Method for preparing carbon dots with multiple luminescence colors adjusted from coal pitch

A technology of coal quality and asphalt, which is applied in the field of preparing multi-color luminescent adjustable carbon dots, can solve the problems of high cost and low efficiency, and achieve the effect of low cost, wide application and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

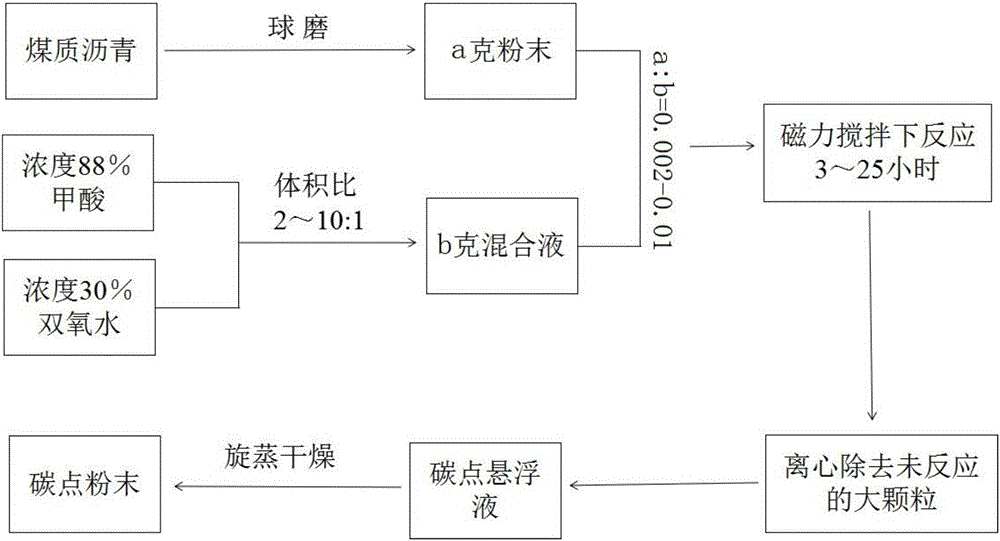

[0033] The method for preparing multi-color luminescent adjustable carbon dots by using coal-based pitch adopts the following steps:

[0034] (1) Get the coal-based pitch solid and put it into a ball mill tank, then carry out ball milling with a planetary ball mill to obtain smaller-sized coal-based pitch powder;

[0035] (2) Get 1 gram of ball-milled coal pitch fine powder and put it into a beaker, then add the mixed solution of 500 gram of formic acid and hydrogen peroxide; : 1 is prepared by mixing;

[0036] (3) Under normal temperature, react for 3 hours under magnetic stirring at a rotating speed of 400 rpm;

[0037] (4) Remove large particles in the solution after the reaction by centrifugation at 10000 rpm to obtain a suspension containing carbon dots;

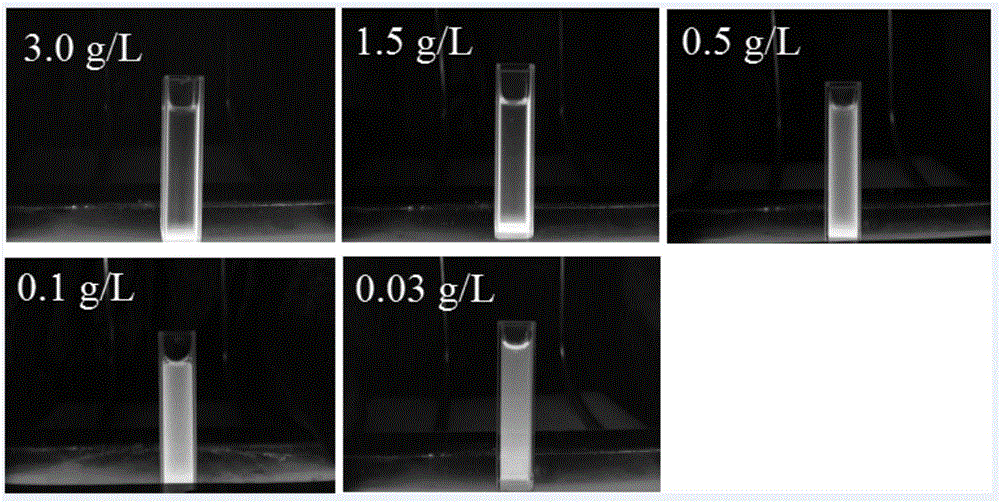

[0038] (5) Adjust the concentration M of carbon dots in the suspension to obtain different luminous colors: red light when M>1.8g / L; orange light when M=1.7~0.9g / L; orange light when M=0.8~0.4g / L Green light when L; ...

Embodiment 2

[0043] The method for preparing multi-color luminescent adjustable carbon dots by using coal-based pitch adopts the following steps:

[0044] (1) Get the coal-based pitch solid and put it into a ball mill tank, then carry out ball milling with a planetary ball mill to obtain a smaller-sized coal-based pitch powder;

[0045] (2) Get 1 gram of coal pitch fine powder after ball milling and put it into a beaker, then add the mixed solution of 250 gram formic acid and hydrogen peroxide; : 1 is prepared by mixing;

[0046] (3) Under normal temperature, react for 25 hours under magnetic stirring at a rotating speed of 800 rpm;

[0047] (4) Remove large particles in the solution after the reaction by centrifugation at 15000 rpm to obtain a suspension containing carbon dots;

[0048] (5) Adjust the concentration M of carbon dots in the suspension to obtain different luminescent colors: red light when M>1.8g / L; orange light when M=1.7~0.9g / L; orange light when M=0.8~0.4g / L Green ligh...

Embodiment 3

[0051] The method for preparing multi-color luminescent adjustable carbon dots by using coal-based pitch adopts the following steps:

[0052] (1) Get the coal-based pitch solid and put it into a ball mill tank, then carry out ball milling with a planetary ball mill to obtain smaller-sized coal-based pitch powder;

[0053] (2) Take 1 gram of ball-milled fine powder and put it into a beaker, then add 100 grams of formic acid and hydrogen peroxide mixed solution; the mixed solution of formic acid and hydrogen peroxide is mixed by volume of 88% formic acid and 30% hydrogen peroxide by volume be made of;

[0054] (3) Under normal temperature, react for 15 hours under magnetic stirring at a rotating speed of 600 rpm;

[0055] (4) Remove large particles in the solution after the reaction by centrifugation at 13000 rpm to obtain a suspension containing carbon dots;

[0056] (5) Adjust the concentration M of carbon dots in the suspension to obtain different luminous colors: red light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com