All-digital intelligent control and detection system for crimping twisting wetting machine

A detection system and intelligent control technology, which is applied in the field of twisted wire, fully automatic integration of wire harness production, automatic control and quality inspection of tin dipping process, wire harness crimping terminal, can solve low production efficiency, unreasonable design, and product quality detection accuracy Insufficient and other problems, to achieve the effect of improving efficiency, improving the level of automation, and increasing the number of detection items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

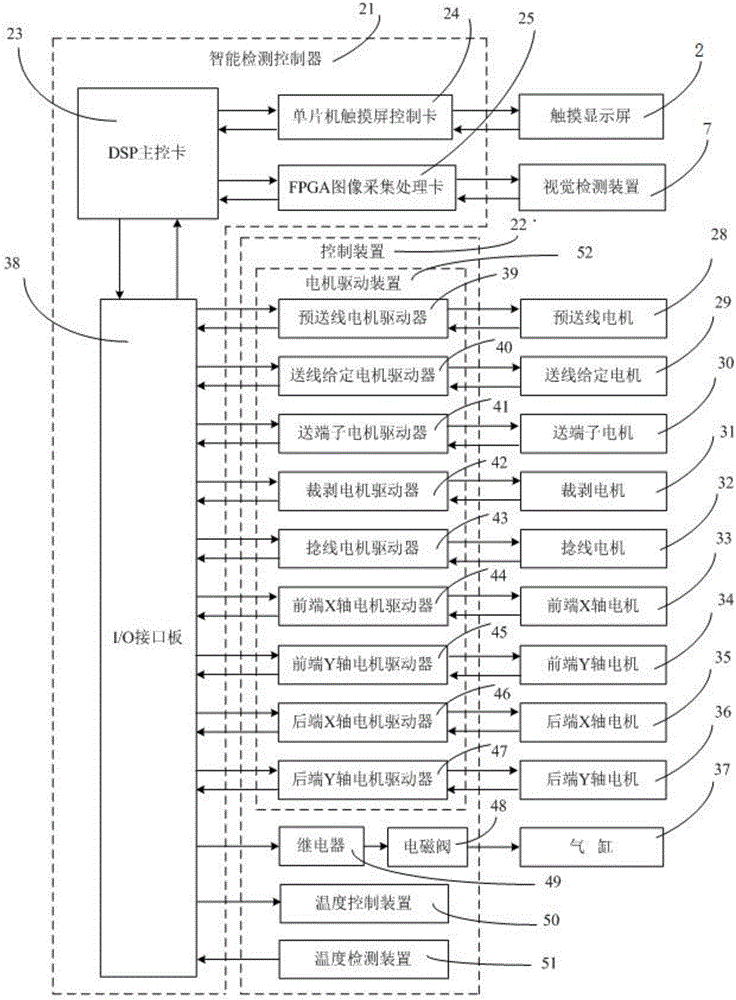

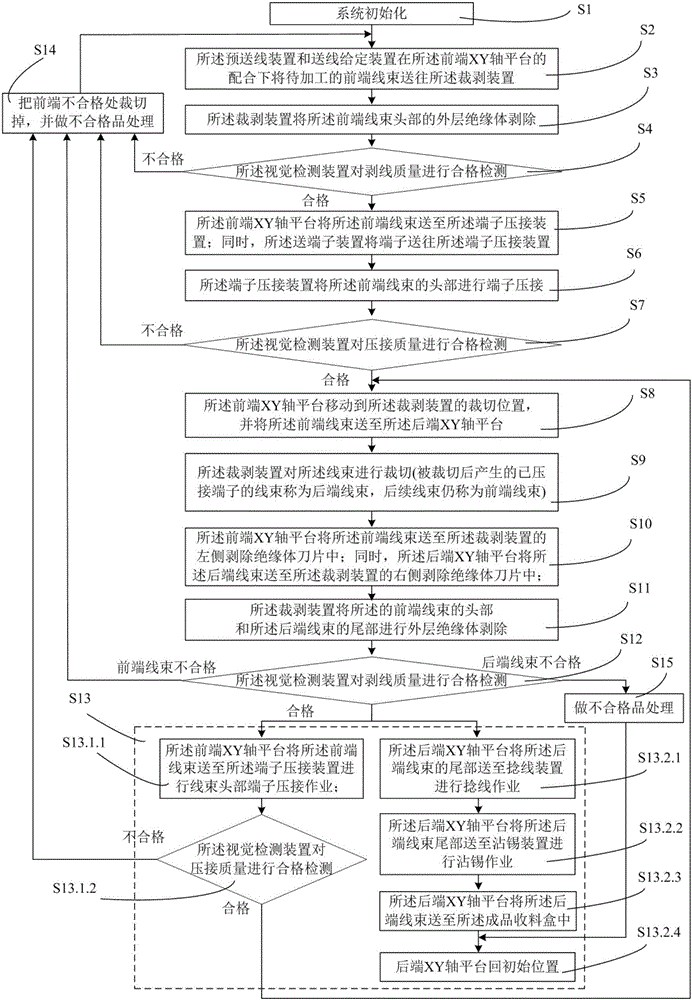

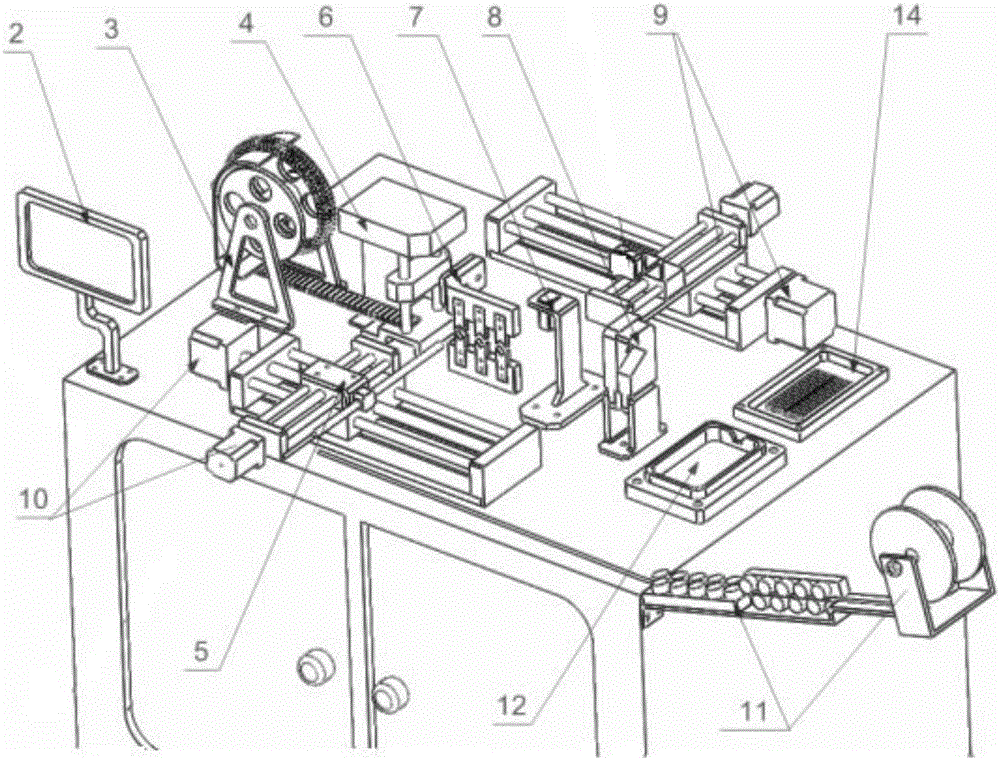

[0069] Such as Figure 1-4As shown, the system and equipment are initialized, and then the equipment is set up on the touch screen 2, and the single-chip touch screen control card 24 sends the set signal to the DSP main control card 23 in the intelligent detection controller 21, and the equipment begins to start. , the DSP main control card 23 transmits the signal to the control device 22 through the I / O interface board 38 .

[0070] After the motor drive device 52 receives the signal, the equipment starts to run. The pre-feeding wire motor driver 39 drives the pre-feeding wire motor 28 after receiving the signal, so that the pre-feeding mechanism 11 will regulate and straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com