Grid mesh and ionic source

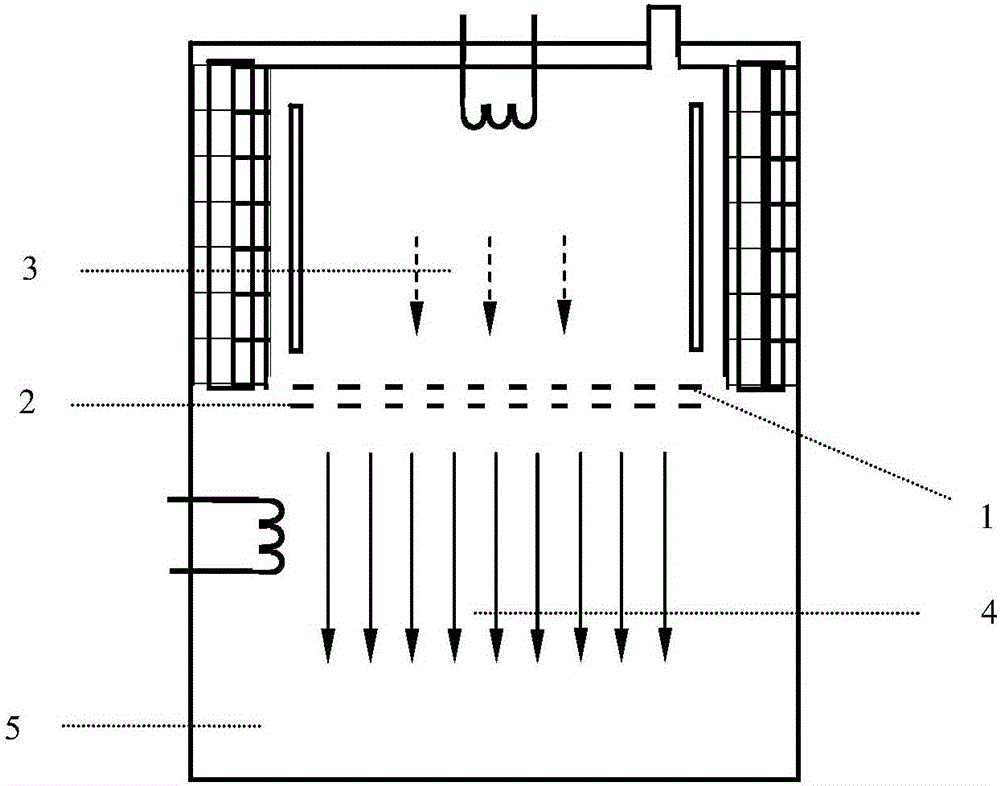

A technology of ion source and grid, which is applied in the field of ion source, can solve the problems of easy thermal deformation of the grid, achieve the effect of improving repeatability, solving thermal deformation problems, and maintaining uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

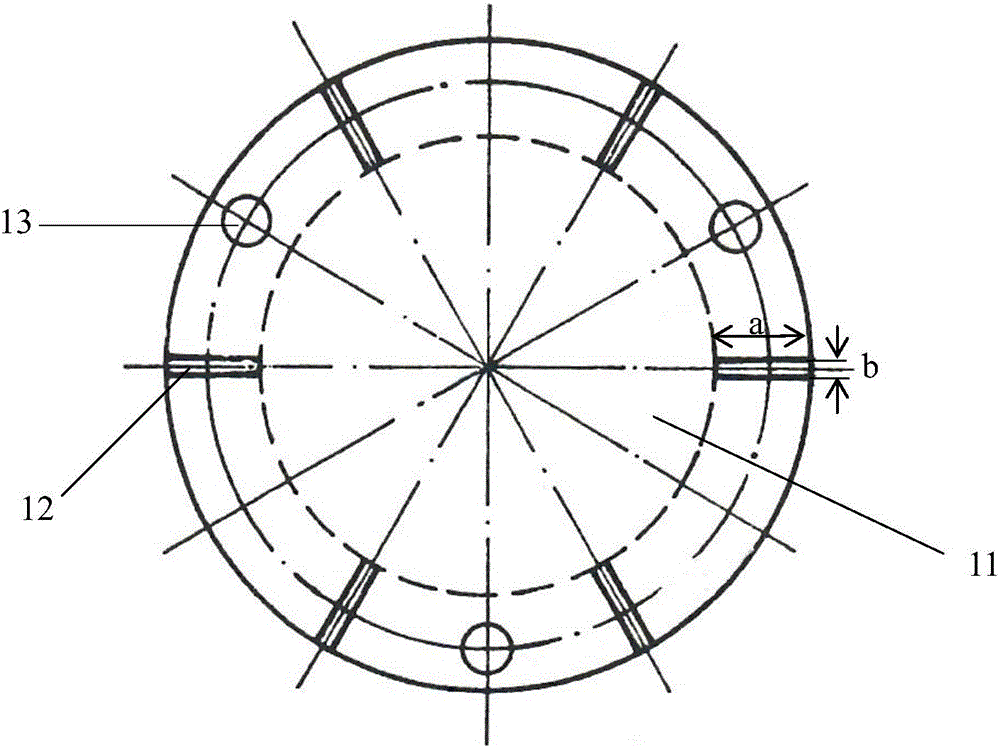

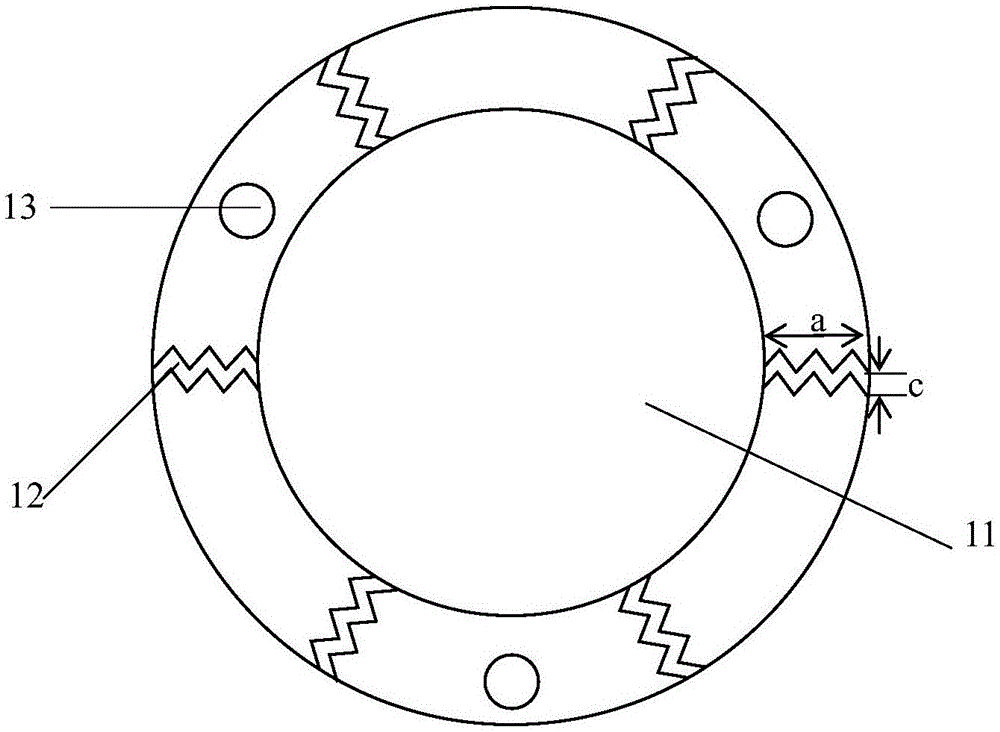

[0025] see figure 2 , is a grid structure diagram according to the first embodiment of the present invention. like figure 2 As shown, a grid hole area 11 with grid holes is provided in the middle of the grid, and a plurality of thermal strain grooves 12 are opened radially outward from the edge of the grid hole area 11 on the grid. These thermal strain grooves 12 run through the upper surface and the lower surface of the grid. In some embodiments of the present invention, the thermal strain groove 12 extends from the circumference of the grid hole area 11 to the edge of the grid along the radial direction of the grid. Preferably, the end of the thermal strain groove 12 facing the center of the grid keeps a certain distance from the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com