Ceramic preparation method, ceramic and basalt wire-drawing bushing

A technology of ceramic preparation and basalt, which is applied in the field of material manufacturing, can solve the problems of high production cost, failure to meet the high requirements of high temperature resistance, electrical conductivity and strength, etc., and achieve the effect of reducing production cost, high strength and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

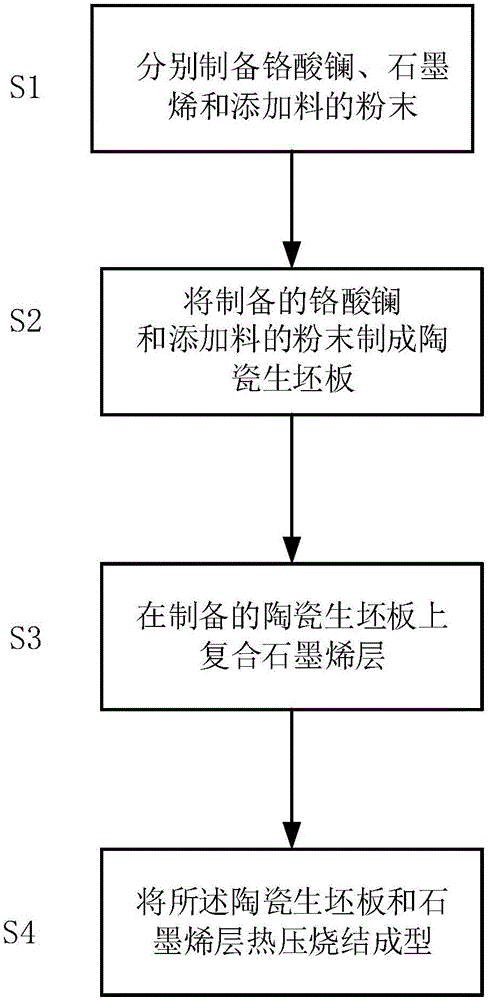

[0043] S1), respectively prepare the powders of lanthanum chromate, graphene and additives.

[0044] In this step, first select high-purity various raw materials, including lanthanum chromate, graphene and additives, requiring the purity of various raw materials to be ≥ 98%, preferably 99.80-99.99%, in order to strictly control the composition ratio;

[0045] Then, various components of lanthanum chromate, graphene and additives are put into a ball mill for continuous pulverization to make superfine powder. Preferably, the ultrafine powder has a particle diameter of 5-25 μm, more preferably 1-3 μm, which can make the texture of the prepared ceramic more uniform.

[0046] S2), making the powder of the prepared lanthanum chromate and additives into a ceramic green body plate.

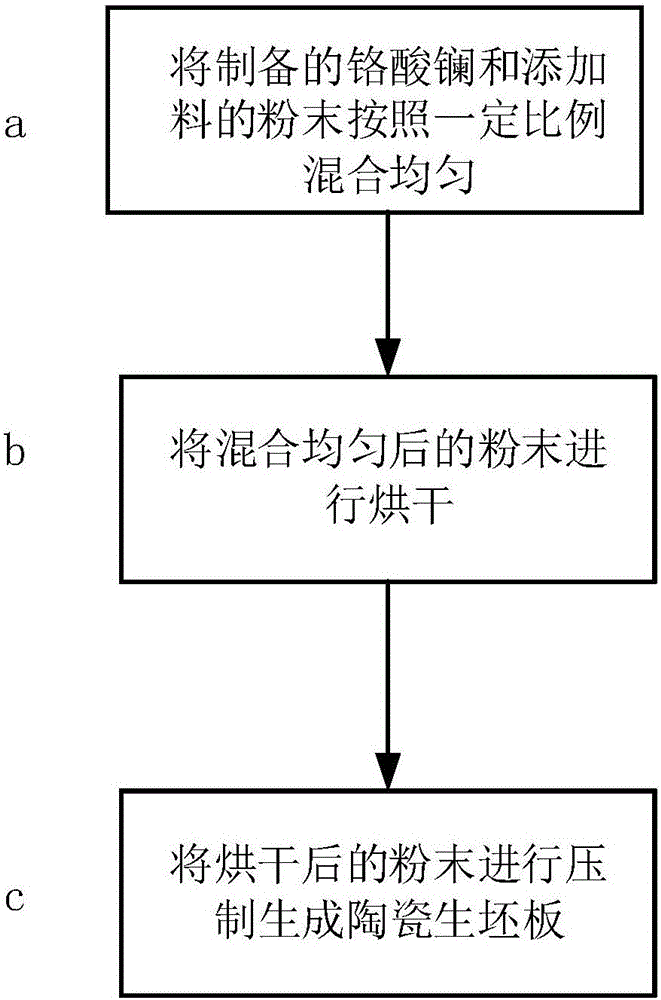

[0047] refer to figure 2 , in this step, the following specific steps are included:

[0048] a), dope the powder of lanthanum chromate and additive powder prepared in step S1) according to the parts b...

Embodiment 2

[0057] S1), respectively prepare the powders of lanthanum chromate, graphene and additives.

[0058] In this step, first select high-purity various raw materials, including lanthanum chromate, graphene and additives, requiring the purity of various raw materials to be ≥ 98%, preferably 99.80-99.99%, in order to strictly control the composition ratio;

[0059]Then, various components of lanthanum chromate, graphene and additives are put into a ball mill for continuous pulverization to make superfine powder. Preferably, the ultrafine powder has a particle diameter of 5-25 μm, more preferably 1-3 μm, which can make the texture of the prepared ceramic more uniform.

[0060] S2), making the powder of the prepared lanthanum chromate and additives into a ceramic green body plate.

[0061] refer to figure 2 , in this step, the following specific steps are included:

[0062] a), the lanthanum chromate prepared in step S1) and the powder of the additive are doped and mixed uniformly...

Embodiment 3

[0071] S1), respectively prepare the powders of lanthanum chromate, graphene and additives.

[0072] In this step, first select high-purity various raw materials, including lanthanum chromate, graphene and additives, requiring the purity of various raw materials to be ≥ 98%, preferably 99.80-99.99%, in order to strictly control the composition ratio;

[0073] Then, various components of lanthanum chromate, graphene and additives are put into a ball mill for continuous pulverization to make superfine powder. Preferably, the ultrafine powder has a particle diameter of 5-25 μm, more preferably 1-3 μm, which can make the texture of the prepared ceramic more uniform.

[0074] S2), making the powder of the prepared lanthanum chromate and additives into a ceramic green body plate.

[0075] refer to figure 2 , in this step, the following specific steps are included:

[0076] a), dope the powder of lanthanum chromate and additive powder prepared in step S1) according to the parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com