Series-connection and parallel-connection disc tube type reverse osmosis device for trash leachate treatment and application method thereof

A disc-tube reverse osmosis and landfill leachate technology, which is applied in the field of water treatment, can solve the problems of increasing the pressure damage of the secondary RCDT membrane, shortening the service life of the secondary RCDT membrane, and difficulty in reaching the standard for the ammonia nitrogen content of the effluent, so as to achieve automation operation, reduce labor intensity, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

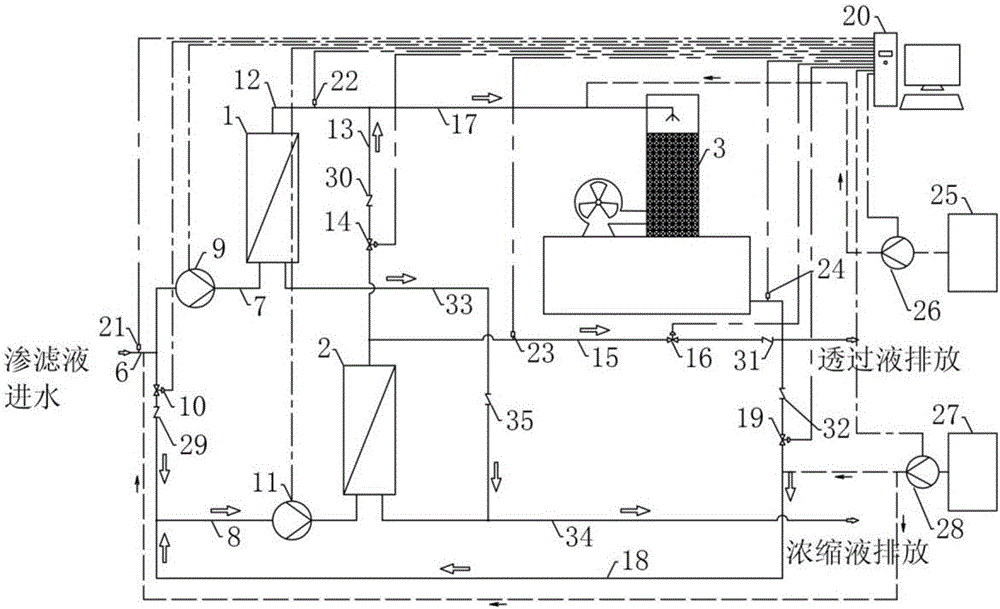

[0035] Such as figure 1 Shown, the present invention is used for a kind of embodiment of the serial and parallel disc tube type reverse osmosis equipment that the present invention is used for landfill leachate treatment, and this series and parallel disc tube type reverse osmosis equipment comprises leachate inlet pipeline, one-stage disc tube type reverse osmosis equipment Osmotic membrane column 1, two-stage disc tube type reverse osmosis membrane column 2, stripping tower 3, alkali chemical tank 25, acid chemical tank 27 and control system. Among them, the leachate water inlet pipeline includes a main water inlet pipe 6, a primary water inlet pipe 7 and a secondary water inlet pipe 8. One end of the primary water inlet pipe 7 is connected to the main water inlet pipe 6, and the other end is connected to the first-stage disc tube reverse osmosis The membrane column 1 is connected, one end of the secondary water inlet pipe 8 is connected to the water inlet main pipe 6, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com