Machine-vision-based device and method for measuring vibration of flexible double-joint mechanical arm

A flexible robotic arm and machine vision technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of slow measurement speed, cumbersome calculation process, complex structure, etc., without changing the vibration characteristics , strong anti-interference characteristics, and the effect of simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The invention adopts the method of machine vision to realize the device and method of low-frequency mode analysis by collecting the vibration displacement of the light source at the tail end of the mechanical arm at different moving positions.

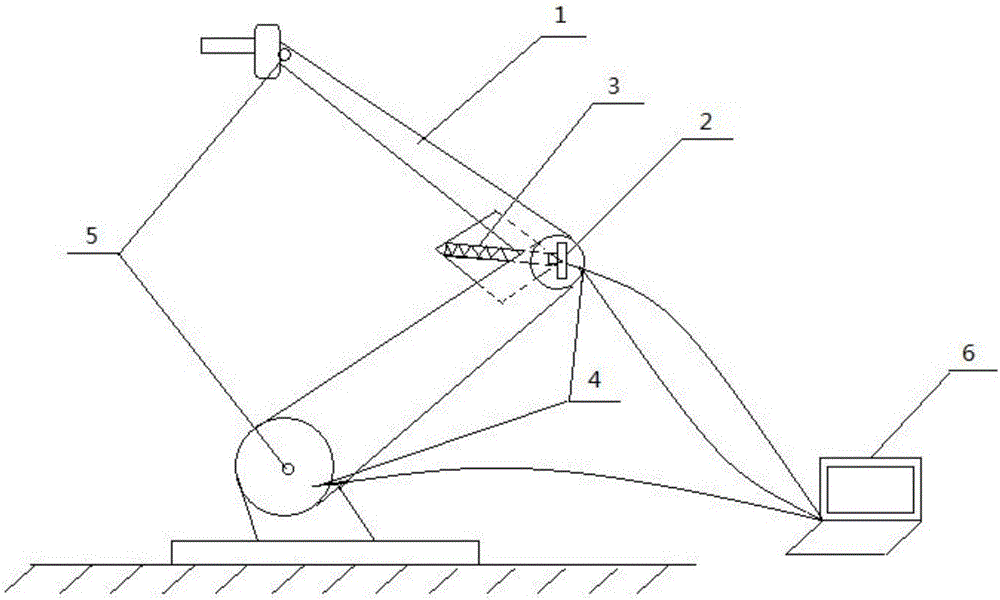

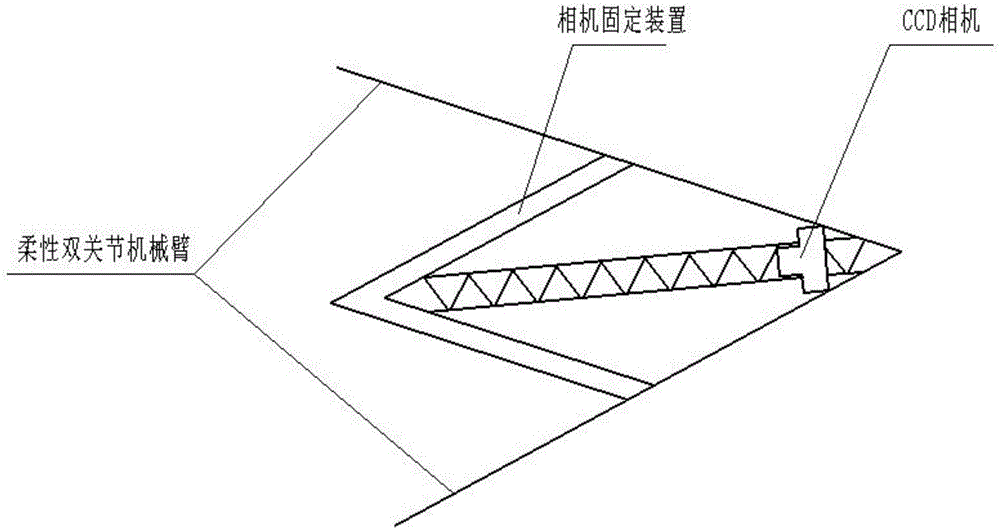

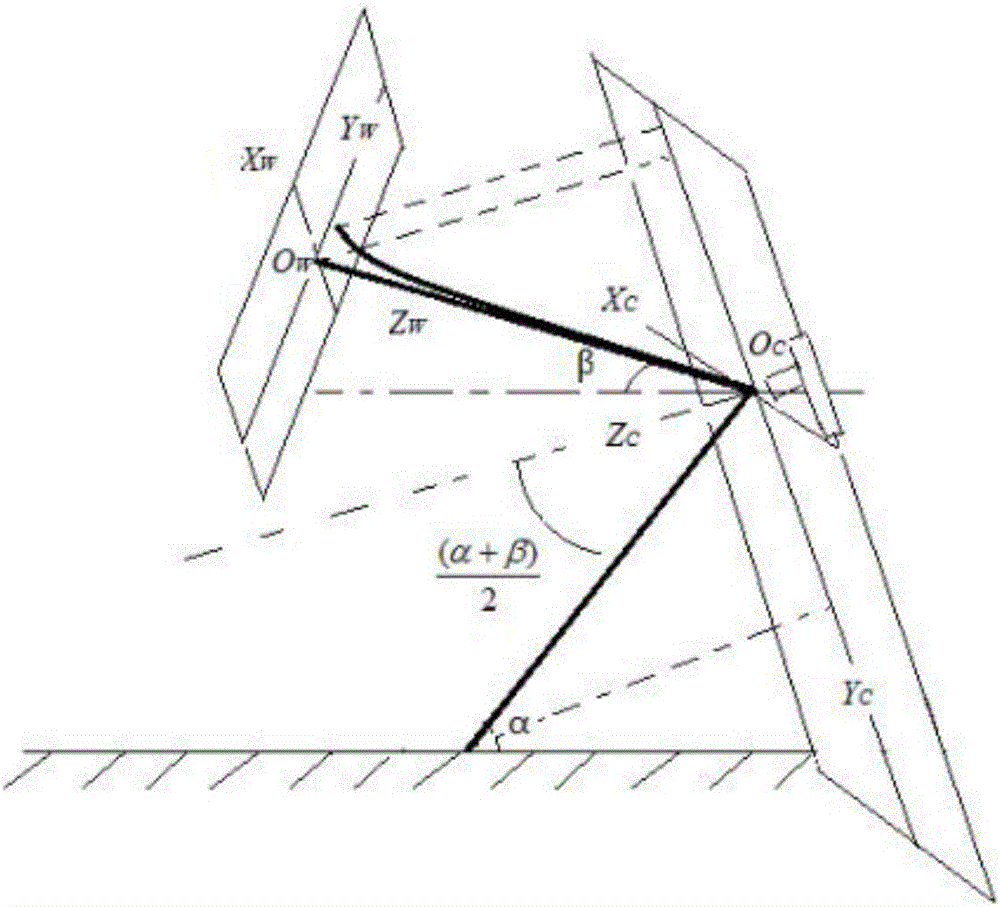

[0020] Such as figure 1 As shown, the measurement device for the vibration of the flexible double-joint manipulator based on machine vision includes a double-joint flexible manipulator 1, a CCD camera 2, a camera fixing device 3, an absolute encoder 4, a plurality of LED light-emitting tubes 5 and a PC 6; In the flexible double-joint mechanical arm 1, an absolute value encoder 4 is installed on the rotating motor of the arm lever of the two joints, and the output end of the encoder is connected to a PC 6, and the LED light-emitting tube 5 is placed on two sides of the double-joint flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com