Preparation method of screen protection film and corresponding screen protection film

A technology of screen protective film and base film, applied in the field of optical lighting, can solve problems such as affecting color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application relates to a method for preparing a screen protective film, at least comprising the following steps:

[0040] Step 1, adding a binder and an ultraviolet / blue light absorber to the first organic solvent to obtain a surface coating;

[0041] Step 2, coating the surface coating on the surface of the polyester film to form a coating, and curing the coating to obtain a base film; and

[0042] Step 3: Composite release films on both sides of the base film to obtain the screen protection film of the present application.

[0043] As an improvement to the preparation method of the screen protective film of the present application, the first organic solvent is selected from at least one of aromatic hydrocarbons, esters, and ketones, the aromatic ester solvent is preferably selected from toluene, xylene, and the ketone solvent is preferably selected from acetone, cyclic Hexanone and ester solvents are preferably selected from methyl formate and ethyl acetate. The...

Embodiment 1、2、3、5、6

[0066] Step 1. Add 20-40g of thermosetting acrylate to 100g of mixed solvent of xylene and ethyl acetate (the volume ratio of the two is 2:1-3:1) as a binder to dissolve, and then add a solid content of 40-60 5-10g of ultraviolet / blue light absorber, 0-5g of oil-soluble transparent violet dye, and 0-8g of oil-soluble transparent blue dye to obtain a mixed liquid.

[0067] Step 2, the particle size is 20 ~ 30nm nano-SiO 2 Disperse in xylene to obtain a dispersion liquid with a solid content of 40-50% by weight, and the dispersion liquid also contains 3-7% by weight of D3F. Add 10-20g of the dispersion liquid to the above mixed liquid to obtain a functional surface coating.

[0068] Step 3. Apply the obtained surface coating on the surface of an optical-grade PET film with a thickness of 170-190 microns to form a coating. Curing for 30-40 minutes to obtain a base film.

[0069] Step 4: Composite release films with a peel strength of 3-10g on both sides of the obtained base fi...

Embodiment 4

[0071] Steps 1, 3, and 4 are the same as in Example 1, except that the mixed solution obtained in step 1 is directly transferred to step 3, and the obtained mixed solution is used as a surface coating and coated on the surface of an optical-grade PET film to form a coating.

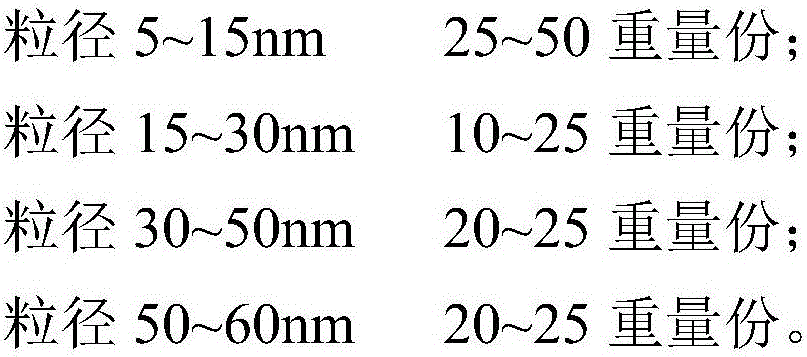

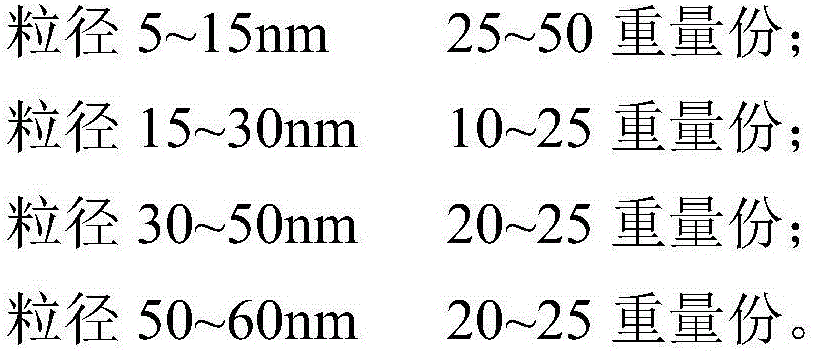

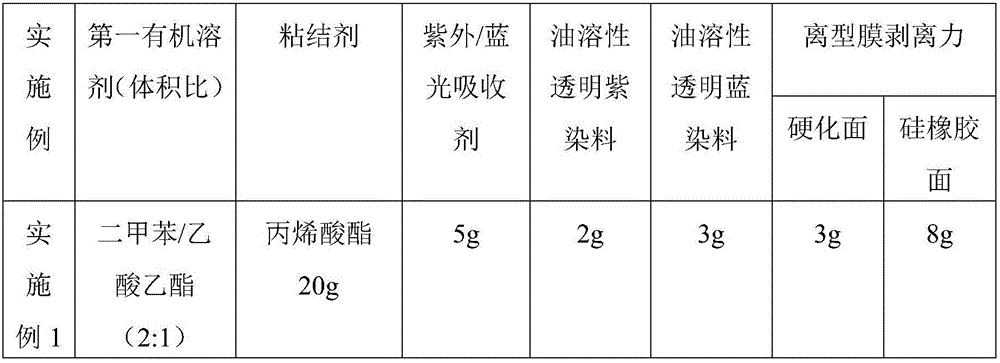

[0072] In Examples 1-6, the first solvent used, adhesive, UV / blue light absorber, oil-soluble transparent violet dye, oil-soluble transparent blue dye, the release film peeling force are as shown in Table 1, UV / Among the blue light absorbers, the types of rare earth oxides, second solvent, particle size distribution, and solid content are shown in Table 2. Nano-SiO 2 The particle size, solids weight content, D3F weight content, and dispersion liquid consumption are shown in Table 3.

[0073] Table 1

[0074]

[0075]

[0076] Table 2

[0077]

[0078]

[0079] table 3

[0080]

[0081] Note: "\" indicates that no substance was added.

[0082] The prepared screen protective film is test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com