Molybdenum-alloy disc-type flameproof motor seawater-desalination weld seam joint device

An explosion-proof motor and molybdenum alloy technology, applied in mechanical equipment, seawater treatment, electromechanical devices, etc., can solve the problems of high maintenance rate and affect production cost, and achieve the effect of reducing operating load, improving service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The structure and working principle of the present invention and the application in the reverse osmosis seawater desalination system are further elaborated in conjunction with the accompanying drawings and embodiments:

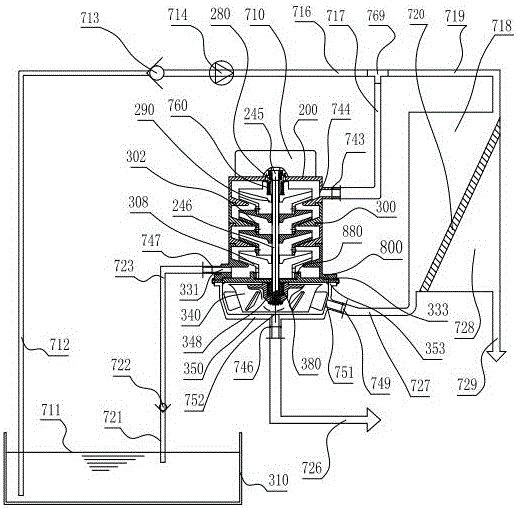

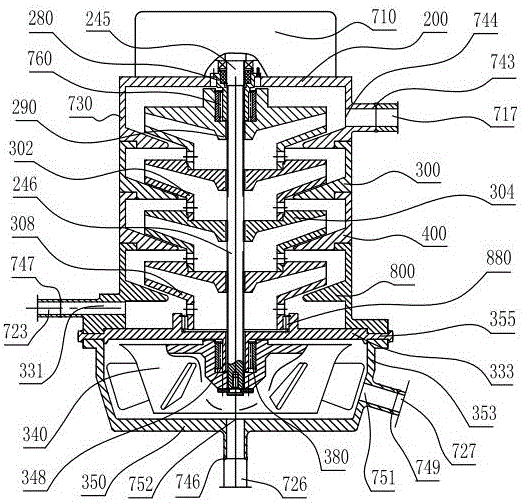

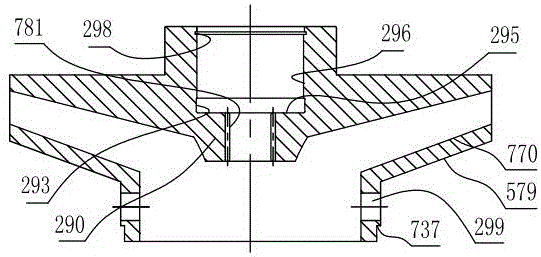

[0066] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 19 , Figure 24 with Figure 30 Among them, molybdenum alloy disc flameproof motor seawater desalination welding seam joint equipment, including seawater pretreatment tank 310, pretreatment seawater suction pipe 721, starting suction pipe 712, high-pressure starting pump 714, pipeline tee 769, reverse osmosis membrane 720 and welding Pressure exchange booster pump, the two sides of the reverse osmosis membrane 720 are the membrane water inlet chamber 718 and the membrane outlet chamber 728 respectively, and the welding pressure exchange booster pump has a booster welding seam joint 743, a pressure relief welding joint 746, and a suction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com