Method and device for vertical measurement and correction of molybdenum wire for CNC wire cutting machine

A technology of wire cutting machine and vertical measurement, which is applied in the direction of auxiliary equipment, electric processing equipment, electrode manufacturing, etc., can solve the problems of not fully representing the actual operation of the equipment, large errors in visual inspection methods, and strong dependence, etc., to achieve wire cutting Vertical automatic correction, avoiding measurement errors, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

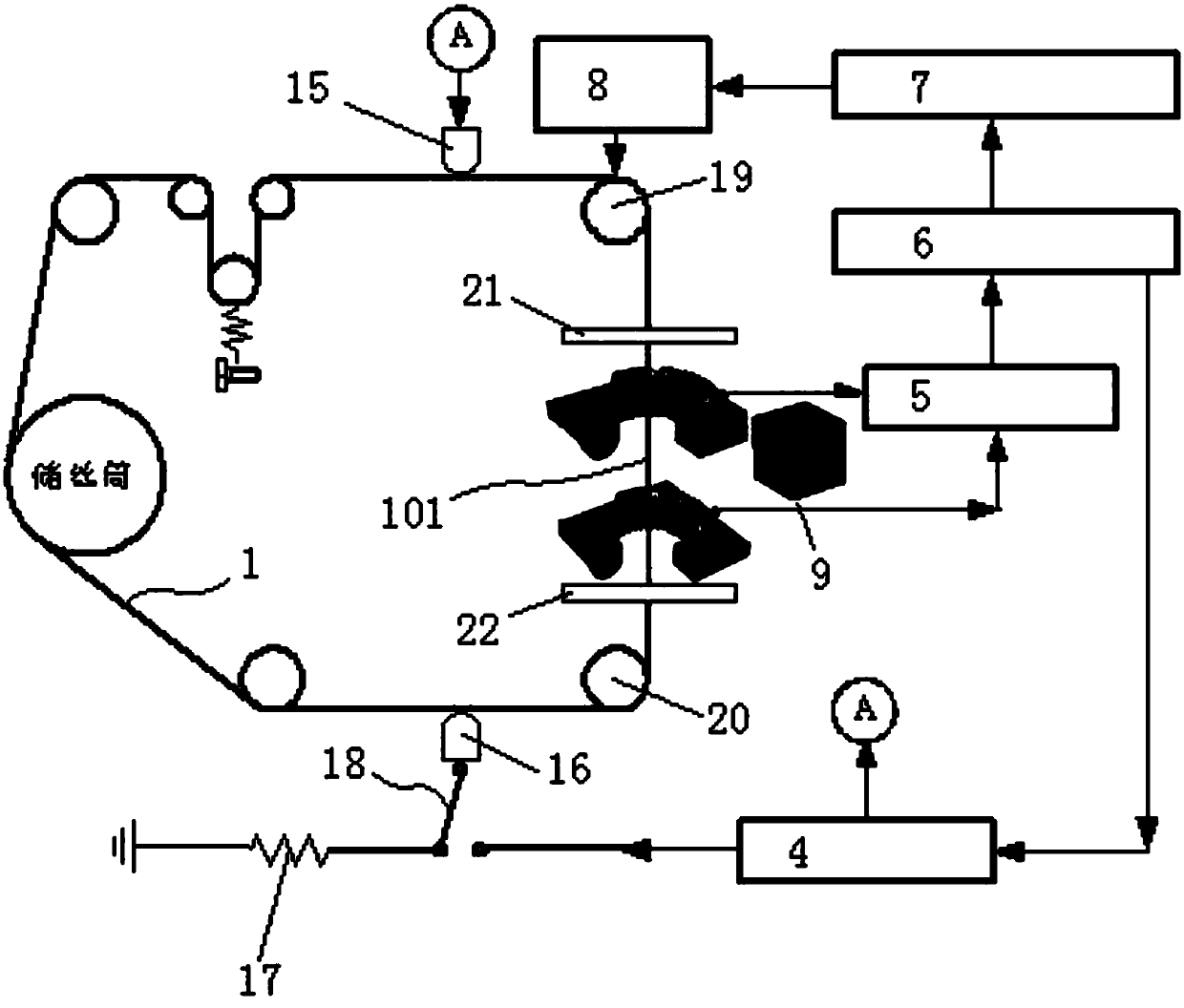

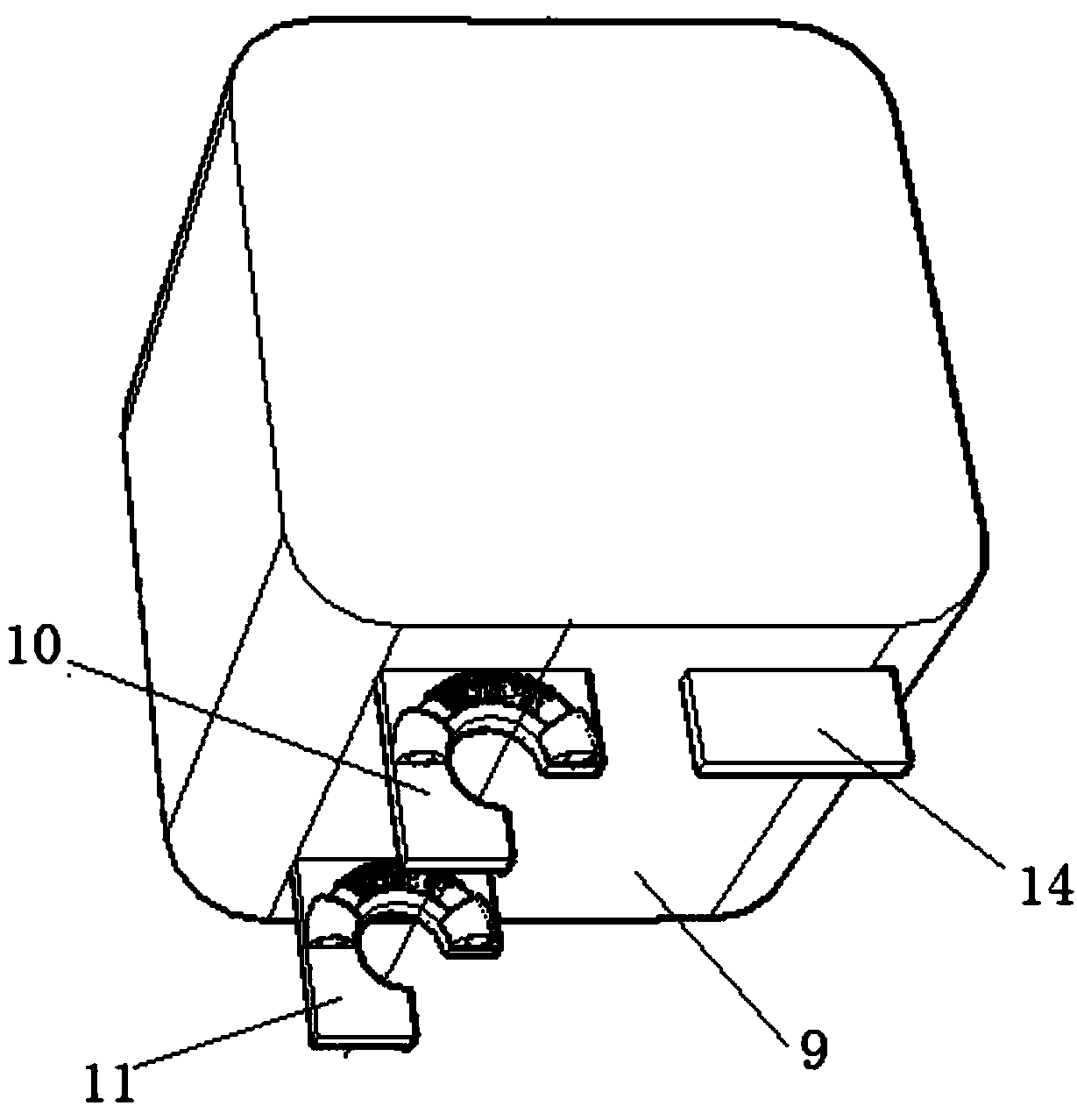

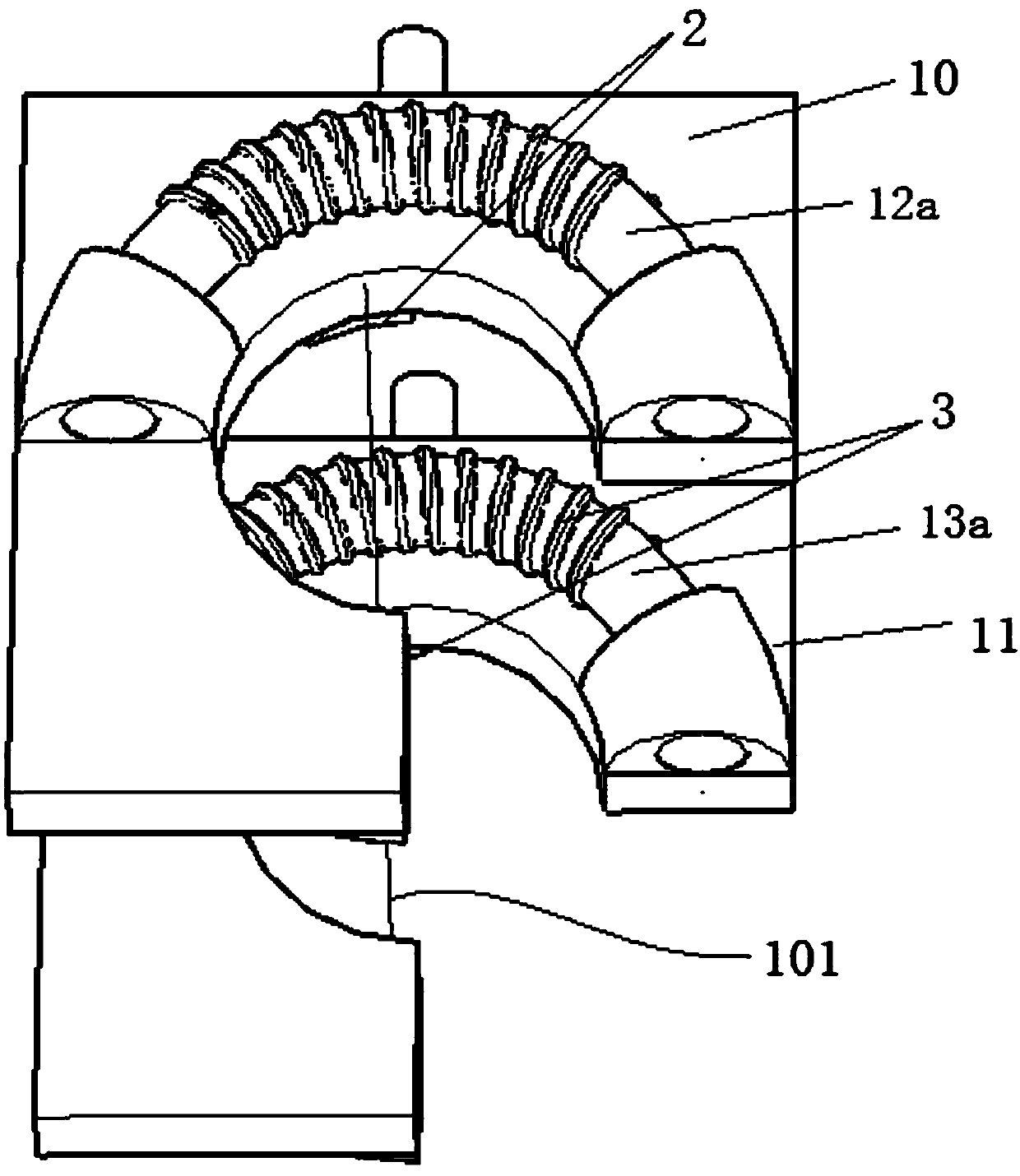

[0051] Figure 1 ~ Figure 4 A specific embodiment of the molybdenum wire vertical measuring and correcting device of the numerically controlled wire cutting machine of the present invention is shown. As everyone knows, the molybdenum wire 1 of the numerically controlled wire cutting machine includes a molybdenum wire linear working section 101 for cutting workpieces, and this device uses It is used to measure and correct the verticality of the molybdenum wire straight working section 101. The CNC wire cutting machine includes a numerical control system 6, a stepping motor 7 connected to the numerical control system, a taper adjustment device 8 connected to the stepping motor, and the taper adjustment device 8 is connected to the upper guide wheel of the molybdenum wire linear working section 101. The actual In application, the stepper motor 7 drives the taper adjustment device 8 to move, and then the position of the upper guide wheel is adjusted through the action of the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com