Low-pass filter based on TSV (Through-Silicon-Via) technology

A low-pass filter and through-silicon via technology, which is applied in the field of filters, can solve problems such as occupying a large board area, difficulties in filters and couplers, and technology that cannot meet the requirements of integrated circuits, so as to save costs, improve integration, The effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

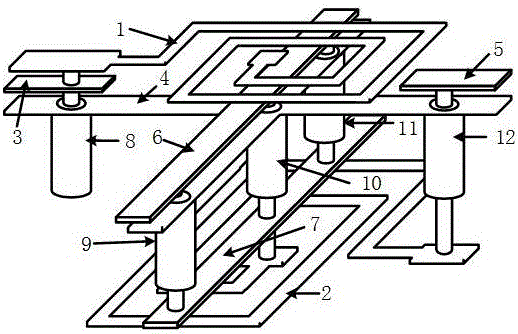

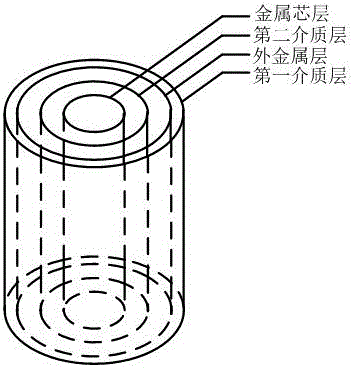

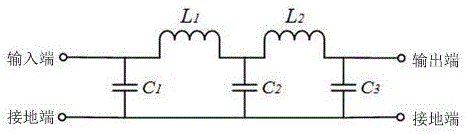

[0021] Such as figure 1 As shown, a schematic structural diagram of a low-pass filter based on the TSV technology of the present invention, a low-pass filter based on the TSV technology, including a spiral inductor unit, a rewiring layer and a TSV component, wherein , the spiral inductor unit is composed of a spiral inductor 1 and a spiral inductor 2 2, the rewiring layer includes an input terminal 3, an output terminal 5, a ground metal 4, an interconnection layer 1 6 and an interconnection layer 2 7, and the TSV component includes Five coaxial TSVs with the same structure, respectively TSV 1 8, TSV 2 9, TSV 3 10, TSV 4 11 and TSV 5 12, coaxial TSVs It includes the first dielectric layer, the outer metal layer, the second dielectric layer and the metal core layer in sequence from outside to inside, such as figure 2 As shown, a schematic diagram of the coaxial TSV structure in a low-pass filter based on TSV technology of the present invention.

[0022] The outer metal laye...

Embodiment 2

[0025] On the basis of Example 1, the spiral inductor 1 and the spiral inductor 2 both include a central end and an end, and the tops of the metal core layers of the TSV 9 , TSV 3 10 and TSV 4 11 pass through the interconnection layer One 6 is connected and connected to the central end of the spiral inductor one 1, the bottom is connected through the interconnection layer two 7 and connected to the central end of the spiral inductor two 2, the top of the metal core layer of the through-silicon via one 8 is connected to the input terminal 3 and the spiral inductor The ends of the first 1 are connected, the top of the metal core layer of the TSV 12 is connected to the output end 5, and the bottom is connected to the end of the spiral inductor 2 2 .

[0026] The second TSV 9 , the third TSV 10 and the fourth TSV 11 are connected in parallel for the purpose of connecting the equivalent capacitance of the TSV in parallel to increase the capacitance value.

Embodiment 3

[0028] On the basis of the above embodiments, the first dielectric layer is preferably one of a silicon dioxide layer, a silicon nitride layer and a silicon oxynitride layer, and is used to electrically isolate the TSV from the surrounding silicon substrate.

[0029] The second dielectric layer is preferably a hafnium dioxide layer with a high dielectric constant, and its function is to realize electrical isolation between the outer metal layer and the metal core layer in the TSV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com