High sulfur content gas reservoir sulfur solubility online test apparatus and test method thereof

An on-line testing, high-sulfur technology, which is applied in the direction of chemical analysis by combustion and material absorption and weighing, can solve problems such as scrapping, gas well shutdown, formation porosity and permeability reduction, etc., and achieves high test sensitivity and consistency Good performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

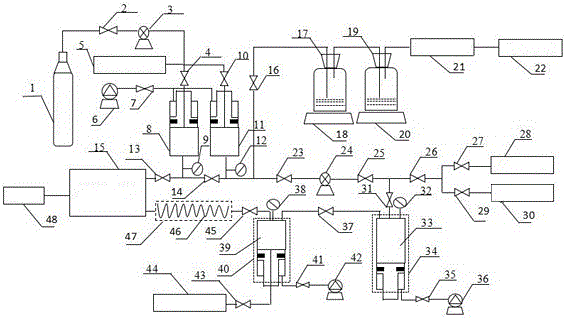

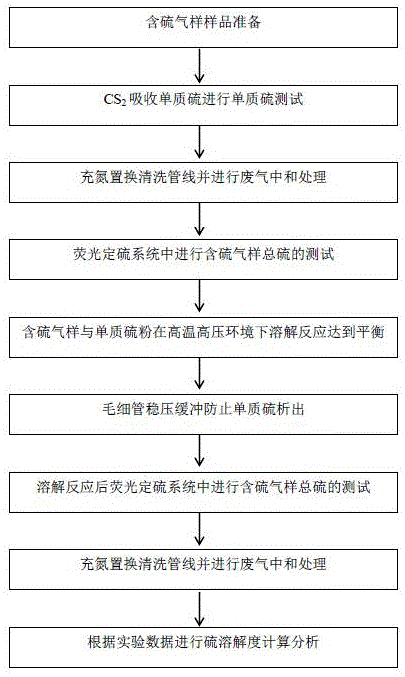

[0076] An online testing device for sulfur solubility of high-sulfur gas reservoirs:

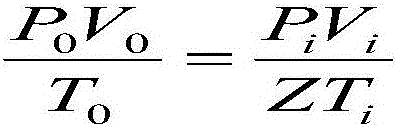

[0077] like figure 1As shown, the device mainly includes a sulfur gas sample bottle 1, a gas source control valve 2, a gas booster pump 3, a piston intake valve 4, a nitrogen replacement device 5, an electric pump 6, and an electric pump control valve 1 7. Piston-type quantitative container 8, pressure sensor one 9, control valve 10, elemental sulfur test piston quantitative container 11, pressure sensor two 12, fluorescent sulfur determination system intake valve 13, gas circulation valve 14, fluorescent sulfur determination system 15, Check valve 16, CS 2 Sulfur absorption container 17, electronic balance 18, CS 2 Sulfur absorbing container II 19, electronic balance II 20, gas meter 21, H 2 S neutralization tank 1 22, pump intake valve 23, gas booster pump 2 24, pipeline control valve 25, cleaning tail gas control valve 26, tail gas valve 27, H 2 S neutralization pool 2 28, cleaning va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com