Instant-sealing silicone sealant and preparation method thereof

A technology of silicone glue and base silane, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reducing the production and assembly efficiency of mechanical parts, affecting the production continuity, etc., and achieving excellent affinity , save process, improve the effect of thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

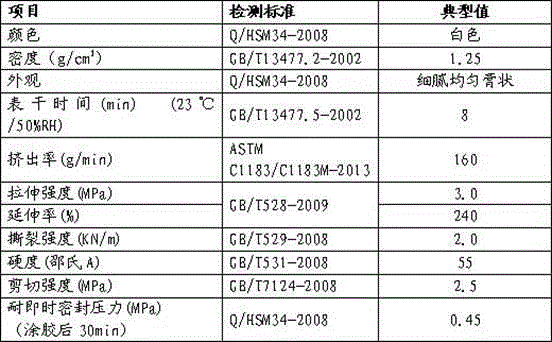

Image

Examples

Embodiment 1

[0025] An instant sealing silicone glue, which is composed of the following components in weight percentage: 29.5% hydroxyl-terminated polydimethylsiloxane (20000cp viscosity), 21% hydroxyl-terminated polydimethylsiloxane (3000cp viscosity), 38.5% nano-calcium carbonate, 5.4% methyl tributylketoxime silane, 1.0% vinyl tributylketoxime silane, 4.45% meteorological silica, 0.05% hexamethyl Disilazane, 0.05% of dibutyltin dilaurate and 0.05% of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0026] The preparation method is as follows, based on the percentage of the total weight of the instant sealing silicone glue to be prepared:

[0027] (1) Add 29.5% hydroxyl-terminated polydimethylsiloxane (20000cp) and 21%% hydroxyl-terminated polydimethylsiloxane (3000cp) into the reactor, heat up to 110°C and stir in vacuum for 3 hours;

[0028] (2) Cool down to below 50°C, put 38.5% nano-calcium carbonate into the reactor, and stir in vacuum for 40 minutes;

[0029] (3) Continue to co...

Embodiment 2

[0035] An instant sealing silicone glue, which is composed of the following components in weight percentage: 31.5% hydroxyl-terminated polydimethylsiloxane (20000cp viscosity), 21% hydroxyl-terminated polydimethylsiloxane (3000cp viscosity), 36.5% nano-calcium carbonate, 4.6% methyl tributylketoxime silane, 2.0% vinyl tributylketoxime silane, 4.25% meteorological silica, 0.05% hexamethyl Disilazane, 0.04% of dibutyltin dilaurate and 0.06% of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0036] The preparation method is as follows, based on the percentage of the total weight of the instant sealing silicone glue to be prepared:

[0037] (1) Add 31.5% hydroxyl-terminated polydimethylsiloxane (20000cp) and 21% hydroxyl-terminated polydimethylsiloxane (3000cp) to the reactor, heat up to 110°C and stir in vacuum for 3 hours;

[0038] (2) Cool down to below 50°C, put 36.5% nano-calcium carbonate into the reactor, and stir in vacuum for 40 minutes;

[0039] (3) Continue to cool ...

Embodiment 3

[0042] An instant sealing silicone glue, which is composed of the following components in weight percentage: 28% hydroxyl-terminated polydimethylsiloxane (20000cp viscosity), 23.5% hydroxyl-terminated polydimethylsiloxane (3000cp viscosity), 39.2% nanometer calcium carbonate, 4.5% methyl tributylketoxime silane, 1.0% vinyl tributylketoxime silane, 3.65% meteorological silica, 0.05% hexamethyl Disilazane, 0.04% of dibutyltin dilaurate and 0.05% of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane.

[0043] The preparation method is as follows, based on the percentage of the total weight of the instant sealing silicone glue to be prepared:

[0044] (1) Add 32% hydroxyl-terminated polydimethylsiloxane (20000cp) and 23.5% hydroxyl-terminated polydimethylsiloxane (3000cp) into the reactor, heat up to 110°C and stir in vacuum for 3 hours;

[0045] (2) Cool down to below 50°C, put 39.2% nano-calcium carbonate into the reactor, and stir in vacuum for 40 minutes;

[0046] (3) Continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com