A flame-retardant and smoke-suppressing plant fiber paper-based material and its preparation method

A plant fiber and paper-based technology, applied in the field of flame-retardant materials, can solve problems such as the difficulty of endowing plant fiber paper-based materials with flame-retardant and smoke-suppressing properties, limiting the use range of flame-retardant paper-based materials, and affecting the physical properties of paper-based materials. Achieve the effects of reducing thermal decomposition and flammable gas generation, good charcoal coverage, and reducing combustion smoke production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

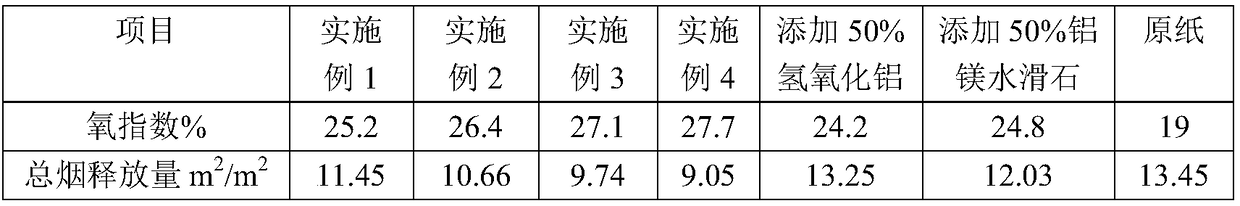

Examples

Embodiment 1

[0027] A flame-retardant and smoke-suppressing plant fiber paper-based material, prepared by the following method:

[0028] ① Pour 300 kg of phosphoric acid with a concentration of 85% into the reactor, heat and stir, and add 255 kg of urea when the temperature rises to 80°C;

[0029] ②When the temperature rises to 130°C, add 15 kg of diatomite and keep it warm for 5 minutes. When the temperature continues to rise to 140°C, add 3 kg of nano-titanium dioxide, keep it warm for 10 minutes, and pour out the product;

[0030] ③The product was cured at 250°C for 2.5 hours, and the cured material was ground and sieved to obtain the ammonium polyphosphate-diatomaceous earth / nano-titanium dioxide composite flame retardant and smoke suppressant for paper;

[0031] ④ Add the composite flame retardant and smoke suppressant to the regenerated fiber pulp, and prepare the pulp according to the ratio of regenerated plant fiber: composite flame retardant and smoke suppressant: cationic polyacr...

Embodiment 2

[0033] A flame-retardant and smoke-suppressing plant fiber paper-based material, prepared by the following method:

[0034] ① Pour 300 kg of phosphoric acid with a concentration of 85% into the reactor, heat and stir, and add 255 kg of urea when the temperature rises to 82°C;

[0035] ②When the temperature rises to 133°C, add 30 kg of diatomite and keep it warm for 6 minutes. When the temperature continues to rise to 142°C, add 5 kg of nano-titanium dioxide, keep it warm for 15 minutes, and pour out the product;

[0036] ③The product was cured at 254°C for 2.6 hours, and the cured material was ground and sieved to obtain the ammonium polyphosphate-diatomaceous earth / nano-titanium dioxide composite flame retardant and smoke suppressant for paper;

[0037] ④ Add the composite flame retardant and smoke suppressant to the regenerated fiber pulp, and prepare the pulp according to the ratio of regenerated plant fiber: composite flame retardant and smoke suppressant: cationic polyacr...

Embodiment 3

[0039] A flame-retardant and smoke-suppressing plant fiber paper-based material, prepared by the following method:

[0040] ① Pour 300 kg of phosphoric acid with a concentration of 85% into the reactor, heat and stir, and add 285 kg of urea when the temperature rises to 83°C;

[0041] ② When the temperature rises to 134°C, add 30 kg of diatomite and keep it warm for 8 minutes. When the temperature continued to rise to 143°C, 10 kg of nano-titanium dioxide was added, kept for 30 minutes, and the product was poured out;

[0042] ③The product was cured at 256°C for 2.8 hours, and the cured material was ground and sieved to obtain the ammonium polyphosphate-diatomaceous earth / nano-titanium dioxide composite flame retardant and smoke suppressant for paper;

[0043] ④ Add the composite flame retardant and smoke suppressant to the regenerated fiber pulp, and prepare the pulp according to the ratio of regenerated plant fiber: composite flame retardant and smoke suppressant: cationic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com