2) Cleaning: put the apples in step (1) into the bubbling washing machine, and fully clean the apples by bubbling, stirring, etc.;

[0048] (3) Petal cutting: use a petal cutting machine to cut the apple into 8 petals;

[0049] (4) Coupling of crushing and killing enzymes: select the steam pressure as 0.22MPa, first pass the steam for 2 minutes to drive away the oxygen in the equipment, feed the screw quantitatively, pass the steam to heat while crushing, and the slurry will heat up to 92°C within 1 minute. Keep it for 12s and discharge it;

[0050] (5) Ultra-fast cooling: the apple slurry described in step (4) is quickly put into the vacuum cooler, the vacuum degree is 0.092MPa, the temperature of the frozen brine in the jacket is -4°C, and the material descends in a film shape, and a part The water evaporates, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com