Solar cell assembly package glue film and application thereof

A technology for solar cells and encapsulation films, applied in the field of solar cells, can solve the problems of low conversion efficiency and low conversion efficiency of solar cells, and achieve the effects of high conversion efficiency, reduced reflection and reduced surface reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

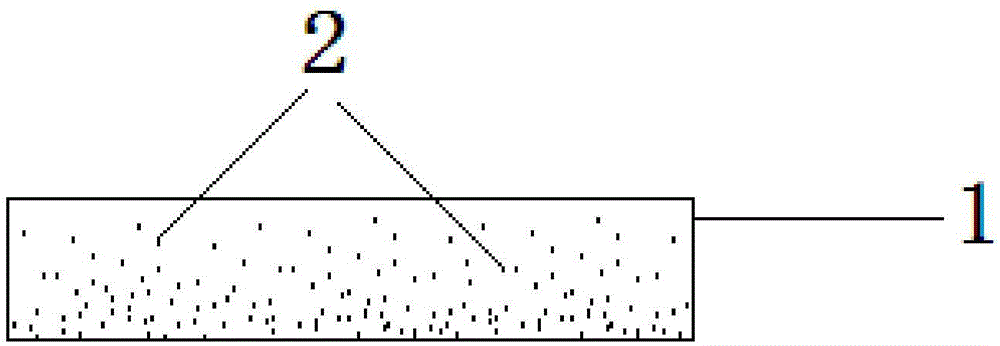

[0029] An encapsulation adhesive film for solar cell modules, which is composed of a transparent organic adhesive film 1 and spectral down-conversion particles 2, the spectral down-conversion particles 1 are distributed in the transparent organic adhesive film 2, and the spectral down-conversion particles 1 are made of ethylene-vinyl acetate Ester copolymer, spectrum down-conversion particle 2 adopts yttrium aluminum garnet phosphor of rare earth element cerium.

[0030] The preparation method is as follows: in the process of preparing the transparent ethylene-vinyl acetate copolymer, the yttrium aluminum garnet phosphor powder containing rare earth element cerium is mixed into the mixture of three different phosphor powder contents. According to the size of the fluorescent powder content, it is poured into the container in turn to form a mixture with a gradually increasing particle distribution density from top to bottom, and then it is cured and formed to form a film.

Embodiment 2

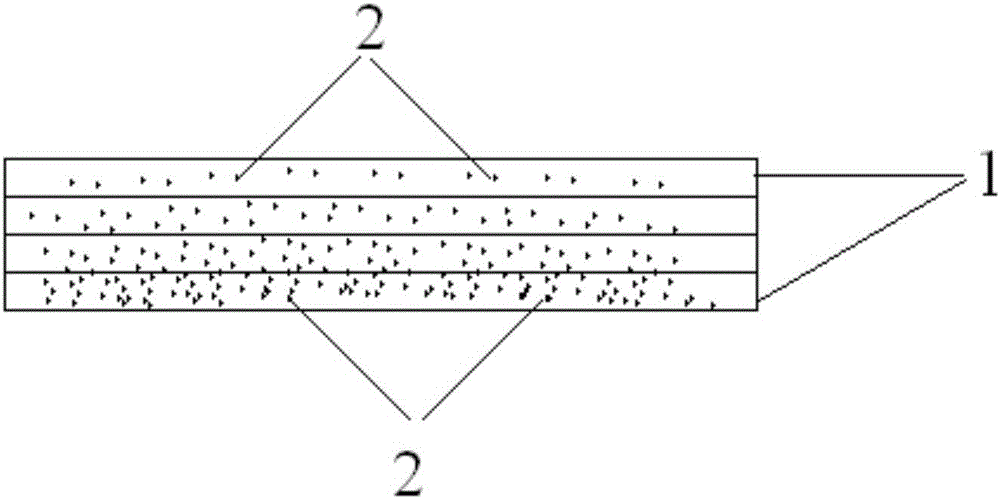

[0032] An encapsulation adhesive film for solar cell modules, which is composed of a transparent organic adhesive film 1 and spectral down-conversion particles 2, the spectral down-conversion particles 1 are distributed in the transparent organic adhesive film 2, the spectral down-conversion particles 1 are made of organic silica gel, and the spectral down-conversion particles 1 are made of organic silica gel. The down-conversion particle 2 adopts yttrium aluminum garnet phosphor containing rare earth elements cerium and ytterbium.

[0033] The preparation method is as follows: in the process of preparing transparent organic silica gel, yttrium aluminum garnet phosphor powder containing rare earth elements cerium and ytterbium is added to make a mixture of five kinds of phosphor powders with different contents. Each mixture is cured and formed to form adhesive films with different phosphor particle densities.

Embodiment 3

[0035] An encapsulation adhesive film for solar cell modules, which is composed of a transparent organic adhesive film 1 and spectral down-conversion particles 2, the spectral down-conversion particles 1 are distributed in the transparent organic adhesive film 2, and the spectral down-conversion particles 1 are made of ethylene-vinyl acetate Ester copolymer, spectral down conversion particles 2 using quantum dots.

[0036] The preparation method is as follows: in the process of preparing the transparent ethylene-vinyl acetate copolymer, quantum dots are added to prepare a mixture of three different quantum dot contents. According to the size of the quantum dot content, it is poured into the container in turn to form a mixture with a gradually increasing particle distribution density from top to bottom, and then it is cured and formed to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com