Ground driving device with hydraulic, speed-limiting and temperature-control reverse rotation preventing function

A driving device, anti-reverse technology, applied to pump devices, brake types, machines/engines, etc., can solve problems such as accidents, effect decline, personal accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

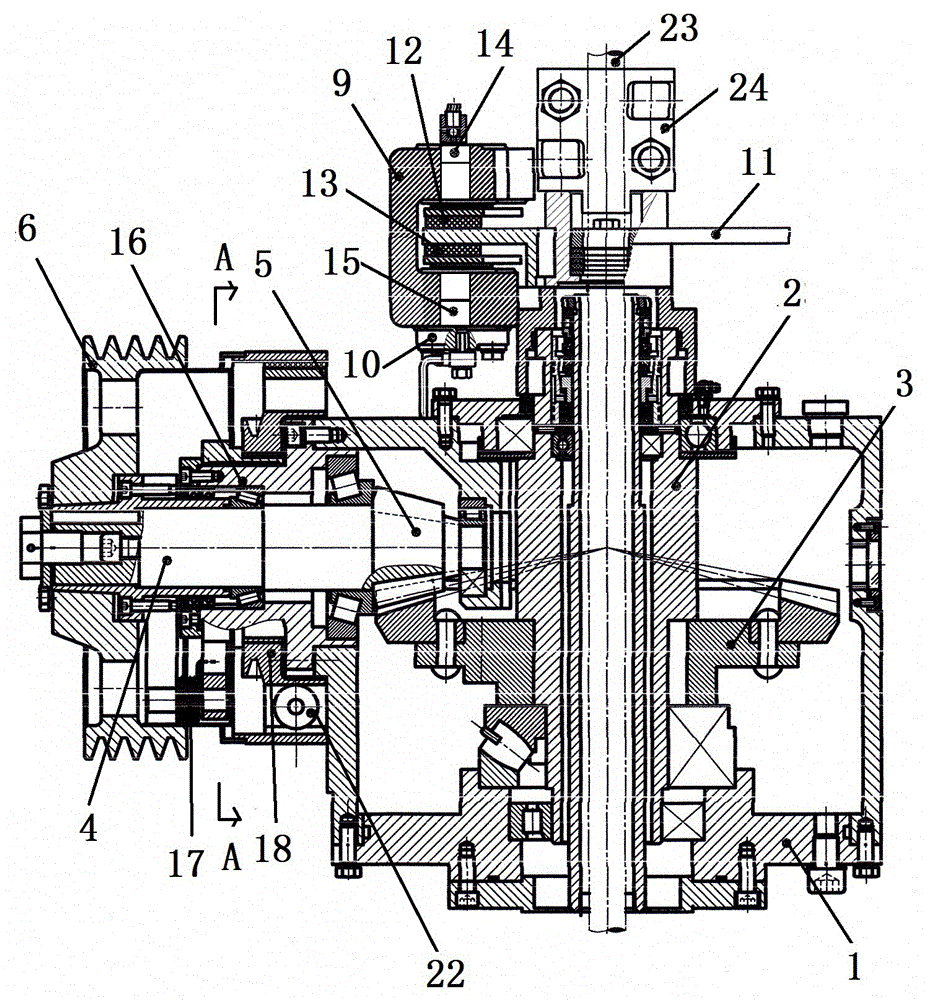

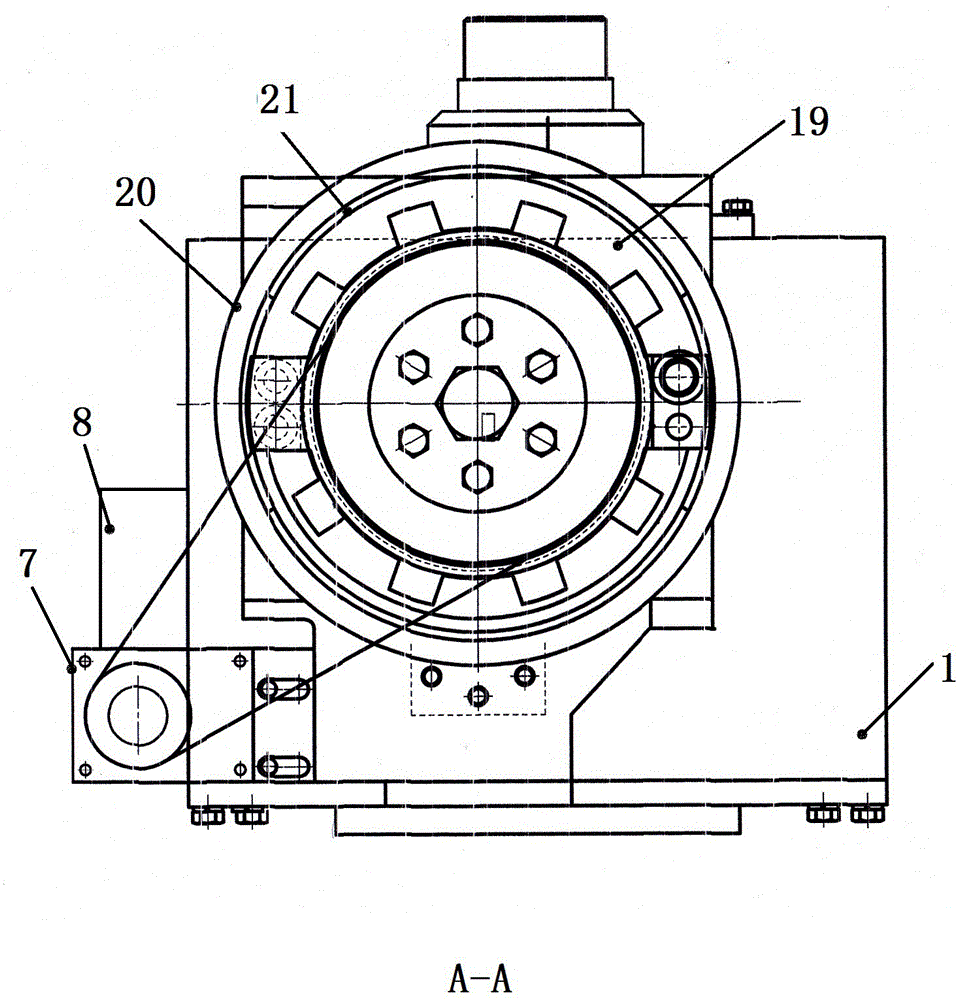

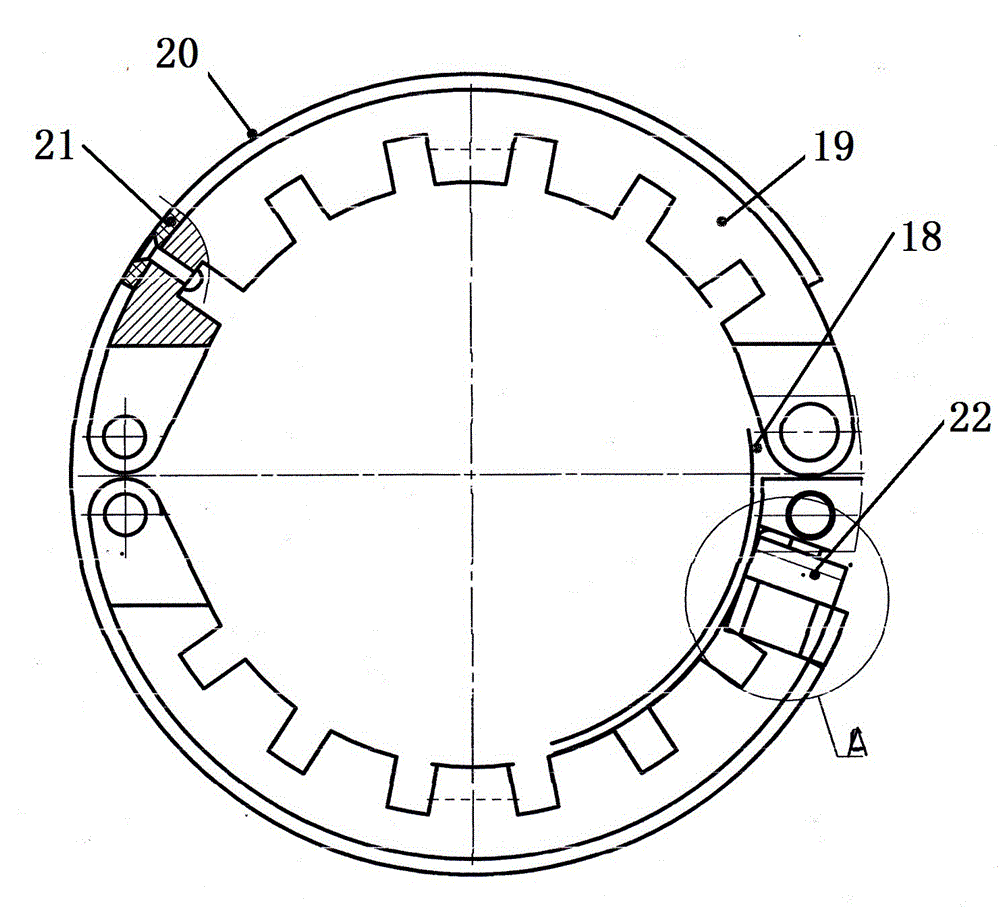

[0011] refer to figure 1 —4, it includes reduction box 1, and vertical shaft 2 is contained in the reduction box, and gear 3 is arranged on the vertical shaft, and bevel gear 5 is arranged on the main shaft 4 that stretches into the reduction box, and the bevel gear on the main shaft and the gear on the vertical shaft meshing, there is a large pulley 6 on the main shaft, the gear pump 7 is installed on the pump seat on the reduction box, the hydraulic oil tank 8 is installed on the top of the gear pump, the oil outlet of the hydraulic oil tank is connected with the oil inlet of the gear pump, and the gear pump The oil outlet has an oil pipe connected to the oil inlet of the brake caliper 9, the brake caliper is fixed on the brake seat 10, the brake seat is fixed on the upper cover of the reduction box, the brake disc 11 is installed on the top of the vertical shaft, and the brake There is an upper friction block 12 above the disc, and a lower friction block 13 below the brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com