A kind of membrane emulsifier and emulsion preparation method

A membrane emulsifier and membrane emulsification technology, which is applied in the field of membrane emulsification, can solve the problems of large influence of microsphere particle size and batch repeatability, difficult to control pressure accuracy and stability, and high requirements for pressure gauge accuracy and stability. To achieve the effect of simplifying the accessories of membrane emulsification equipment, ensuring batch repeatability, and facilitating standardized and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

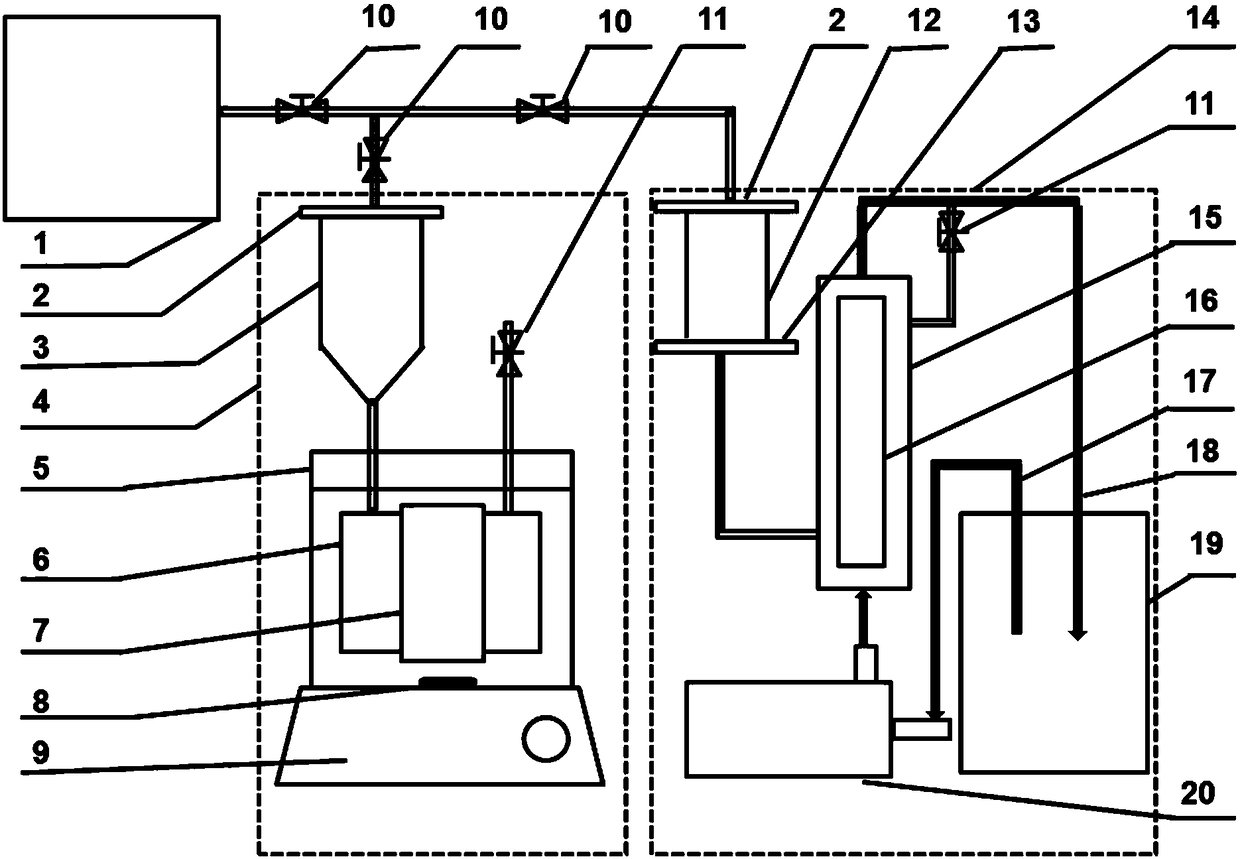

[0038] The invention provides a membrane emulsifier, such as figure 1 As shown, the equipment includes a stable pressure supply device 1 , a conventional membrane emulsification device 4 and a high flux membrane emulsification device 14 . The conventional membrane emulsification device 4 and the high-flux membrane emulsification device 14 are respectively connected to the stable pressure supply device 1 through double valves 10. The stable pressure supply device 1 is a liquid flow control pressure supply device. The stable pressure supply device 1 includes a flow meter, a dispersed phase Feeding device and constant flow pump.

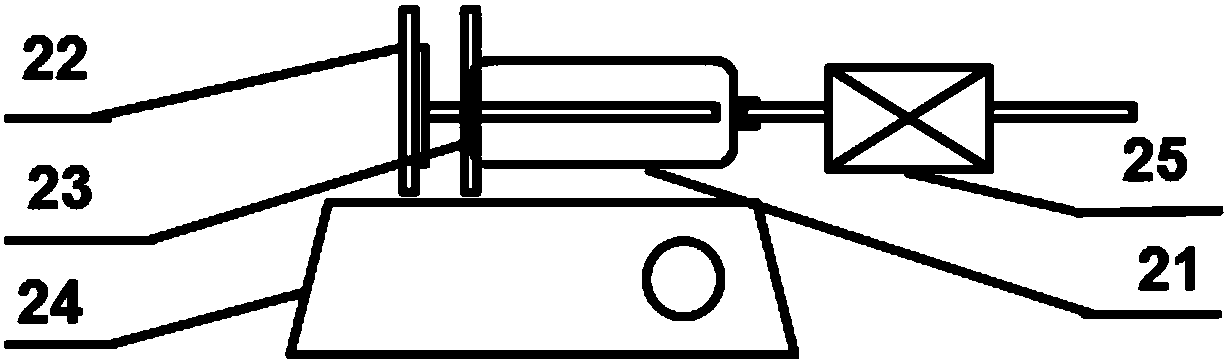

[0039] Among them, the stable pressure supply device 1 such as Figure 2a As shown, it includes a syringe pump 24, a dispersed-phase feeding device and a flowmeter 25 connected in sequence, the syringe pump is a single-channel syringe pump, the flowmeter is a differential pressure flowmeter, the dispersed-phase feeding device is a syringe 21, and the s...

Embodiment 2

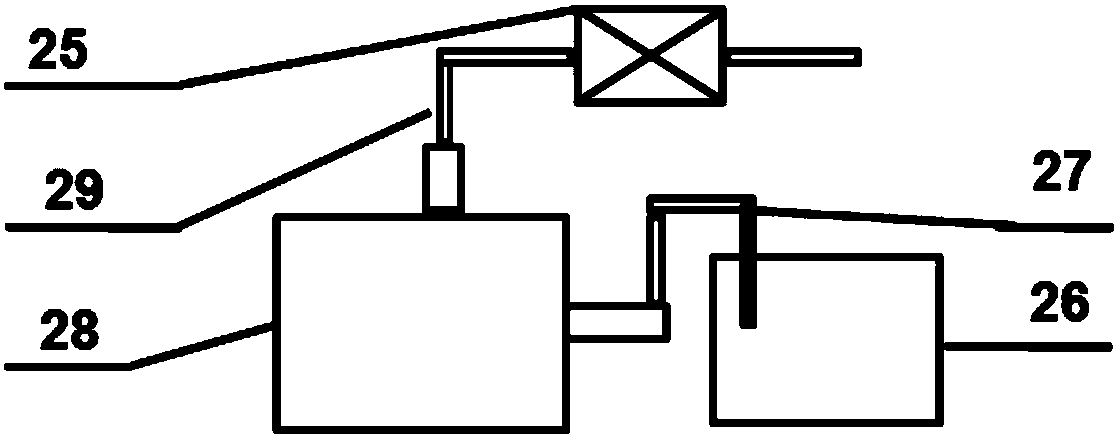

[0048] This embodiment provides a membrane emulsifier with stable pressure and easy operation. The structure is as described in Embodiment 1, the difference is that the stable pressure supply device 1 is Figure 2b As shown, it includes a flow meter 25 , a peristaltic pump 28 and a dispersed phase feeding device connected in sequence, and the dispersed phase feeding device is a beaker 26 . The flow meter 25 monitors the flow velocity of the dispersed phase in real time to ensure the stability of the dispersed phase flow, and the peristaltic pump 28 transports the dispersed phase to the The dispersed phase storage tank of the membrane emulsification device.

Embodiment 3

[0050] This embodiment provides a stable pressure and easy-to-operate membrane emulsifier, the structure of which is as described in Embodiment 1, except that the syringe pump is a multi-channel syringe pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com