Energy-saving copper-aluminum composite conductor plug-in busbar in switchgear

A copper-aluminum composite, energy-saving technology, applied in the direction of cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of burning insulation layer, equipment failure, low structural strength, etc., and achieve large carrying capacity, low cost, and fireproof performance and high fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

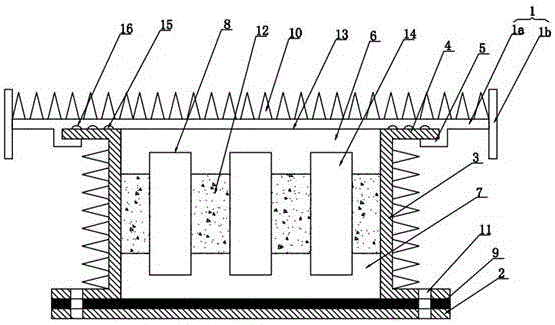

[0014] figure 1 Shown is an energy-saving copper-aluminum composite conductor plug-in bus duct for switchgear provided by the present invention, including a lower cover 2, an upper cover 1, and an upper cover 1 and a lower cover 2 The tank 13 formed by two side plates 3 between them; the upper cover plate 1 is an I-shaped structure, and the upper cover plate 1 includes a horizontal plate 1a and a baffle plate 1b installed at both ends of the horizontal plate 1a; the horizontal plate 1 The plate 1a is installed on the side plate 3, which facilitates the installation of the upper cover plate 1, and at the same time enables the upper cover plate 1 to be installed horizontally on the side plate 3; the upper and lower ends of the side plate 3 are provided with ear plates 4, and The lower surface of the horizontal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com