Device and method for treating organic industrial wastewater based on cavitation technique

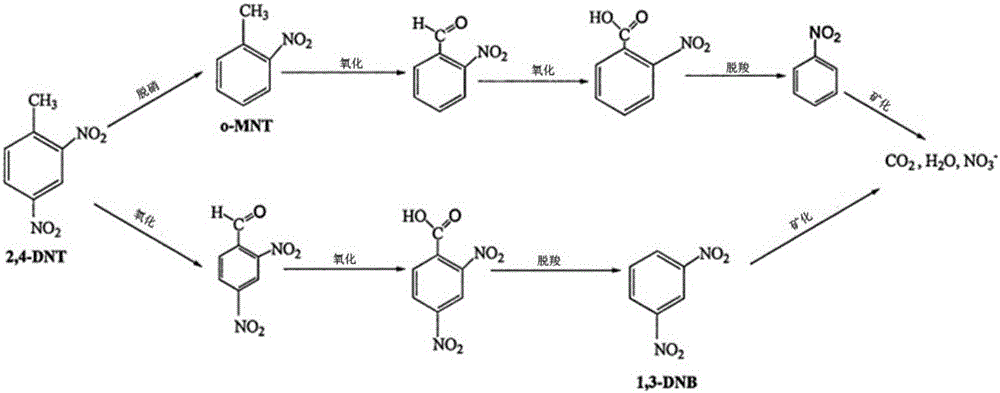

A waste water and cavitator technology, which is applied in the field of waste water equipment, can solve the problems of waste water pollution, DNT loss, etc., and achieve the effects of reducing sludge volume, improving digestion rate, and facilitating automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

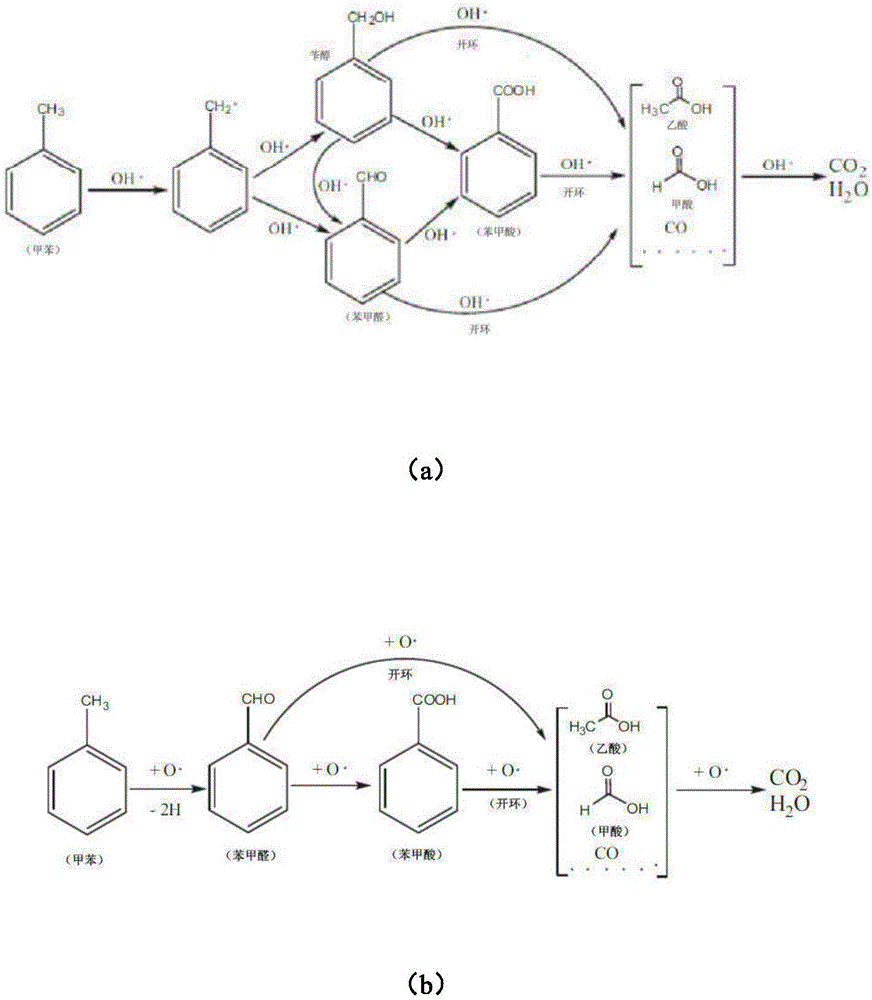

Method used

Image

Examples

Embodiment 1

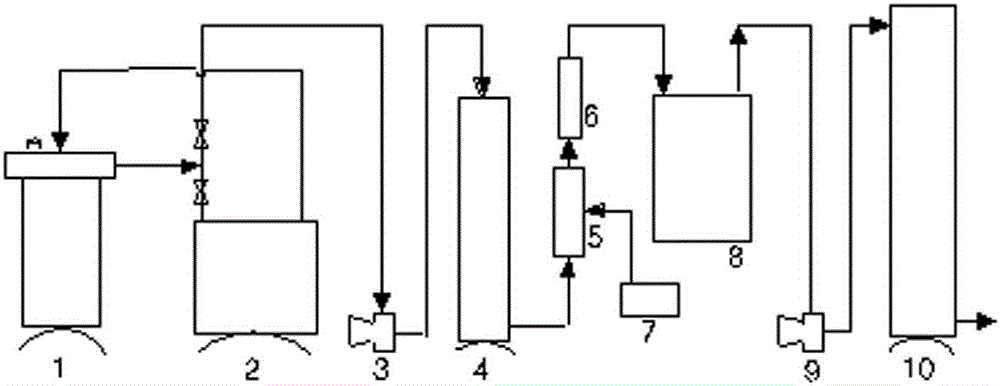

[0093] Example 1. Distilled water was premixed with 2,4-DNT to obtain 50 liters of sample water with a COD of 450 mg / l. Next add toluene at a rate of 10 mg per liter of water. A solution of DNT water and toluene was treated in a device in a loop comprising a rotary-pulse cavitator 1 , a centrifugal pump 2 , a membrane filter 4 , a hydrodynamic cavitator 5 , a UV lamp 6 and an ozone generator 7 . The processing time was 30 minutes. The measured COD of the effluent at the outlet of the device was 50 mg / l.

Embodiment 2

[0094] Example 2. Distilled water was premixed with 2,4-DNT to obtain 50 liters of sample water with a COD of 450 mg / l. Plant in a circuit comprising rotary-pulse cavitator 1, centrifugal pump 2, membrane filter 4, hydrodynamic cavitator 5, UV lamp 6 and ozone generator 7, carbon particle filter 8 and cyclone separator 10 Treat DNT water. The processing time was 30 minutes. The measured COD of the effluent at the output of the device was 10 mg / l.

Embodiment 3

[0095] Example 3. Distilled water was premixed with 2,4-TDA to obtain 50 liters of sample water with a COD of 450 mg / l. Plant in a circuit comprising rotary-pulse cavitator 1, centrifugal pump 2, membrane filter 4, hydrodynamic cavitator 5, UV lamp 6 and ozone generator 7, carbon particle filter 8 and cyclone separator 10 Treat TDA water. The processing time was 30 minutes. The measured COD of the effluent at the output of the device was 10 mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com