Inorganic nano material ink and its preparation method and application, qled device

A technology of inorganic nanomaterials and inks, applied in inks, applications, electrical solid devices, etc., can solve the problems of easy volatilization, low viscosity of printing inks, and low boiling points, and meet the requirements of film formation, improve ink dispersion, and dissolve good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The preparation method of the inorganic nano material ink of the present embodiment comprises:

[0064] In the case of stirring, add 10wt% oleylamine-coordinated red CdSe / ZnS quantum dots, 8wt% 1,1-bicyclohexane solvent, 82wt% difluoromethanesulfonamide, stir and mix for 30 minutes to obtain inorganic nano material ink.

[0065] The inorganic nano material ink of this embodiment was printed into a red quantum dot layer of 20×30um and a resolution of 200×200ppi by inkjet printing. Place the printed substrate on a hot stage and heat it to 100°C, vacuum 1×10 - 6 Volatilize and dry under Torr for 30 minutes to obtain a monochromatic quantum dot light-emitting layer.

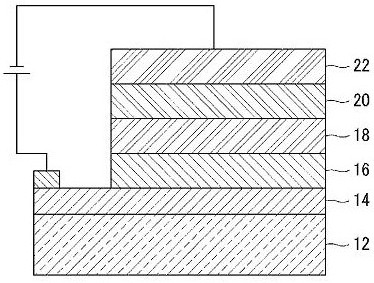

[0066] The QLED device of this embodiment includes an anode 14, a hole transport layer 16, a light emitting layer 18, an electron transport layer 20 and a cathode 22 stacked on a substrate 12, wherein the light emitting layer is the quantum dot light emitting layer of this embodiment.

Embodiment 2

[0068] The preparation method of the inorganic nano material ink of the present embodiment comprises:

[0069] In the case of constant shaking, add 5wt% oleylamine-stabilized green CdZnSe / CdZnS, 20%wt dodecane, 25%wt decahydronaphthalene, 42wt% 1-hexanesulfonamide, shake and mix for 60 minutes to obtain inorganic Nanomaterial inks.

[0070] The inkjet printing method was used to print the inorganic nano material ink of this embodiment into a green quantum dot layer with a size of 20×30um and a resolution of 200×200ppi. Heating on the substrate to 180° C., volatilizing and drying under nitrogen flow for 30 minutes, to obtain a monochromatic quantum dot light-emitting layer.

[0071] The QLED device of this embodiment includes an anode 14, a hole transport layer 16, a light emitting layer 18, an electron transport layer 20 and a cathode 22 stacked on a substrate 12, wherein the light emitting layer is the quantum dot light emitting layer of this embodiment.

Embodiment 3

[0073] The preparation method of the inorganic nano material ink of the present embodiment comprises:

[0074] Add the following components to an approximately 500mL high-density polyethylene bottle, in the case of ultrasonic dispersion, the order of addition is: 20wt% oleylamine-stabilized blue CdS / CdZnS, green CdZnSe / CdZnS, red CdSe / ZnS quantum dots , 20wt% dipentylbenzene, 50%wt tetralin, 10wt% N-tert-butyl-3-chloropropane-1-sulfonamide, ultrasonically dispersed and mixed for 20 minutes to obtain an inorganic nanomaterial ink.

[0075] Through an inkjet printer, print a blue, green and red parallel quantum dot layer of 20×30um and a resolution of 200×200ppi.

[0076] Heat to 150°C on a hot plate, vacuum 1×10 -5 Volatilize and dry under Torr for 30 minutes to obtain a three-color quantum dot light-emitting layer.

[0077] The QLED device of this embodiment includes an anode 14, a hole transport layer 16, a light emitting layer 18, an electron transport layer 20 and a catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com