Quantum dot printing ink for ink-jet printing and preparing method thereof

A technology of inkjet printing and quantum dots, which is applied in the field of quantum dots, can solve the problems of ink viscosity and surface tension that cannot meet the requirements, achieve the effect of convenient charge transmission, meet the requirements of film formation, and reduce the starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

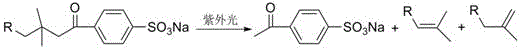

Method used

Image

Examples

Embodiment 1

[0071] Add the following components into an approximately 500mL one-necked flask, and under stirring, the order of addition is: 14wt% oleylamine-stabilized red CdSe / ZnS quantum dots, 52wt% dodecane solvent, 33.5wt% ethylene glycol- Butyl ether, 0.5wt% sodium phthalene sulfonate, and the mixture was stirred for 30 minutes to obtain a quantum dot ink.

[0072] Printed into a red quantum dot layer of 20×30um with a resolution of 200×200ppi by an inkjet printer.

[0073] Place the red quantum dot layer at a power of 5mW / cm 2 Under the low-pressure mercury lamp, the main emission wavelength is 253.7nm, and the irradiation time is 20min. Then heated to 100°C on a hot plate, vacuum 1×10 -6 Volatilize and dry under Torr for 30 minutes to obtain a monochromatic quantum dot light-emitting layer.

Embodiment 2

[0075] Add the following components to an approximately 500 mL high-density polyethylene bottle with stirring in the following order: 10 wt% oleylamine-stabilized green CdZnSe / CdZnS, 23% wt dodecane, 40 wt% decahydronaphthalene, 26wt% 3-dibenzyl ether, 1wt% thermally degradable decomposable surfactant, stirred the mixture for 30 minutes to obtain quantum dot ink.

[0076] With an inkjet printer, it is printed into a green quantum dot layer of 20×30um and a resolution of 200×200ppi.

[0077] Heating to 180° C. on a hot plate, volatilizing and drying under nitrogen flow for 30 minutes, to obtain a monochromatic quantum dot light-emitting layer.

[0078]In summary, the quantum dot ink for inkjet printing provided by the present invention and the preparation method thereof, the prepared quantum dot ink has appropriate viscosity and surface tension, and can meet the film-forming requirements of printers. A quantum dot light-emitting layer with a pixel lattice can be deposited and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com