Roasting flue gas treatment system and treatment method thereof

A flue gas and roasting technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as high system energy consumption, high equipment investment, and serious equipment corrosion, and achieve simple operation and maintenance and simple process flow , no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

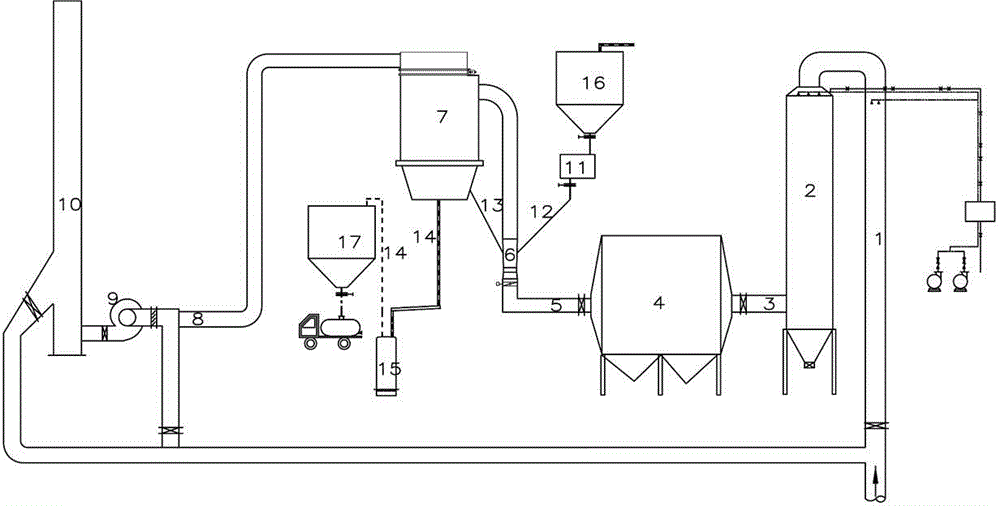

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

[0038] Such as figure 1 A kind of roasting flue gas control system of the present invention as shown, comprises flue 1, and flue 1 is communicated with the bottom of cooling tower 2 top and chimney 10 respectively, and the bottom of cooling tower 2 is through electric tar catcher flue 3 and electric catches tar. The electric tar catcher 4 is connected to the reactor 6 through the back flue 5 of the electric tar catcher, the reactor 6 is connected to the digester 11 through the raw material delivery pipeline 12, and the reactor 6 is connected to the upper part of the bag filter 7 through a pipe , the lower part of the bag filter 7 is connected to the reactor 6 through the circulating material delivery pipeline 13, the digester 11 is connected to the raw material bin 16 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com