Light-absorbing antidazzle hard coating film, and preparation method and application thereof

A light-absorbing, hard-coating technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as whitening and glare, and achieve the effect of improving picture quality, excellent anti-glare performance, and preventing whitening and glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

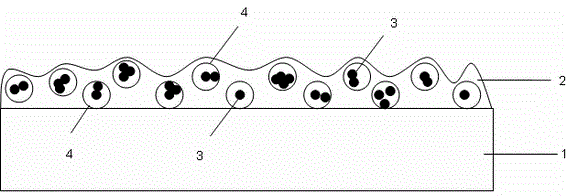

Image

Examples

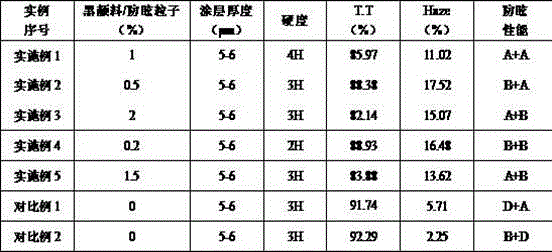

Embodiment 1

[0045] Preparation of light-absorbing anti-glare microparticles: 5 g of monodispersed polymethyl methacrylate (PMMA) particles (micron, selected from Sekisui Synthetic Co., Ltd., Japan) with an average particle size of 5 μm were dissolved in 10 g of a swelling agent ( ethyl acetate, commercially available), then add 0.05g of nano-carbon black (N220, product of Cabot Company in the United States), and fully swell at 50°C for 3h in a 40KHZ frequency, sinusoidal signal ultrasonic wave, and the swollen mixture is vacuumized Filtration and washing with absolute ethanol were carried out for 3 times, and the filter cake was vacuum-dried at 80 °C for 4-5 h to obtain light-absorbing anti-glare particles coated with 1% by mass of carbon black.

[0046] 25 parts by weight of urethane acrylate

[0047] Dipentaerythritol penta / hexaacrylate 20 parts by weight

[0048] Light-absorbing anti-glare particles 5 parts by weight

[0049] Irgacure 184 4 parts by weight

[0050] Butyl acetate 45 ...

Embodiment 2

[0055] Preparation of light-absorbing anti-glare microparticles: Dissolve 5 g by weight of monodisperse polystyrene (PS) particles (micron, Soken Chemical) with an average particle size of 6 μm in 20 g by weight of a swelling agent (cyclohexane, commercially available) Then add 0.025g of nano-carbon black (N339, product of Cabot Company in the United States), and fully swell at 50 ℃ for 3h in 40KHZ frequency, sinusoidal signal ultrasonic wave, and the swollen mixture is vacuum filtered and washed with absolute ethanol for 3 hours. Second, the filter cake was vacuum-dried at 80 °C for 4-5 h to obtain light-absorbing anti-glare particles coated with 0.5% by mass of carbon black.

[0056] 20 parts by weight of urethane acrylate

[0057] Pentaerythritol triacrylate (PETA) 15 parts by weight

[0058] Light-absorbing anti-glare particles 10 parts by weight

[0059] Irgacure 184 6 parts by weight

[0060] Toluene 47 parts by weight

[0061] BYK-UV3570 2 parts by weight

[0062] ...

Embodiment 3

[0065] Preparation of light-absorbing anti-glare microparticles: Dissolve 5 g of monodispersed polymethyl methacrylate particles with an average particle size of 3 μm (micron scale, selected from Sekisui Synthetic Co., Ltd.) in 30 g of a swelling agent (butanone, Commercially available), then add 0.1g of nano-graphite (S-1, Qingdao Chenyang Graphite Co., Ltd.), and fully swell at 50°C for 3h at 40KHZ frequency and sinusoidal signal ultrasonic wave, and filter the swollen mixture by vacuum. After washing with absolute ethanol for 3 times, the filter cake was vacuum-dried at 80 °C for 4-5 h to obtain light-absorbing anti-glare particles wrapped with 2% by mass of graphite.

[0066] 30 parts by weight of urethane acrylate

[0067] Pentaerythritol tetraacrylate 15 parts by weight

[0068] Light-absorbing anti-glare particles 6 parts by weight

[0069] Darocur1173 8 parts by weight

[0070] Butyl acetate 40 parts by weight

[0071] BYK-361 1 part by weight

[0072] Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com