Reverse-flow type rapid extraction device for sediment organic matter

An extraction device and organic matter technology, applied in the field of environmental research, can solve problems such as long time, high equipment requirements, and high processing costs, and achieve the effects of easy temperature, high extraction efficiency, and temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

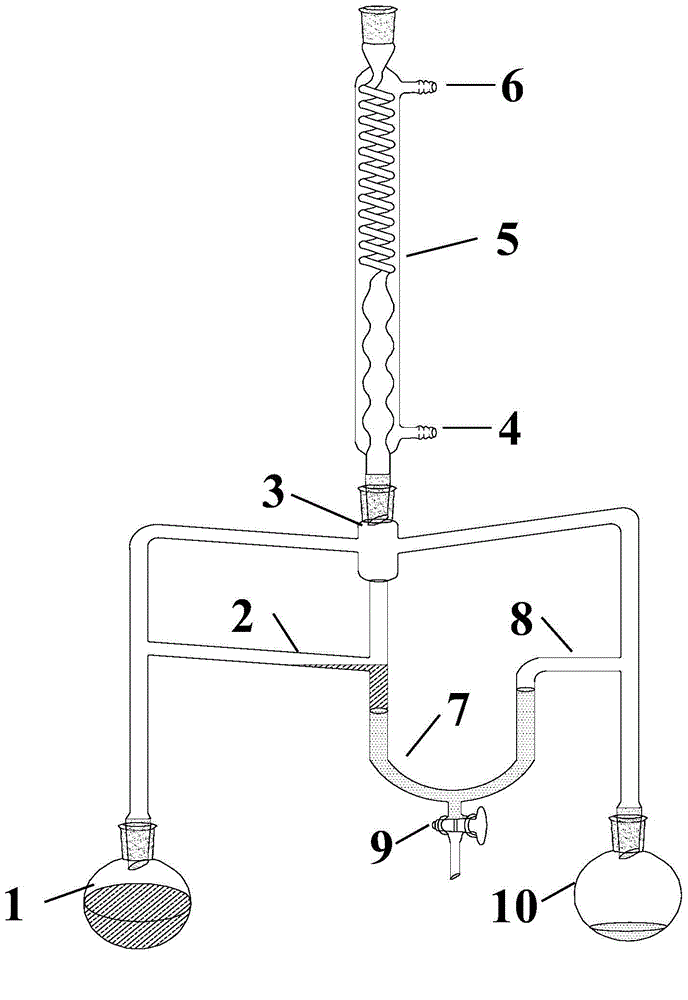

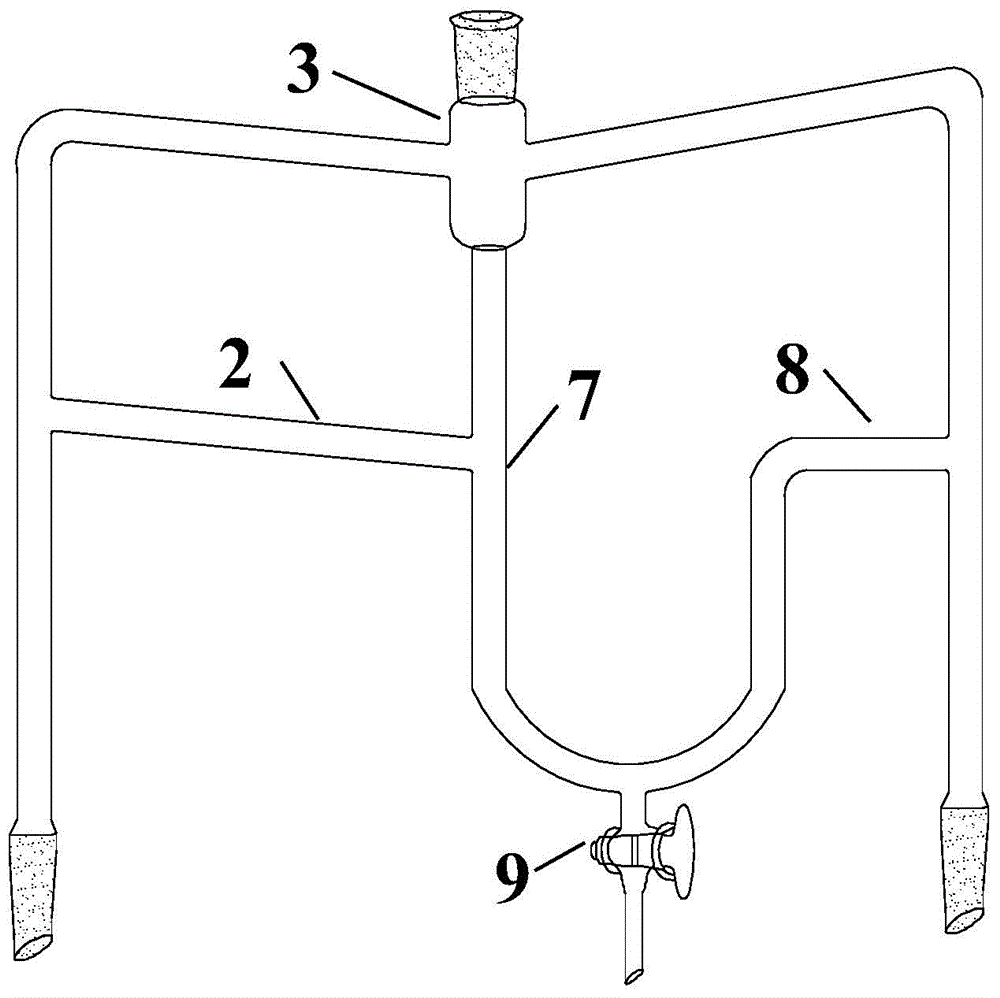

[0016] 1. If Figure 4 As shown, add 2g of 100-mesh sediment sample and 200mL ultrapure water (TOC<1ppb) to round-bottom flask 1, and add 15mL of organic extraction solvent to round-bottom flask 10.

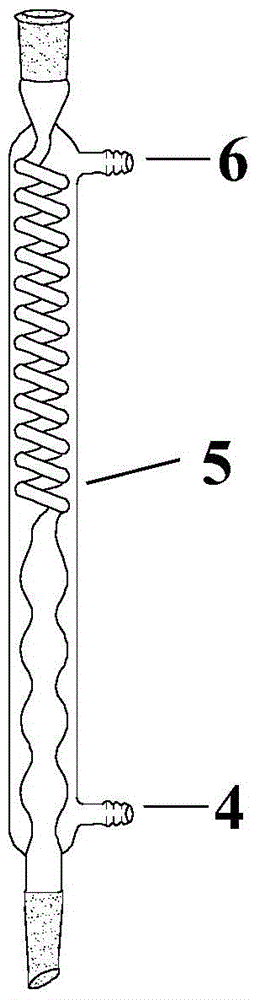

[0017] 2. If figure 1 As shown, the round-bottom flasks 1 and 10 are respectively connected to the left and right frosted ports at the lower end of the reflux collection system, and the frosted port at the lower end of the serpentine spherical integrated condenser 5 is connected to the upper end of the reflux collection system. 4 of the condensing pipe 5 is connected to the circulating cooling water inlet pipe, and 6 is connected to the circulating cooling water outlet pipe; the outer pipe wall of the serpentine spherical integrated condensing pipe 5 is clamped by an iron stand to fix the whole device, and the whole device is kept vertical. straight.

[0018] 3. Turn on the circulating cooling water, use the electric heating mantle to heat the round-bottom flask 1 and the round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com