Thermal control Bridgman method single crystal growth device and method for fluoride single crystals

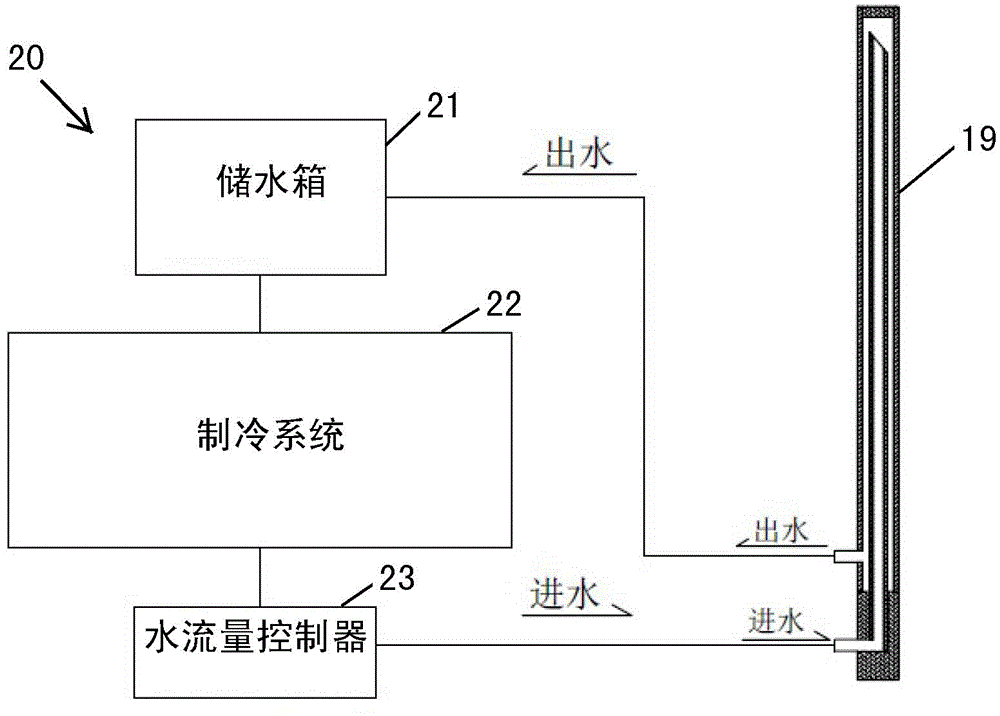

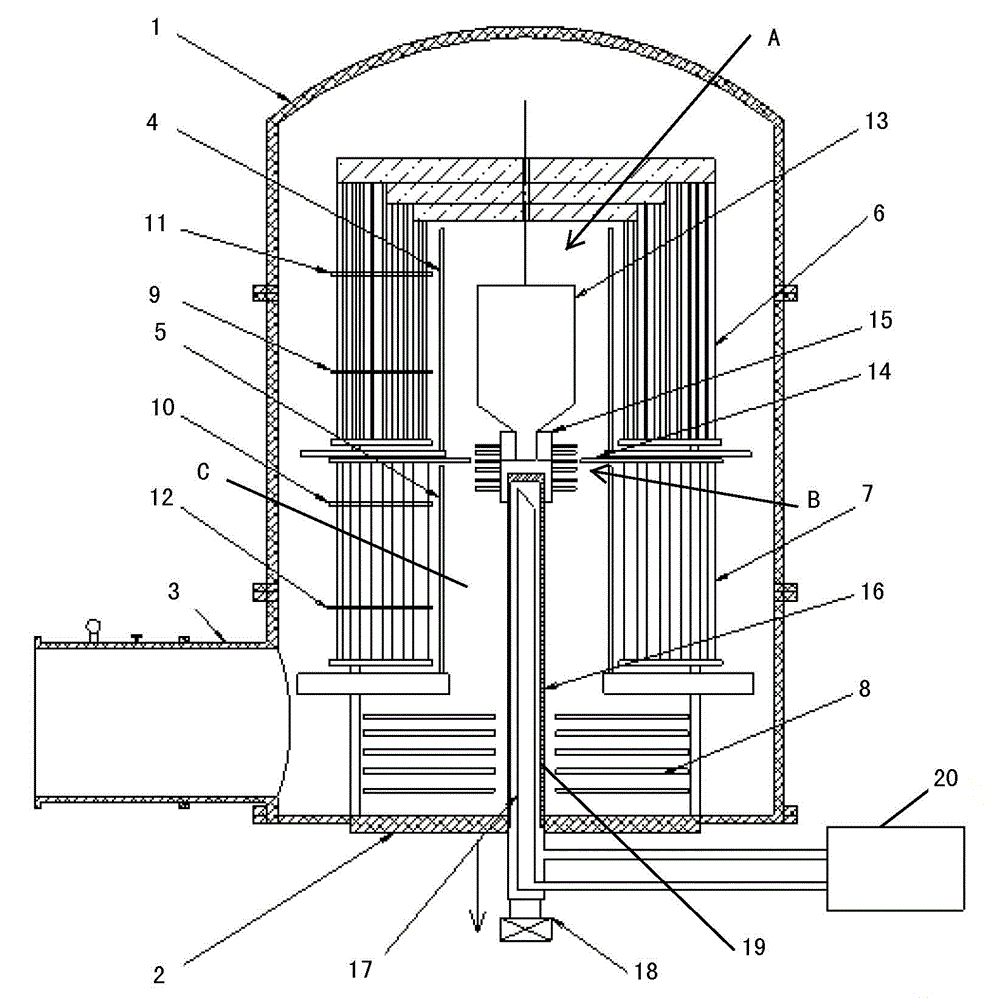

A growth device and single crystal technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unstable solid-liquid interface and difficulty in releasing latent heat of crystallization, so as to avoid the phenomenon of easy polycrystalline growth and strengthen the seed crystal Heat conduction effect, effect of enhancing water cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] growCaF 2 Single crystal, the specific preparation method is as follows:

[0050] 8Kg CaF 2 Crystal feedstock and 80g PbF 2 The powder is evenly mixed and loaded with CaF at the bottom 2 In the crucible 13 made of graphite of the crystal seed crystal, the crucible 13 is then fixed on the zirconia bracket 15 on the crucible water-cooled support column 19 inside the furnace chamber 1, wherein the PbF 2 as an oxygen scavenger. Raise the crucible 13 to an appropriate position in the high temperature zone A (the upper surface of the seed crystal is slightly higher than the heat shield 14), close the furnace chamber 1 and start vacuuming, when the vacuum degree is ≤5*10 -3 After pa, start to raise the temperature of the chemical material at a rate of 50°C / h; when the temperature of the monitoring thermocouple at the seed crystal reaches 800°C, keep the temperature for 10 hours to fully remove the oxygen component inside the crucible 13 . Then continue to heat up at a rat...

Embodiment 2

[0052] Growth of Yb,Na:CaF 2 Single crystal, the specific preparation method is as follows:

[0053] 6 Kg Yb, Na co-doped CaF 2 Crystal feedstock and 60g PbF 2 The powder is evenly mixed and loaded with CaF at the bottom 2 In the crucible 13 made of graphite of the crystal seed crystal, the crucible 13 is then fixed on the zirconia bracket 15 on the crucible water-cooled support column 19 inside the furnace chamber 1, wherein the PbF 2 as an oxygen scavenger. Raise the crucible 13 to an appropriate position in the high temperature zone A (the upper surface of the seed crystal is slightly higher than the heat shield 14), close the furnace chamber 1 and start vacuuming, when the vacuum degree is ≤5*10 -3 After pa, start to raise the temperature of the chemical material at a rate of 50°C / h; when the temperature of the monitoring thermocouple at the seed crystal reaches 800°C, keep the temperature for 10 hours to fully remove the oxygen component inside the crucible 13 . Then...

Embodiment 3

[0055] growSrF 2 Single crystal, the specific preparation method is as follows:

[0056] 8Kg SrF 2 Crystal feedstock and 80g PbF 2 The powder is evenly mixed and loaded with SrF at the bottom 2 In the crucible 13 made of graphite of the crystal seed crystal, the crucible 13 is then fixed on the zirconia bracket 15 on the crucible water-cooled support column 19 inside the furnace chamber 1, wherein the PbF 2 as an oxygen scavenger. Raise the crucible 13 to an appropriate position in the high temperature zone A (the upper surface of the seed crystal is slightly higher than the heat shield 14), close the furnace chamber 1 and start vacuuming, when the vacuum degree is ≤5*10 -3 After pa, start to raise the temperature of the chemical material at a rate of 50°C / h; when the temperature of the monitoring thermocouple at the seed crystal reaches 800°C, keep the temperature for 10 hours to fully remove the oxygen component inside the crucible 13 . Then continue to heat up at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com