Methane control method for household garbage quasi-aerobic landfill

A control method and domestic waste technology, applied in methane capture, solid waste removal, greenhouse gas capture, etc., can solve problems such as high operation and management costs, large power consumption, complex processes and equipment, etc., to achieve fast waste decomposition, Accelerate the stabilization of garbage and the effect of fast stabilization of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

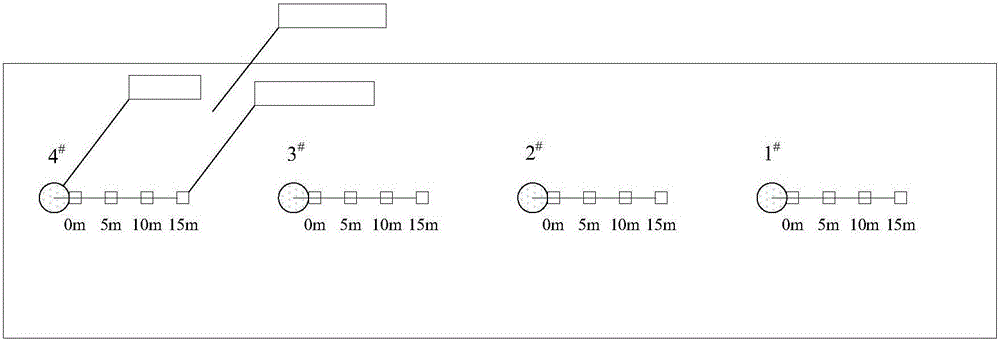

[0038] The experimental sampling site is Zhuozhou quasi-aerobic landfill in Hebei Province.

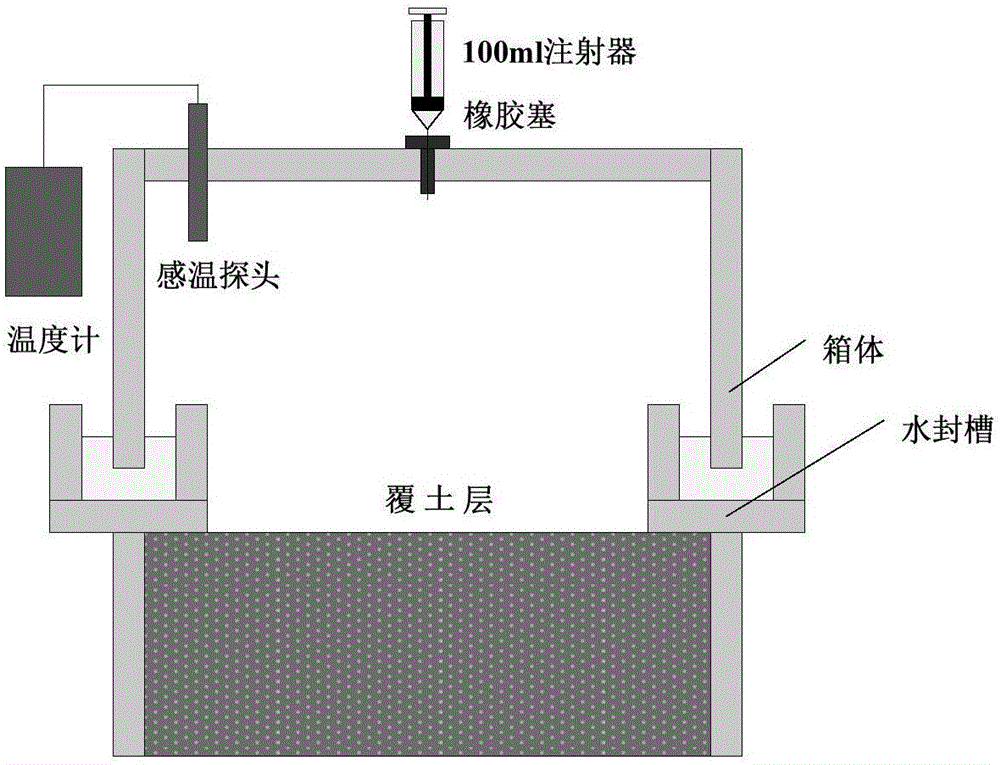

[0039] The basic construction method of the quasi-aerobic landfill is as follows: a compacted clay liner with a thickness of 20-30 cm is laid on the flat and compacted foundation soil, and a high-density polyethylene (HDPE) film is laid on it. Geotextiles are respectively laid on the HDPE membrane, and a leachate drainage layer with a thickness of 50-60 cm is laid on the geotextiles, in which the leachate drainage pipe is buried. The end of the leachate drainage pipe is connected to the atmosphere, so that the leachate produced can be discharged in time, and the outside air can freely enter the landfill. The leachate drainage pipe is protected by a gabion. The leachate drainage pipe is connected with the vertical perforated airway with openings. The hole diameters of the vertical perforated airway are 12-16 mm, and the hole distance is 6-10 cm. The vertical perforated airway is used ...

Embodiment 2

[0059] Using the experimental method in Example 1, an intermediate covering layer is respectively laid on the working surface of each experimental landfill area. The intermediate covering layer adopts a mixture of mineralized waste: new covering soil weight ratio of 1:10, and its parameters are changed. Each intermediate The covering layer is laid 25m×25m. Study the specific parameters of the intermediate overburden and the CH on the surface of the landfill area 4 The relationship between gas fluxes.

[0060] Among them, the specific parameters of the middle covering layer are shown in Table 2; the test results are shown in Table 3.

[0061] Table 2: Intermediate Overlay Parameters

[0062]

[0063] Table 3: CH on the surface of the landfill 4 Comparison of gas flux detection results

[0064]

[0065]

[0066]The above studies show that the thickness of the intermediate covering layer directly affects the flux of methane gas released from the surface of the landfi...

Embodiment 3

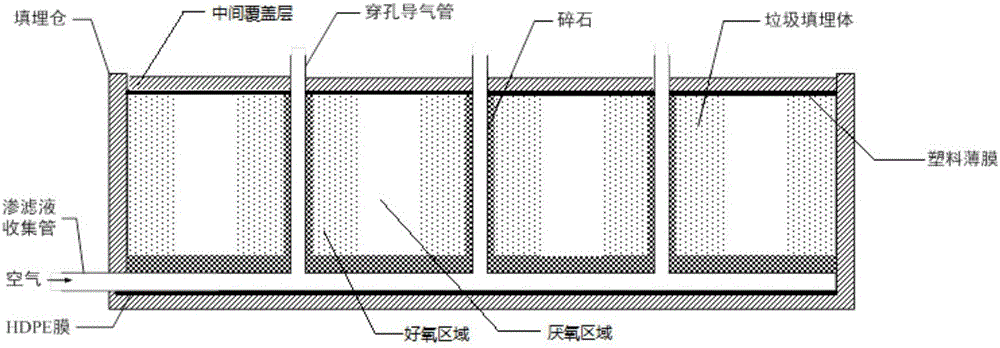

[0070] Using the quasi-aerobic landfill of domestic waste in Example 1, the landfill units are buried successively along the horizontal direction to form a landfill layer, and the surface of each layer of landfill layer is covered with an intermediate covering layer, and the intermediate covering layer is new The mixture of covering soil and mineralized waste with a weight ratio of 10:1, the particle size of mineralized waste is 3-10mm, and the particle size of new covering soil is 0.02-0.2mm. Its structural diagram is as image 3 shown.

[0071] Among them, 10 experimental areas were set up in the landfill, and the parameters of the vertical air ducts and gabions in each experimental area are shown in Table 4:

[0072] Table 4: Parameters of vertical air ducts and gabions

[0073]

[0074]

[0075] The methane gas in the air duct is detected by setting a gas collection device in the vertical perforated air duct. The concentration detection in the air duct uses a four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com