Automatic grinding equipment for recycling of glass waste

A technology for processing equipment and waste products, which is applied to grinding/polishing equipment, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of reduced work efficiency, high price, troublesome operation, etc., and improve work efficiency , reduce the process, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

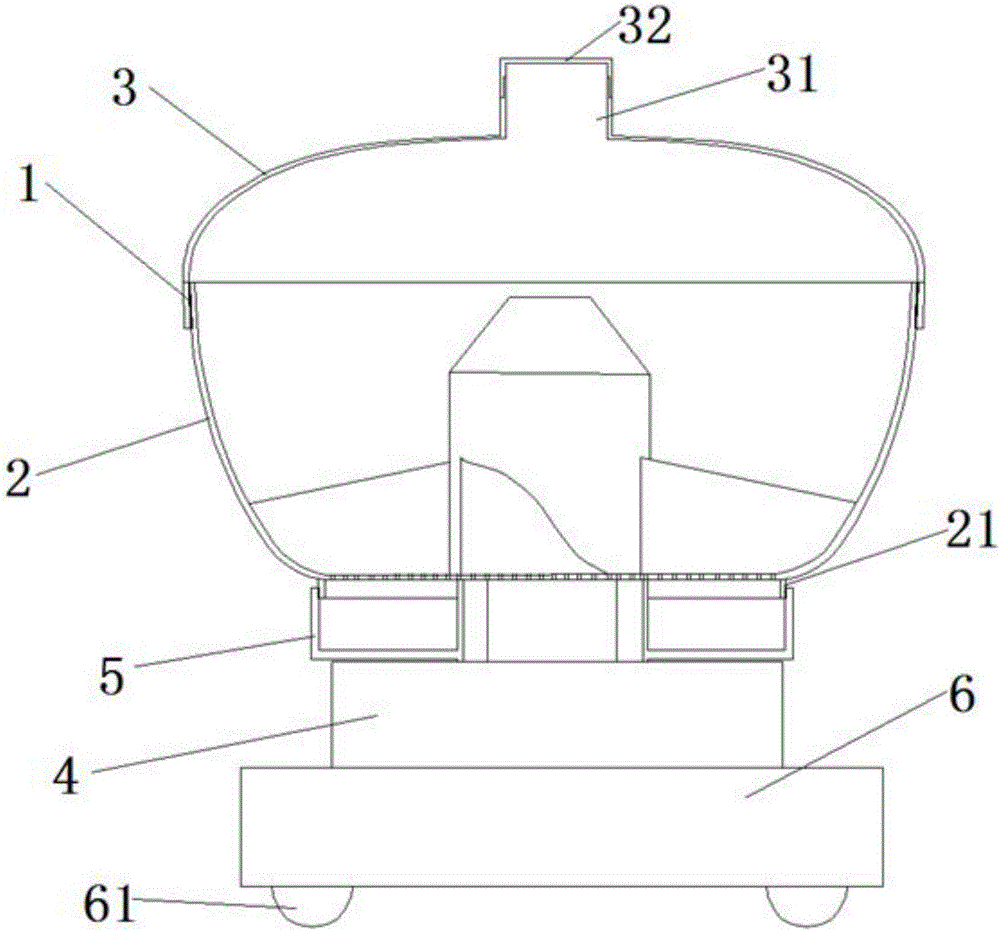

[0018] Such as figure 1 An automatic grinding treatment equipment for recycling glass waste is shown, which includes a grinding box 1, a motor 4, a sewage box 5, and a base 6. The grinding box 1 includes a box body 2 and a box cover 3, and the box body 2 The box cover 3 is threadedly connected, the box body 2 is provided with a rotating stirring paddle, the bottom of the box body 2 is provided with a mounting ring 21, and the bottom of the box body 2 is provided with a sand hole; the mounting ring 21 The drain box 5 is threadedly connected with the mounting ring 21; the bottom of the box body 2 and the drain box 5 are both provided with a bearing channel, and the bearing of the motor 4 passes through the bearing channel to connect to the rotating stirring paddle ; The motor 4 and the base 6 are fixedly connected.

[0019] Put the grindstone into the box 2, then add the glass block to be ground, close the lid 3, turn on the motor 4, and start grinding. During the grinding process...

Embodiment 2

[0021] This embodiment is further improved on the basis of embodiment 1, such as figure 1 As shown in an automatic grinding treatment equipment for recycling glass waste, the box cover 3 is provided with a material inlet 31, the material inlet 31 is connected with a material inlet cover 32, and the material inlet cover 32 is provided with a visible window, so The viewing window is made of quartz, which is convenient for workers to observe the degree of polishing of glass products.

Embodiment 3

[0023] This embodiment is further improved on the basis of embodiment 1, such as figure 1 As shown in an automatic grinding treatment equipment for recycling glass waste, the base 6 is provided with a universal wheel 61 to facilitate the movement of this embodiment; the sewage tank 5 is provided with a plurality of opening and closing doors, so The opening and closing door is connected with the drain groove 5 as a bayonet. The opening and closing door is arranged to clean the drain groove 5 without removing the drain groove 5, and does not need to be shut down for cleaning, which improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com