Food-borne selenium-rich antioxidative peptide and preparation method thereof

An antioxidant peptide, food-derived technology, applied in the field of food-derived selenium-rich antioxidant peptides and its preparation, can solve the problems of selenium-rich antioxidant peptide research and related patents that have not been reported, and selenium-rich antioxidant peptides are few , to achieve the effects of reducing subsequent desalination steps, reducing the generation of bitter peptides, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

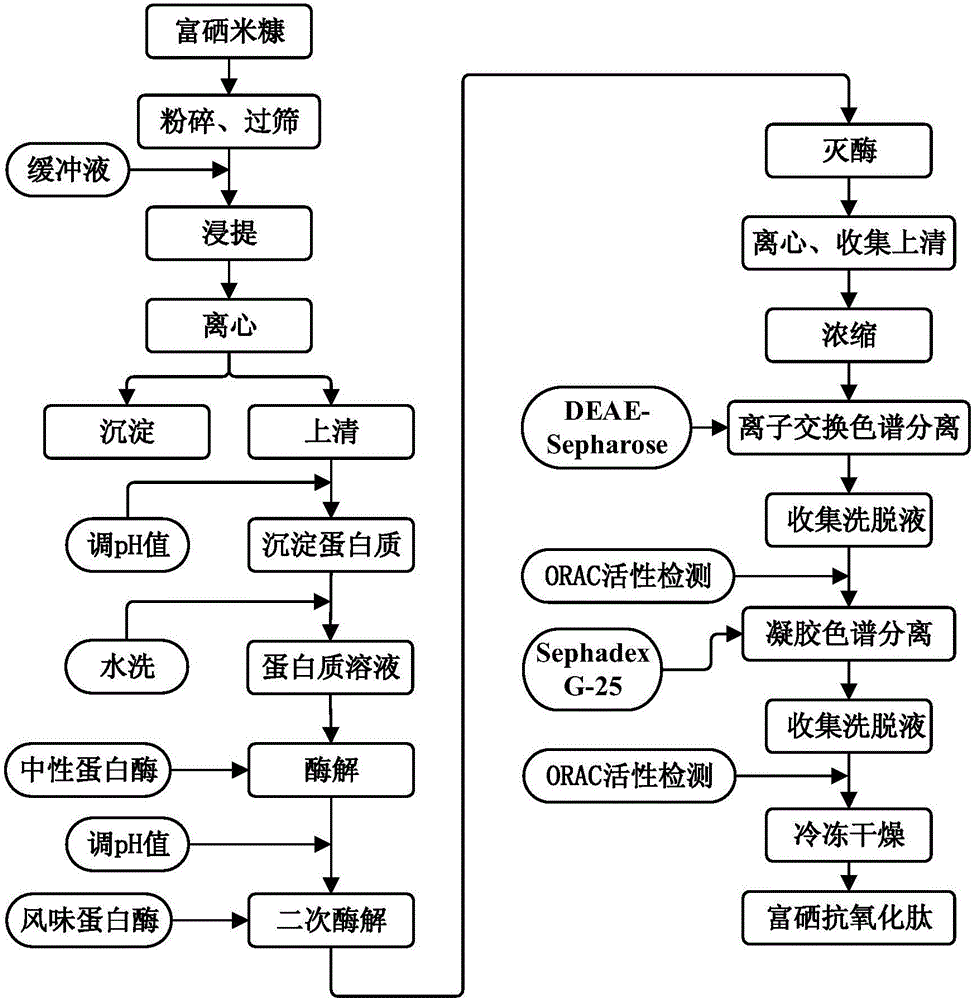

[0032] The invention provides a preparation method of food-derived selenium-rich antioxidant peptides, such as figure 1 As shown, including the following steps:

[0033] 1) The selenium-rich rice bran is crushed and passed through a 60-100 mesh sieve, and immersed in a food-grade phosphate buffer with a material-to-liquid ratio (g / mL) of 14 to 18 and a pH of 8.0 to 9.5 at 20 to 45°C Extract for 2 to 4 hours, extract twice, centrifuge at 6000 revolutions / centrifuge for 20 minutes, combine the supernatant; adjust the pH of the supernatant to 4.5 with dilute hydrochloric acid, precipitate the protein, centrifuge, discard the supernatant, and wash the precipitated protein twice with water spare;

[0034] 2) In the precipitated protein obtained in step 1), add water with a mass / volume ratio of 16 to 1 12, stir and homogenize, and then mix the neutral protease to the precipitated protein with a mass ratio of 2% to 5% at a temperature of 45 Enzymatic hydrolysis at ~55℃ and pH 6.5-7.5 for...

Embodiment 1

[0037] The present invention provides a preparation method of food-derived selenium-enriched antioxidant peptide, which comprises the following steps:

[0038] 1) Selenium-enriched rice bran is crushed and passed through an 80-mesh sieve. In a food-grade phosphate buffer with a material-to-liquid ratio (g / mL) of 16 and a pH of 8.5, it is leached at 35°C for 3 hours, and leached twice. Centrifuge at 6000 rpm for 20 minutes and combine the supernatant; adjust the pH of the supernatant to 4.5 with dilute hydrochloric acid, precipitate the protein, centrifuge, discard the supernatant, and wash the precipitated protein twice for use;

[0039] 2) To the precipitated protein obtained in step 1), add water with a mass / volume ratio of 18, stir and homogenize, and then set the mass ratio of neutral protease to precipitated protein to 4%, temperature of 50°C, and pH of 7.0 Under the conditions of enzymatic hydrolysis for 1.2 hours, after enzymatic hydrolysis, adjust the enzymatic hydrolysis s...

Embodiment 2

[0042] The present invention provides a preparation method of food-derived selenium-enriched antioxidant peptide, which comprises the following steps:

[0043] 1) The selenium-rich rice bran is crushed and passed through a 60-mesh sieve, and extracted twice in a food-grade phosphate buffer with a material-to-liquid ratio (g / mL) of 18 and a pH of 8.0 at 45°C for 2 hours. Centrifuge at 6000 rpm for 20 minutes and combine the supernatant; adjust the pH of the supernatant to 4.5 with dilute hydrochloric acid, precipitate the protein, centrifuge, discard the supernatant, and wash the precipitated protein twice for use;

[0044] 2) In the precipitated protein obtained in step 1), add water with a mass / volume ratio of 16 and stir and homogenize. Then, the mass ratio of neutral protease to precipitated protein is 5%, the temperature is 45°C, and the pH value is 7.5. Enzymatic hydrolysis under conditions for 1.0 hour, after enzymatic hydrolysis, adjust the enzymatic hydrolysis solution to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com