Green environmental-protection cathode electrophoretic paint

A cathodic electrophoretic coating, green and environmentally friendly technology, applied in the field of coatings, can solve the problems of electrophoretic paint environmental protection performance needs to be improved, to achieve the effect of increasing throwing power, good wear resistance and water resistance, and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

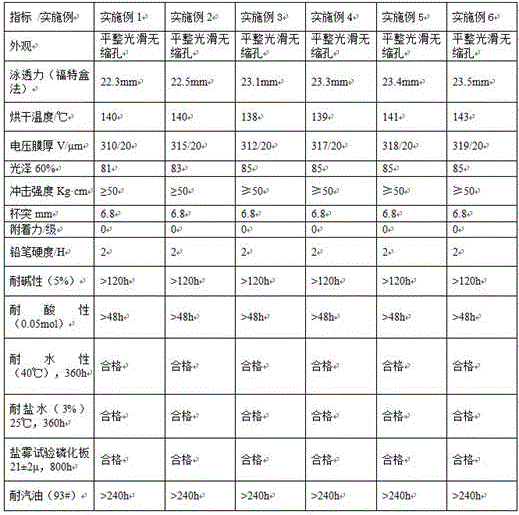

Embodiment 1

[0060] A kind of green environmental protection cathodic electrophoretic paint, comprises by mass parts, 1 part of color paste, 4 parts of emulsion and 5 parts of deionized water;

[0061] The color paste formula includes 20 parts of main resin, 5 parts of alcohol ether co-solvent, 3 parts of organic acid, 0.3 part of emulsifier, 1 part of composite drier, 30 parts of deionized water, 15 parts of filler, the first solid 3 parts of additives and 6 parts of second solid additives, 6 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a ratio of 1:3:2 by mass; The particle size range of solid additives is 0.8-5 microns; among them, the particles of 0.8-1 microns account for 20% of the total weight of solid additives; the particles of 1-2 microns account for 10% of the total weight of solid additives; the balance is 3 microns Particles; the second solid additive is a mixture of molybdenum disulfide nanospheres ...

Embodiment 2

[0078] Green and environmentally friendly cathodic electrophoretic coatings, including, by mass parts, 2 parts of color paste, 6 parts of emulsion and 5 parts of deionized water;

[0079] The color paste formula includes 30 parts of main resin, 10 parts of alcohol ether co-solvent, 8 parts of organic acid, 0.7 part of emulsifier, 5 parts of composite drier, 40 parts of deionized water, 20 parts of filler, the first solid 7 parts of additives, 1.5 parts of the second solid additive, 9 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a ratio of 1:4:1 by mass;

[0080] The particle size range of the first solid additive is 0.8-5 microns; wherein, the particles of 0.8-1 microns account for 40% of the total weight of the solid additive; the particles of 1-2 microns account for 30% of the total weight of the solid additive; the balance is 5 Micron particles;

[0081] The second solid additive is a mixture of ...

Embodiment 3

[0099] Green and environmentally friendly cathodic electrophoretic coatings, including, by mass parts, 1.2 parts of color paste, 5 parts of emulsion and 6 parts of deionized water;

[0100] The color paste formula includes 25 parts of main resin, 8 parts of alcohol ether co-solvent, 5 parts of organic acid, 0.5 part of emulsifier, 4 parts of composite drier, 35 parts of deionized water, 15-20 parts of filler, the first solid 4 parts of the additive, 5 parts of the second solid additive and 7 parts of the first composite regulator composed of trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene in a ratio of 1:3:1 by mass;

[0101] The particle size range of the first solid additive is 0.8-5 microns; wherein, the particles of 0.8-1 microns account for 30% of the total weight of the solid additives; the particles of 1-2 microns account for 20% of the total weight of the solid additives; the balance is 3 - particles of 5 microns;

[0102] The second solid additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com