Assembly method of stainless steel tube shell and capillary core in a loop heat pipe evaporator

A stainless steel tube, loop heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low reliability, low assembly success rate, difficult assembly operation, etc., to achieve high connection reliability, conducive to heating Control and eliminate bounce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

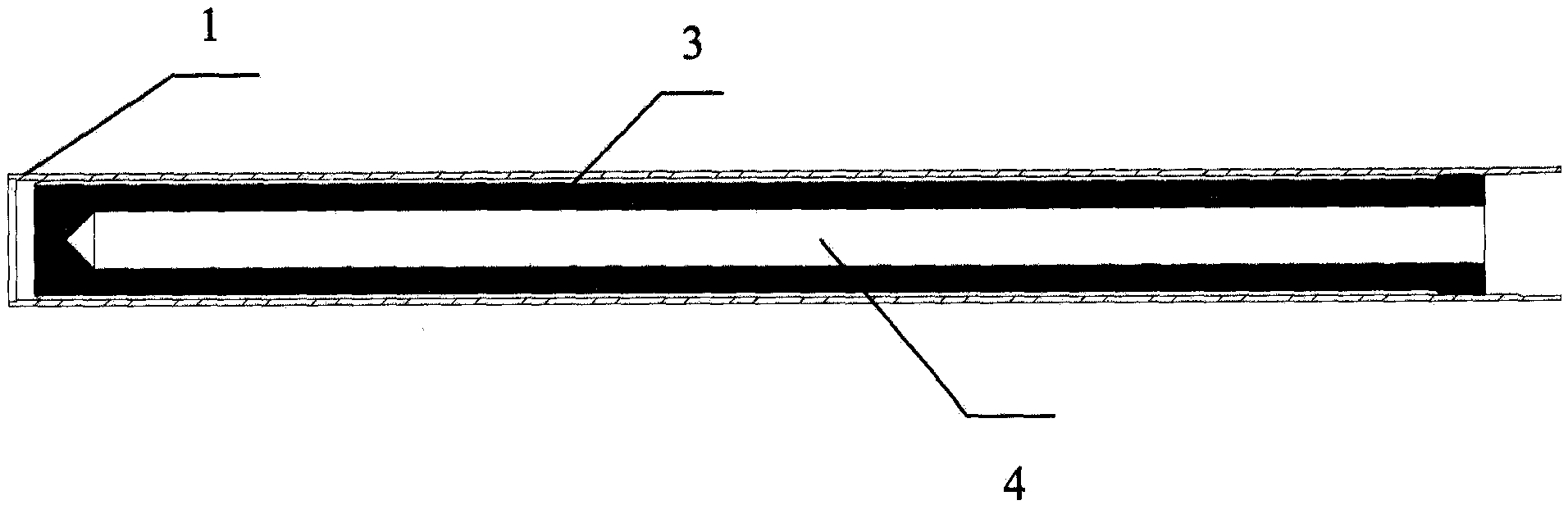

[0041] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

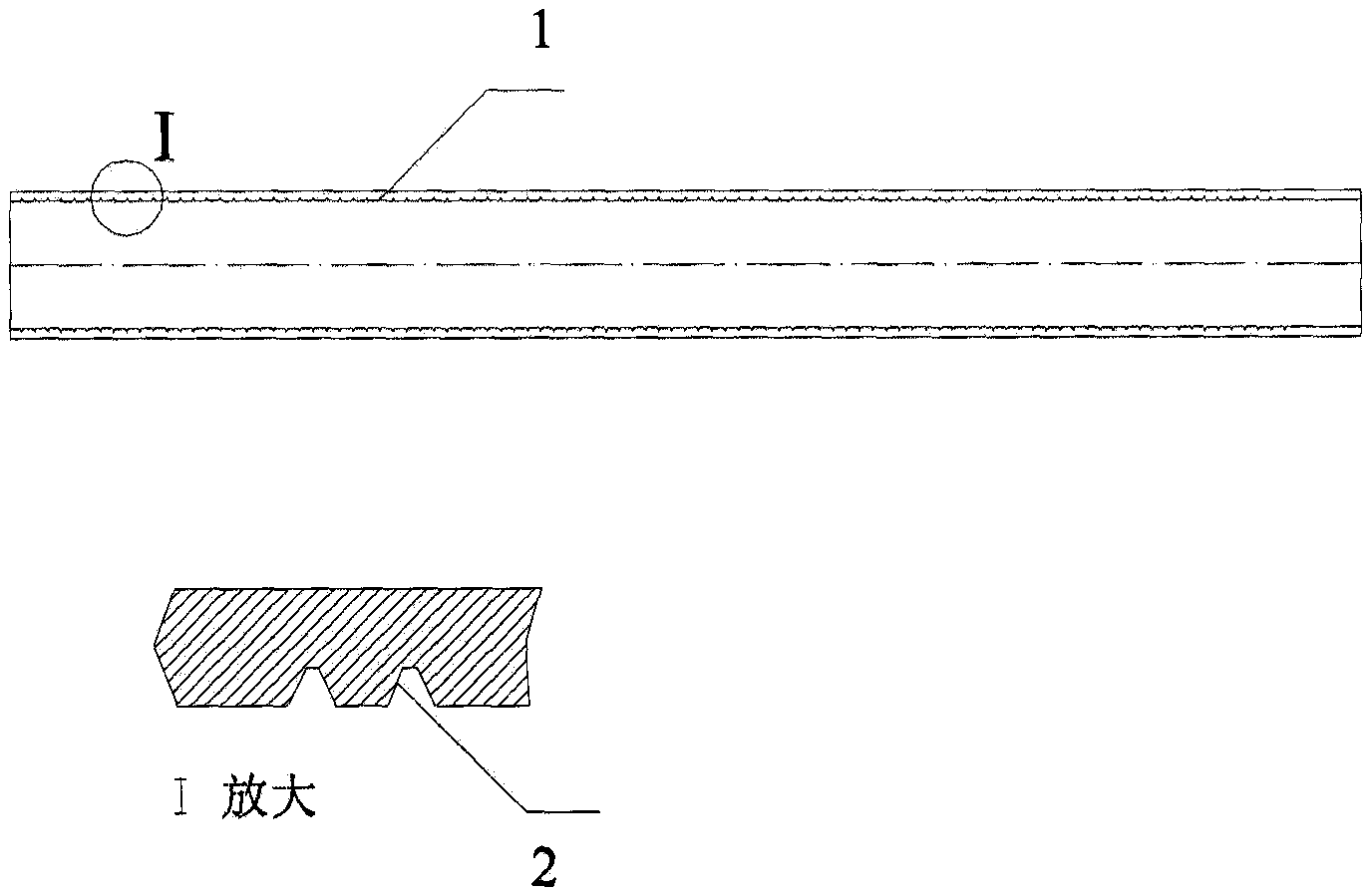

[0042] The stainless steel shell 1 to be assembled in the loop heat pipe evaporator is made of ordinary pipes by mechanical processing. The preparation process includes roughing the outer circle, boring the inner hole, reaming the inner hole, tapping, fine reaming the inner hole and finishing. The outer circle of the car, the specific processing technology is the traditional preparation technology, the processed stainless steel shell 1 is a round tube structure with internal threads 2 on the inner wall, such as figure 1 Shown is a sectional view of the structure of the stainless steel tube shell of the present invention.

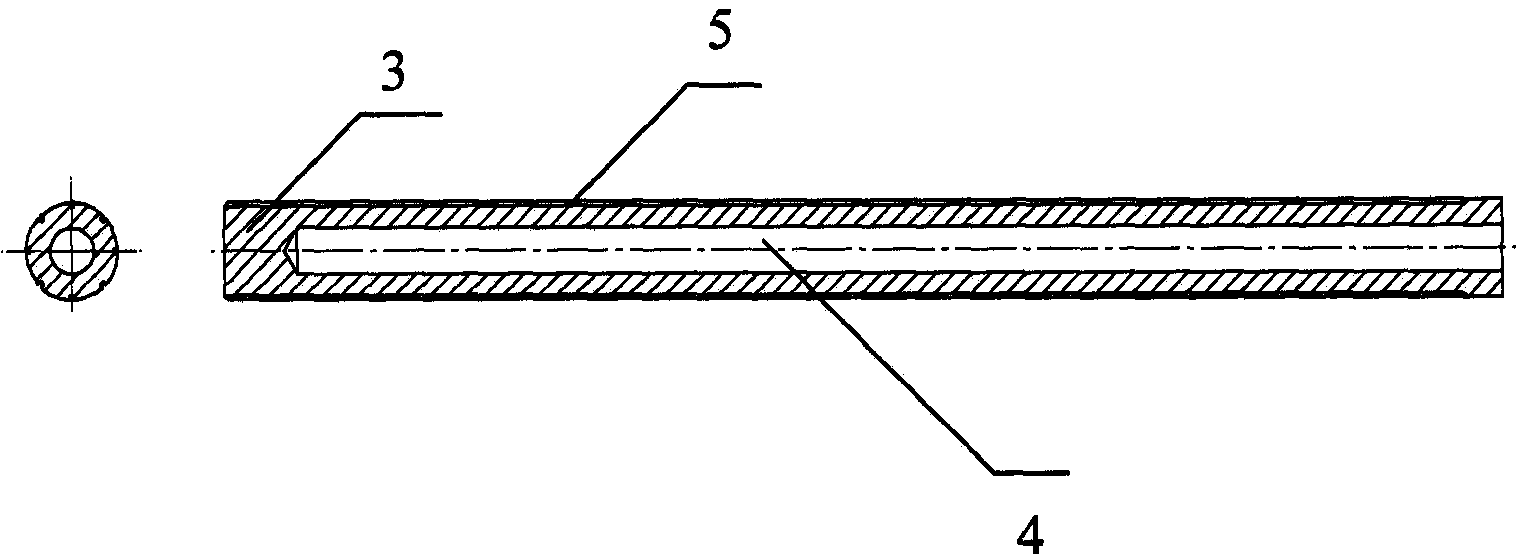

[0043] The material of the capillary wick 3 to be assembled in the loop heat pipe evaporator is a new type of material, the brand is Ni3, which is manufactured by powder metallurgy with a purity of 99.99% nickel powder. In order to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com