Reactor vented waste gas purification device and method

An exhaust gas purification device and purification device technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve problems such as high investment and operation and maintenance costs, large safety hazards, poor stability, etc., to achieve equipment and operation Low maintenance cost, improved safety and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

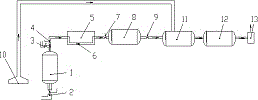

[0028] As shown in the figure, the present invention includes a reactor 1, a reactor discharge device 2, a vent waste gas bypass device 3, solenoid valves 4, 7, 9, a vent waste gas bypass device 5, a check valve 6, and an air bag collection chamber 8 , Workshop exhaust gas collection hood 10, large-scale exhaust gas dilution device 11, photolysis and oxidation device 12, fan 13. The top of the reaction kettle 1 is provided with a venting waste gas bypass device 3 , the bottom of the reaction kettle is provided with a reaction kettle discharge device 2 , and the venting waste gas check device 5 is provided with a check valve 6 . The reaction kettle 1 is connected to the air bag collection chamber 8 through the solenoid valve 4, the exhaust gas check device 5, and the solenoid valve 7. The air bag collection chamber 8 is connected to the large-scale waste gas dilution device through the solenoid valve 9 and the exhaust gas collection hood 10 of the workshop. 11. The air outlet o...

Embodiment 2

[0031] Because the light cracking oxidation device 12 can be changed into one or more in the plasma cracking oxidation device, ozone oxidation deodorization device, wet curtain type waste gas absorption and purification device, other purification devices, all the other are the same as embodiment 1, no longer here elaborate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com