Integrated low-temperature SCR (selective catalytic reduction) catalyst, preparation method thereof and application

An SCR catalyst and integrated technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem that the low-temperature denitrification performance of the catalyst is very high, cannot meet the working conditions of wet desulfurization, and the denitrification performance is not enough Ideal and other issues, to achieve the effect of excellent denitrification performance, uniform catalyst coating, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 1L of cordierite honeycomb ceramic carrier into 120mL of 0.5 mol / L cobalt nitrate aqueous solution, the cobalt nitrate solution is completely absorbed by the carrier, after standing for 2 hours, dry it in an oven at 100°C, and then bake it in a muffle furnace at 400°C After 4h, cobalt-modified cordierite honeycomb ceramics were obtained.

[0022] Put 1L of cobalt-modified cordierite honeycomb ceramic carrier into 120mL of 4.3 mol / L manganese nitrate aqueous solution, the manganese nitrate solution is completely absorbed by the carrier, after standing for 2 hours, put the carrier into 100 mL of concentrated ammonia solution In the process, concentrated ammonia water was absorbed by the carrier, dried in an oven at 100°C after standing for 2 hours, and then calcined in a muffle furnace at 400°C for 4 hours to obtain a monolithic SCR catalyst.

[0023] Catalyst evaluation method is the same as Comparative Example 1. The test results are shown in Table 1.

Embodiment 2

[0025] Change the 120mL 0.5 mol / L cobalt nitrate aqueous solution into 120mL 0.5 mol / L ferric nitrate aqueous solution in Example 1, and the remaining preparation methods are the same as in Example 1. Catalyst evaluation method is the same as comparative example. The test results are shown in Table 1.

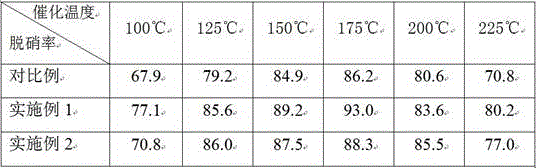

[0026] Table 1 Catalyst denitrification rate data

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com