Capillary electrochromatographic monolithic column modified with single-walled carbon nanohorns and preparation method thereof

A technology of single-walled carbon nanohorns and capillary electrochromatography, which is applied in separation methods, chemical instruments and methods, and other chemical processes, to achieve simple preparation processes, controllable reaction conditions, and ideal preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of monolithic columns for capillary electrochromatography modified with single-walled carbon nanohorns

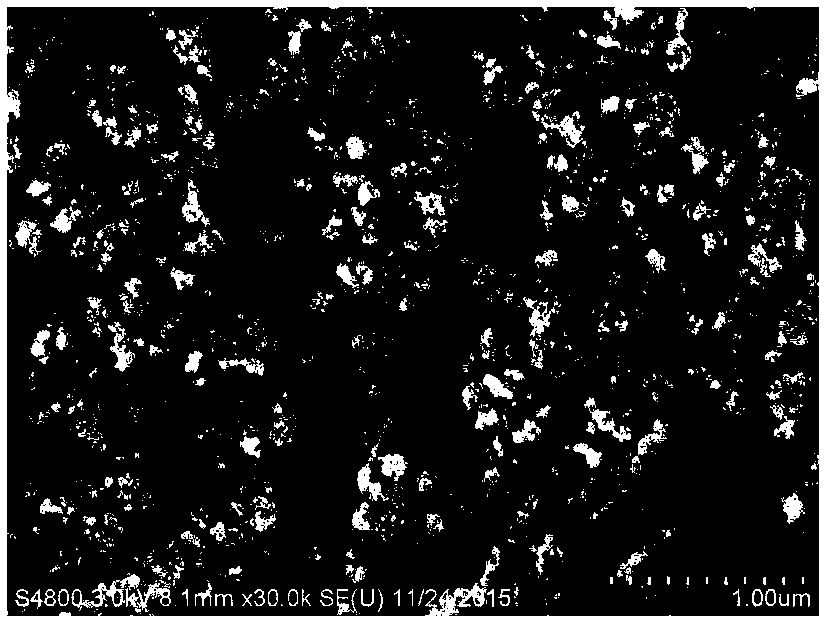

[0033] (1) Weigh 15 mg of single-walled carbon nanohorns to a test tube, add 30 mL of styrene, 25KHz ultrasonic treatment for 2.5 h to uniformly disperse the single-walled carbon nanohorns in styrene, and obtain a styrene dispersion of single-walled carbon nanohorns ( figure 1 is a TEM image of a styrene dispersion of single-walled carbon nanohorns).

[0034] (2) Weigh the styrene dispersion of single-walled carbon nanohorns (50 μL, 45.56 mg) obtained in step (1) and add it to 450 μL cyclohexanol (432 mg), and sonicate at 25 KHz for 2.5 h until the dispersion is uniform. Then DVB (50 μL, 45.95 mg), toluene (225 μL, 194.85 mg), AIBN (1.8 mg) and AMPS (0.9 mg) were added, and ultrasonic dispersion was continued at 25 KHz for 35 min, followed by nitrogen gas for 15 min to obtain a reaction mixture.

[0035] (3) Use a syringe to inject the reaction mixture o...

Embodiment 2

[0037] Preparation of monolithic columns for capillary electrochromatography modified with single-walled carbon nanohorns

[0038] (1) Weigh 15 mg of single-walled carbon nanohorns into a test tube, add 30 mL of styrene, and conduct ultrasonic treatment at 25 KHz for 2.5 hours to uniformly disperse the single-walled carbon nanohorns in styrene to obtain a styrene dispersion of single-walled carbon nanohorns.

[0039] (2) Weigh the styrene dispersion of single-walled carbon nanohorns obtained in step (1) (50 μL, 45.56 mg) and add it to 400 μL of cyclohexanol (384 mg), and sonicate at 25 KHz for 2.5 h until the dispersion is uniform. Then add DVB (100 μL, 91.9 mg), toluene (200 μL, 173.2 mg), AIBN (2 mg) and AMPS (1 mg), continue ultrasonic dispersion at 25 KHz for 35 min, and then blow nitrogen gas for 15 min to obtain a reaction mixture.

[0040] (3) Use a syringe to inject the reaction mixture obtained in step (2) into the pretreated 45cm capillary, and control the liquid inj...

Embodiment 3

[0042] Preparation of monolithic columns for capillary electrochromatography modified with single-walled carbon nanohorns

[0043] (1) Weigh 15 mg of single-walled carbon nanohorns into a test tube, add 30 mL of styrene, and conduct ultrasonic treatment at 25 KHz for 2.5 hours to uniformly disperse the single-walled carbon nanohorns in styrene to obtain a styrene dispersion of single-walled carbon nanohorns.

[0044] (2) Weigh the styrene dispersion of single-walled carbon nanohorns obtained in step (1) (50 μL, 45.56 mg) into 300 μL of cyclohexanol (288 mg), and sonicate at 25 KHz for 2.5 h until the dispersion is uniform. Then DVB (200 μL, 183.8 mg), toluene (150 μL, 129.9 mg), AIBN (2.2 mg) and AMPS (1.1 mg) were added, and ultrasonic dispersion was continued at 25 KHz for 35 min, followed by nitrogen gas for 15 min to obtain a reaction mixture.

[0045] (3) Use a syringe to inject the reaction mixture obtained in step (2) into the pretreated 45cm capillary, and control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com