Oil-tea camellia cuttage and grafting integrated seedling breeding method

A technology of camellia oleifera and cuttings, which is applied in the fields of botanical equipment and methods, horticulture, cultivation, etc., can solve the problems of inability to meet the needs of high-quality varieties of camellia oleifera seedlings, damage to the root system of cutting seedlings, and pulling out of the seedbed, etc., and achieves grafting survival rate. The effect of high height, short seedling cycle and developed root system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

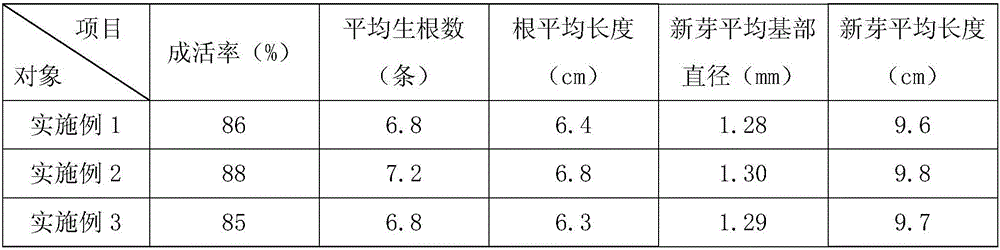

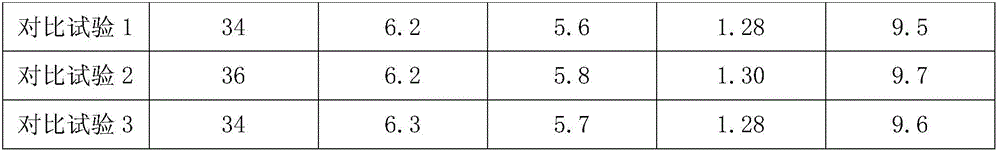

Examples

Embodiment 1

[0026] An integrated seedling raising method for Camellia oleifera cutting and grafting, comprising the following steps:

[0027] 1) Preparation of seedling substrate: Weigh the following raw materials in parts by weight: 33 parts of yellow heart soil, 11 parts of fine sand, 21 parts of plant ash, 5 parts of shell powder, 17 parts of edible fungus waste, 13 parts of compound fertilizer, 7 parts of oil tea cake powder, 14 parts of silkworm manure, 7 parts of dipotassium hydrogen phosphate, and 5 parts of zinc sulfate; the specific preparation process is as follows: after fully mixing the raw materials, pile them up, add water and mix well, and the amount of water added is limited to the bottom of the matrix pile without water flowing out. Natural stack retting for more than 3 months;

[0028] 2) Filling: Fill the seedling-raising substrate obtained in the previous step into the nutrient bowl and compact it lightly. The specification of the nutrient bowl is 12cm×14cm;

[0029] ...

Embodiment 2

[0041] An integrated seedling raising method for Camellia oleifera cutting and grafting, comprising the following steps:

[0042] 1) Preparation of seedling substrate: Weigh the following raw materials in parts by weight: 37 parts of yellow heart soil, 13 parts of fine sand, 23 parts of plant ash, 7 parts of shell powder, 21 parts of edible fungus waste, 15 parts of compound fertilizer, 9 parts of oil tea cake powder, 15 parts of silkworm manure, 8 parts of dipotassium hydrogen phosphate, and 7 parts of zinc sulfate; the specific preparation process is as follows: After fully mixing the raw materials, pile them up, add water and mix well, and the amount of water added is limited to the bottom of the matrix pile without water flowing out. Natural stack retting for more than 3 months;

[0043] 2) Filling: Fill the seedling-raising substrate obtained in the previous step into the nutrient bowl and compact it lightly. The specification of the nutrient bowl is 12cm×14cm;

[0044] ...

Embodiment 3

[0056] An integrated seedling raising method for Camellia oleifera cutting and grafting, comprising the following steps:

[0057] 1) Preparation of seedling substrate: Weigh the following raw materials in parts by weight: 47 parts of yellow heart soil, 14 parts of fine sand, 27 parts of plant ash, 9 parts of shell powder, 25 parts of edible fungus waste, 17 parts of compound fertilizer, 10 parts of oil tea cake powder, 18 parts of silkworm excrement, 11 parts of dipotassium hydrogen phosphate, and 8 parts of zinc sulfate; the specific preparation process is as follows: After fully mixing all raw materials, pile them up, add water and mix well, and the amount of water added is limited to the bottom of the matrix pile without water flowing out. Natural stack retting for more than 3 months;

[0058] 2) Filling: Fill the seedling-raising substrate obtained in the previous step into the nutrient bowl and compact it lightly. The specification of the nutrient bowl is 12cm×14cm;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com