A kind of mesoporous carbon supported palladium catalyst and application thereof

A technology of palladium catalyst and mesoporous carbon, which is applied in mesoporous carbon-supported palladium catalyst and its application field, can solve the problems of less application times, large amount of catalyst usage, complex catalyst components, etc., and achieve the effect of high activity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

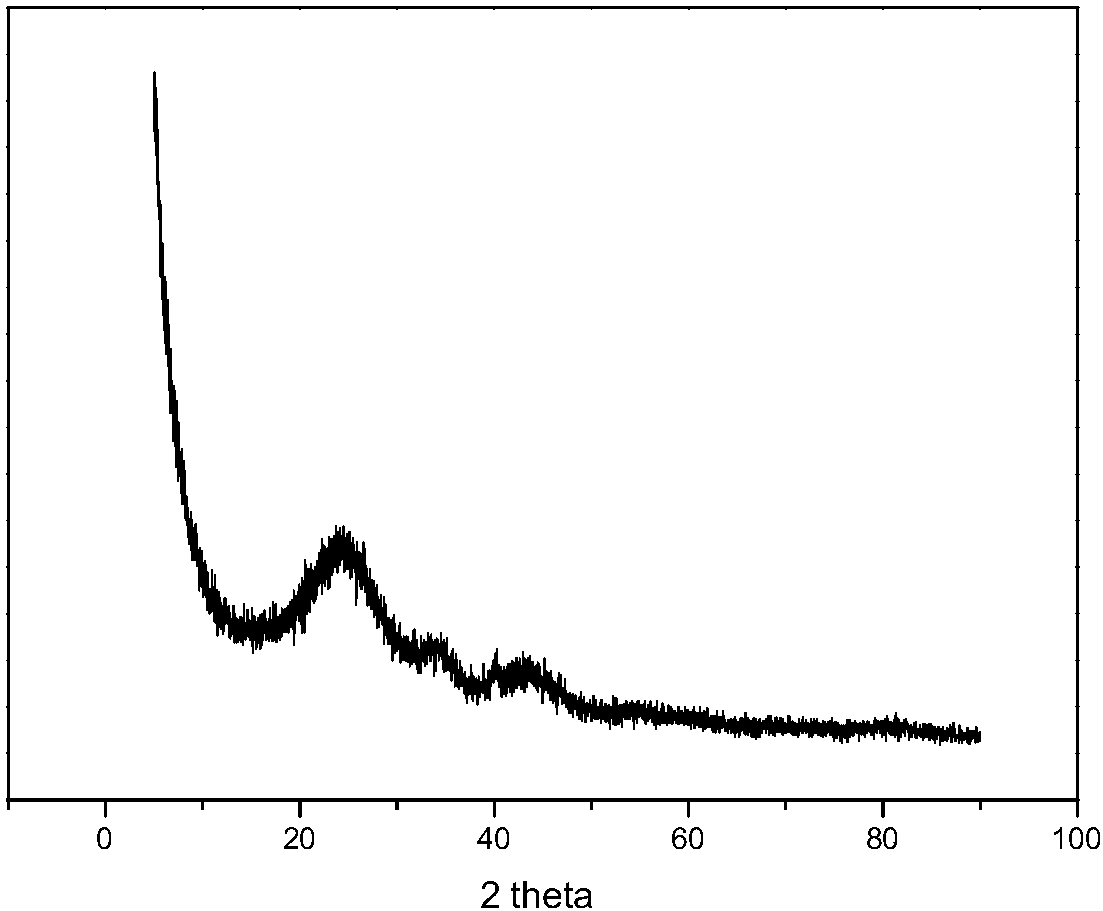

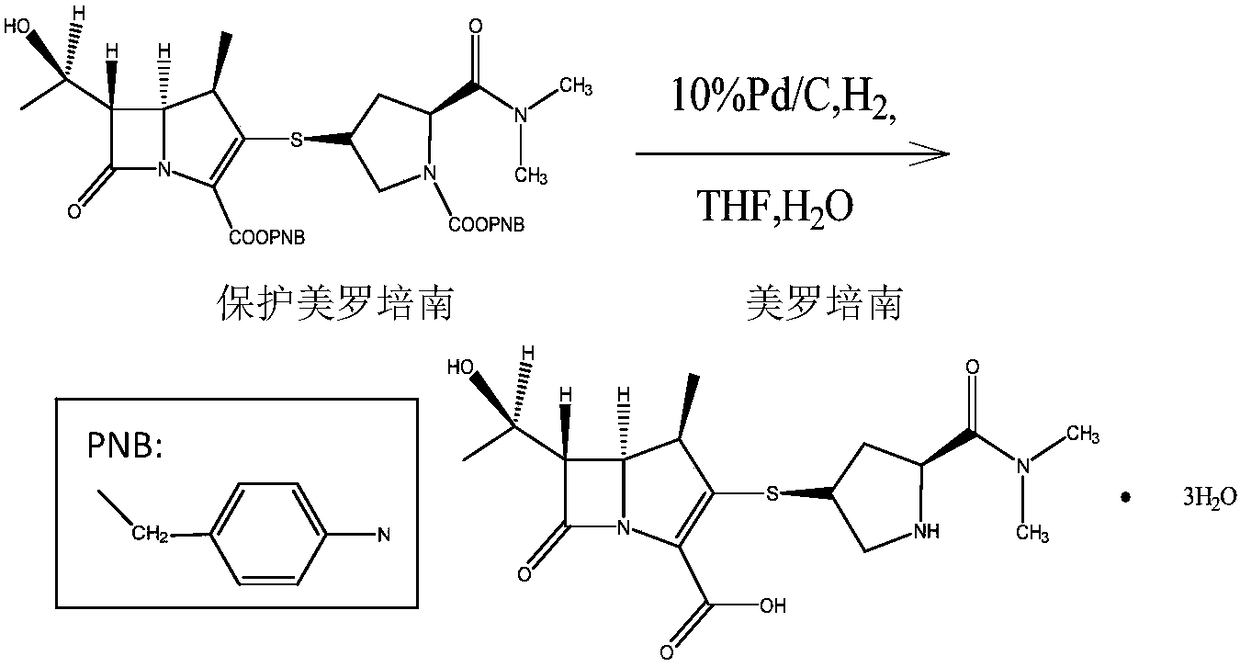

[0045] Physical and chemical parameters of mesoporous carbon: 1200m 2 / g, 1.65ml / g, PZC 7.2, the most probable pore diameter is 3.8nm, and the specific surface area of pores smaller than 2nm accounts for 3% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 10g of hydrogen peroxide, beat and stir, and control the temperature at 25°C. After 2 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnating solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnating solution with hydrochloric acid to make it lower than PZC 4.0; after the impregnating palladium solution is fully mixed with the mesopo...

Embodiment 2

[0047] Physical and chemical parameters of mesoporous carbon: 1500m 2 / g, 1.65ml / g, PZC 6.8, the most probable pore diameter is 3.5nm, and the specific surface area of pores less than 2nm accounts for 5% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 300g of hydrogen peroxide, beat and stir, and control the temperature at 10°C. After 5 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the corresponding mass of palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnation solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnation solution with hydrochloric acid to make it lower than PZC 5.0; after the impregnation palladium solution is fully m...

Embodiment 3

[0049] Physical and chemical parameters of mesoporous carbon: 1600m 2 / g, 1.85ml / g, PZC 7.2, the most probable pore diameter is 2.5nm, and the specific surface area of pores smaller than 2nm accounts for 10% of the total specific surface area. Preparation process: Pour 10g of mesoporous carbon into an aqueous solution containing 20g of hydrogen peroxide, beat and stir, and control the temperature at 25°C. After 3 hours, filter and wash until there is no residue; slowly add 37% concentrated hydrochloric acid dropwise to the palladium chloride powder with a loading capacity of 5% at room temperature until it is completely dissolved; then place the palladium solution in a beaker , add deionized water to prepare an impregnating solution with a total volume of 10 times the pore volume of the treated carrier, adjust the pH value of the impregnating solution with hydrochloric acid to make it lower than PZC 5.5; after the impregnating palladium solution is fully mixed with the mesop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com