Preparation method of fluorescent carbon nanoparticles by direct hydrothermal carbonization of kelp

A technology of carbon nano-particles and hydrothermal carbonization, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., to achieve excellent fluorescence performance, strong practicability, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

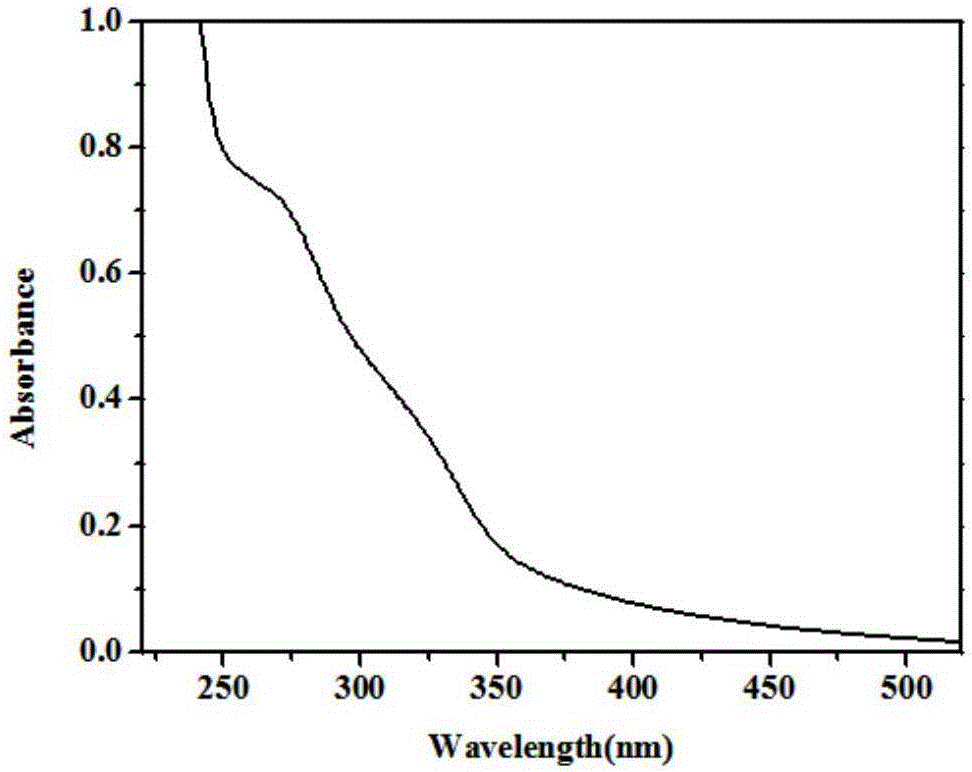

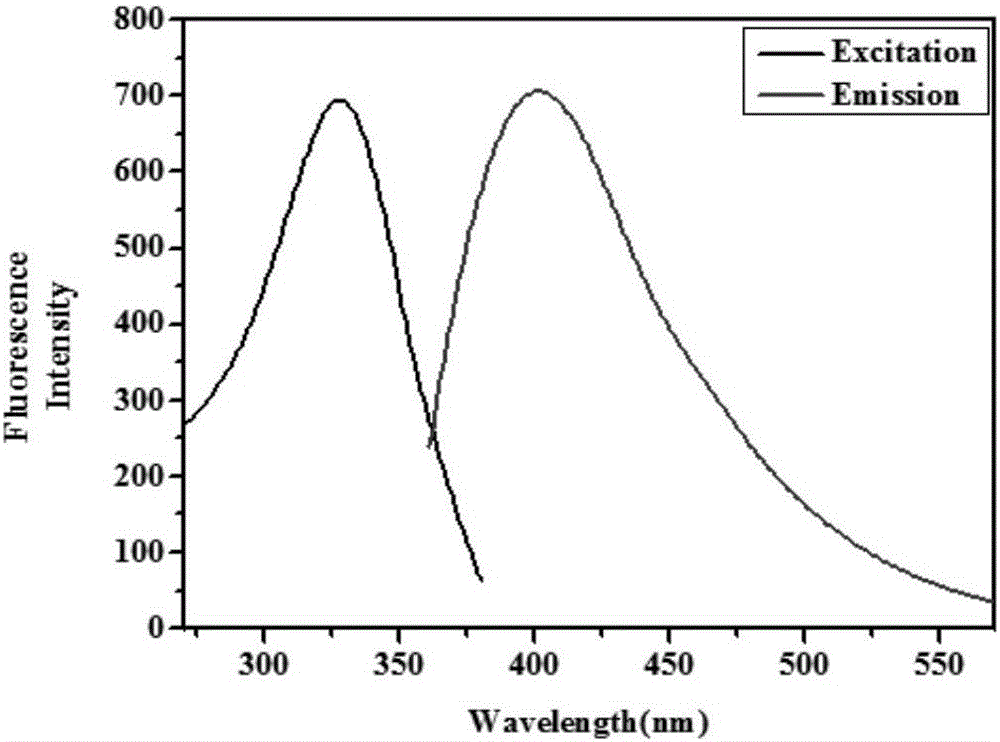

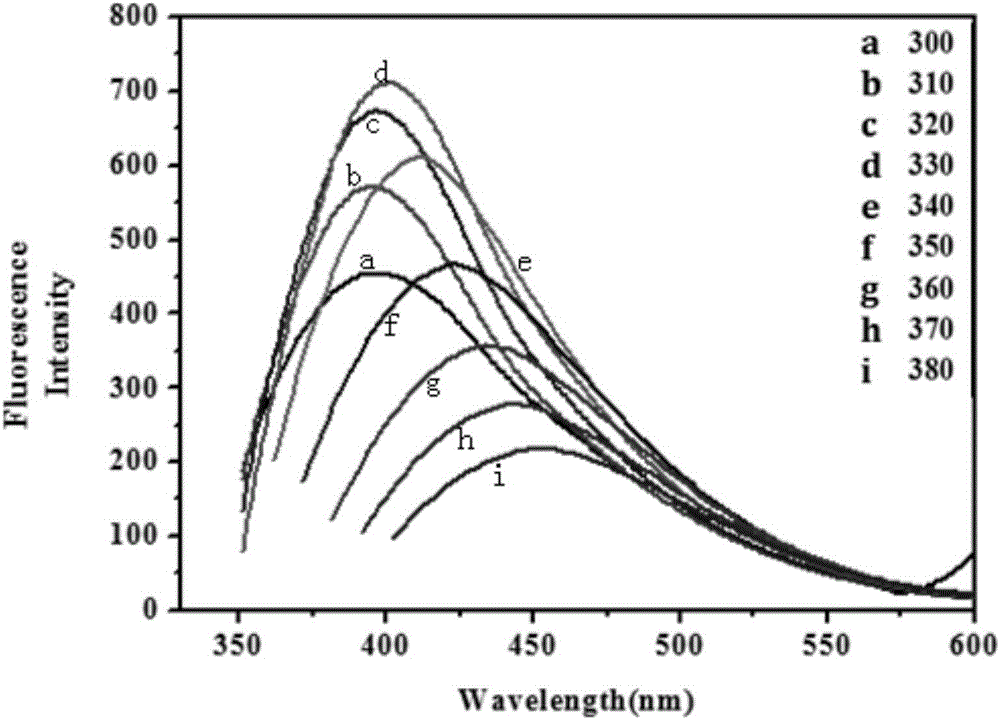

[0045] Direct hydrothermal carbonization of kelp to prepare fluorescent carbon nanoparticles, the detailed preparation steps are as follows: (1) Wash 250 g of freshly purchased kelp with water, cut into small pieces and place them on a tray, then transfer them to an oven at 60 ° C. Drying treatment, crush it into powder with a pulverizer, sieve the powder through an 80-mesh sieve to obtain fine and uniform dry seaweed powder; (2) Weigh 1g dry seaweed powder and place it in a clean beaker, pour it into Add 2 mL of ethanol, stir well to obtain a paste, transfer the paste to an autoclave, and react continuously for 10 h at 120°C to prepare fluorescent carbon nanoparticles; (3) add the product to deionized water, disperse After uniformity, vacuum filtration is carried out, and the obtained filtrate is removed by rotary evaporation at 60°C to remove a large amount of solvent, and then centrifuged at 8000rpm for 25min, and the obtained precipitate is dried in an oven to obtain carbon...

Embodiment 2

[0048] The detailed preparation steps are as follows: (1) Wash 500g of freshly purchased kelp with water, cut it into small pieces, place it on a tray, then transfer it to an oven, dry it at 70°C, and crush it with a pulverizer into a powder, and the powder is sieved through a 100-mesh sieve to obtain fine and uniform dry seaweed powder; (2) Weigh 2g of dry seaweed powder and place it in a clean beaker, add 5mL propanol to it, and stir well to obtain a paste transfer the paste to a high-pressure reactor, and react continuously at 140°C for 8 hours to prepare fluorescent carbon nanoparticles; (3) add the product to deionized water, disperse it evenly, and carry out vacuum filtration, and the obtained filtrate is in Remove a large amount of solvent by rotary evaporation at 70°C, then centrifuge at 10,000rpm for 20min, dry the resulting precipitate in an oven to obtain carbon nanoparticle powder, take a certain amount of the powder and disperse it in deionized water to obtain a di...

Embodiment 3

[0050] The detailed preparation steps are as follows: (1) Wash 750g of freshly purchased kelp with water, cut it into small pieces and place it on a tray, then transfer it to an oven, dry it at 80°C, and crush it with a pulverizer into a powder, and the powder is sieved through a 120-mesh sieve to obtain fine and uniform dry seaweed powder; (2) Weigh 3g dry seaweed powder and place it in a clean beaker, add 10mL n-butanol to it, stir well to obtain a paste transfer the paste to a high-pressure reactor, and react continuously at 160°C for 6 hours to prepare fluorescent carbon nanoparticles; (3) add the product to deionized water, disperse it evenly, and carry out vacuum filtration, and the obtained filtrate Remove a large amount of solvent by rotary evaporation at 80°C, then centrifuge at 12000rpm for 15min, dry the resulting precipitate in an oven to obtain carbon nanoparticle powder, take a certain amount of the powder and disperse it in deionized water to obtain carbon nanopa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com